NPE 2006 News Wrap-Up: Hot Shots: New Nozzles and Controls Add Sizzle to Runnerless Molding

Electrically driven valve pins, a low-cost alternative to valve-gating, mold-mounted temperature controllers, and new components for fast color changes are some of a host of new components and systems unveiled at the giant NPE 2006 show in Chicago this past June. (Some brand-new introductions since the show are also included in this report.) The news includes runnerless products aimed at everything from micromolding to shot weights up to 17.4 lb.

Electrically driven valve pins, a low-cost alternative to valve-gating, mold-mounted temperature controllers, and new components for fast color changes are some of a host of new components and systems unveiled at the giant NPE 2006 show in Chicago this past June. (Some brand-new introductions since the show are also included in this report.) The news includes runnerless products aimed at everything from micromolding to shot weights up to 17.4 lb. There’s also lots new in hot-runner temperature controls for two to 286 zones.

Valve gates go electric

At NPE, Ewikon showed its new Electrical Needle Drive for its HPS III-NVE 1 and 2 valve-gate systems. This was said to be an industry first when it was unveiled last year. It replaces pneumatic or hydraulic needle actuation and is especially suited to clean-room applications. Electric servo stepper motors are said to simplify installation and deliver precise control in 0.01-mm increments. The control system can readjust needle position automatically within one molding cycle if a deviation is detected. Ewikon’s electric needle drive unit can be used with nozzles having flow channel diameters from 3 to 9 mm, covering a broad shot-weight range.

By show time, electric needle drives were multiplying. Hasco claimed to have pushed the concept farther with its new electromagnetic needle-drive system in a 32-cavity close-pitch application. This unique system has an electromagnetic coil built into the cylinder housing. Current running through the coil creates a magnetic field that actuates the pin with no moving parts other than the pin itself. Hasco claims this is at least 25% less expensive than a servomotor system and is maintenance-free, easier to install, and allows for gate center spacing as tight as 0.18 mm.

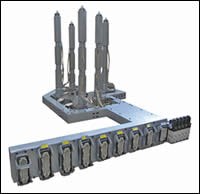

For this “Dart Tip” system, Hasco placed the Z1081 magnetic needle drive behind precision-guided, round ejector plates, each operating four valve pins. A mechanism on the back of the needle valve allows for exact adjustment of needle position, which Hasco says can minimize wear at the gate.

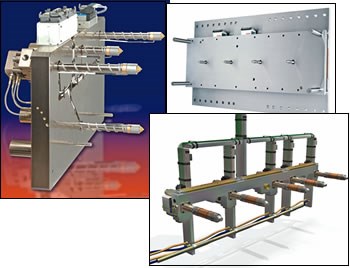

Heitec Heisskanaltechnik of Germany (represented here by Technoject) developed a new mechanical valve-gate actuation system to drive single or multiple needles simultaneously by an electric motor or conventional hydraulics or pneumatics. The single actuating bar connects with valve needles either in a row or other pattern. Locating the drive motor or air hydraulic cylinder outside the tool allows for smaller stack height and eliminates heat transfer from the tool to the drive. The system utilizes a visual position marker to help monitor needle positioning.

Other valve-gate news

Incoe introduced Control Gate, a lower-cost form of valve gating suited to less critical cosmetic applications where users need predictable and reliable gate opening but not sequential gate operation. The gate is opened by a spring-loaded piston and closed by air pressure on the piston.

Also new from Incoe is the Back-to-Back valve gate design for stack molds that eliminates offsetting the valve gates in order to reduce stack height. The valve gates are thus more compact, which allows valves serving each mold face to be positioned opposite each other in the manifold, which saves mold costs.

Incoe developed a new Multi-Pin valve gate for small parts that permits smaller pitch dimensions. Up to four pins are contained within a single, smaller cylinder mechanism.

Synventive rolled out two new types of valve-gate cylinders designed to retain maximum glass length in long-fiber parts. HYC 4018 and PNC 7518 cylinders are aimed at processing long-fiber pellets or direct compounding with continuous rovings. The cylinders have an optimized edge design, larger cross-section, tapered or cylindrical shutoff, and ±1.5-mm needle adjustment in the press. Cylinders can be actuated pneumatically or hydraulically.

New from HRSFlow Hot Runner Systems is the Under-Vacuum valve-gate nozzle that evacuates air or gas during two-shot overmolding to provide improved filling, reduced flash, and better part finish. The nozzles come in two versions, one with a vacuum applied through the first shot’s valve pin, and a second version with a vacuum chamber for each pin. HRS also showed a new line of rectangular valve gates.

Osco Runnerless Molding Systems introduced a new VGS valve gate-sequencing controller that utilizes 50% less energy than comparable units. The compact and quiet system can control pneumatic or hydraulic valve gate nozzles, triggered by time, linear position of the screw, or by cavity pressure. It can handle 4 to 16 zones, and no water-cooling is needed. It is supplied with a 6-in. display screen with an on/off display for each valve and can keep the operating parameters of five molds in memory.

A new compact, single-cavity valve gate (SCVG) for prototype tooling or low-production molding comes from Husky. The unit is self-contained and easy to assemble and disassemble, Husky says. Its patented stem reportedly improves reliability. SCVG is available in Ultra 500, 750, and 1000 sizes and VG or VX gating styles.

Husky is developing a new small valve-gate system for tight-access gating. At NPE, Husky displayed its new Ultra 350 valve gate in a 24-drop system with pitch spacing of 1 in. In addition, Husky has added a new sequential valve-gate control option for its TTC hot-runner temperature controller.

Profine Molds has added valve-gate systems to its lineup, offering up to 128 drops with nozzles for shot sizes up to 50 g. The front-mounted nozzles have needles actuated by a pneumatic cylinder on the manifold, as well as integrated pin guides and insulators to eliminate misalignment from thermal expansion.

New Zealand-based Mastip showed off its Mini Manifold Valve-Gate (MMVG) system for high-cavitation, close-pitch molding of small parts and its Manifold Valve-Gate (MVG) line for larger parts. MMVG is designed for non-sensitive materials like PP and PE and permits center pitches down to 35 mm. The pneumatic actuation circuit can be integrated with the backplate.

The MVG system is designed for high-speed, sequential filling of highly cosmetic gates. Minimum pitch spacing is 58 mm. It reportedly offers reduced molding pressure, increased molding window, and reduced gate-cooling requirements.

Manner rolled out a side valve-gating system for high-precision molding of small tube-shaped parts such as syringes and pipettes. The Sidegate series has cylindrical valve gates with combined pneumatic/mechanical pin actuation. An air-driven control pin is linked perpendicularly to the valve pins, which is said to eliminate problems such as stringing from hot tips or complicated vestige removal with a cold-runner system.

D-M-E has partnered with Polimold of Brazil, Latin America’s largest supplier of mold bases, to develop larger valve-gate systems for its Polivalve line. The line, previously suited mainly to commodity resins, will be enhanced to handle engineering materials and a wider range of shot weights from 120 to 7200 g. The system will be offered in two versions—a hot half or a Simplicity drop-in system. Fully integrated valve gates can be hydraulic or pneumatic.

Heitec is offering a larger version of its Starline edge-gate nozzles with a bolt circle that is more than 80 mm (3 in.) in diam. and handles up to eight tips. Previous maximum bolt circle was 58 mm diam. The nozzle can handle engineering resins due to the design of the tips, which extend to the part surface and produce no cold slug. The tips can be removed from the parting line without having to split the cavity block, a design said to allow for ample cooling and safer plastic sealing.

Herzog AG (represented here by Xaloy) redesigned its HP line of needle shutoff nozzles for higher strength and easier assembly. The ring and bracket components are now built in one piece for increased reliability. With pneumatic or hydraulic actuation, the nozzles handle injection pressures up to 43,530 psi and temperatures to 752 F.

At NPE, Yudo introduced Flexible Molding Control (F.M.C.) for valve gates. It balances flow through individual gates by adjusting the valve-pin position in 186 increments through a 15-mm stroke. A simple mechanical system using a rotating control shaft (one rotation produces 0.08-mm pin movement) can avoid the need for costly solenoids and sequential timers.

Yudo also came out with the Cool Pin system for valve gates, which removes heat from the manifold and prevents thermal bending of the valve pin. This simple approach consists of an air channel in the mold plate that holds the pin, which is said to keep the pin up to 180° F cooler than the manifold.

Mini nozzles are major

In keeping with the trend to smaller hot-runner systems, Incoe rolled out its DMT3 Micro Multi-Tip nozzles for small parts. They have up to six injection points within a 12-mm gate circle and pitch sizes down to 6 mm.

Ewikon developed a means of synchronizing valve-pin operation for small, closely spaced cavities. All needles are fixed in one actuator plate, which is operated either by a horizontal pull rail, a cam, or by hydraulically or pneumatically actuated pistons incorporated into the top clamp plate. All of these approaches reportedly achieve simultaneous movement of valve pins in extremely compact molds.

Gunther’s new Gate Guardian line of replaceable nozzle-tip inserts is designed for parts down to 0.04 g and pitch spacing as little as 9 mm. The gate is contained in the nozzle-tip insert and can be used with single- or multi-cavity tooling and even with highly glass-filled resins. The valve pins are adjustable for precise depth in the tool.

Softline offers a new line of nozzles for small caps and closures. Mikro nozzles can handle shot sizes down to 1 g. Softline previously offered nozzles only for larger parts.

Synventive extended its product range with a new line of nozzles and cylinders for small multi-cavity applications. The 04 C01 and 04 C02 series handle shot weights down to 0.1 g. Interchangeable heaters can mount on the front or rear of the nozzle. The 04 C02 nozzle has a head design that separates axial and radial positioning, which saves work for the toolmaker. Cables for the heaters and thermocouple are laid in the direction of the nozzle tip to permit easy changing from the front.

Synventive also developed the new HYC 2508 hydraulic valve-gate cylinder for these nozzles. Features include ±1-mm pin adjustment and patented active cooling of the pin guides. The pin is prevented from rotating to ensure the best cosmetic surface on freely shaped or contoured surfaces. A pneumatic version for clean-room use is in the works.

Manner introduced the Slimline valve-gate nozzle for small parts. The 8-mm-diam. nozzle can be used with cavity spacing down to 16 mm and shot weights down to 0.01 g. The tip has ceramic insulation.

As reported in February, Mold Masters introduced this year its Melt-Disk system for pinpoint direct side gating with angled tips. A heated disk acts like a mini-manifold in the cavity plate to ensure heat control in the gate area. Nozzles have two to eight gates and tips can be angled at 15° to 60°.

New F11 nozzles from Thermoplay of Italy (represented here by ALBA Enterprises) have 11-mm diam. and minimum pitch of 13 mm. They have very long tips that can feed an inside surface of a part.

For large parts, too

There was also hot-runner news at the other end of the size scale. Husky brought out a large nozzle to inject up to 2000 g/sec. This Ultra 1750 nozzle has melt channels up to 25 mm diam. It’s available in hydraulic valve-gate (VX) or thermal-gate (TS) versions.

Husky also has a new Ultra 1000 RP complete hot half for large automotive parts. Its new plate design (up to 68 x 56 in.) costs 15% less than the previous design. It carries up to 12 drops with hot-tip or valve gates.

Mold-Masters unveiled its Fusion series for large parts. Nozzles are up to 32 in. long and 1 in. diam. bore size.

Osco upgraded its Performance Series Nozzle (PSN) line by incorporating larger resin channels, larger gates, and a newly designed heater, while keeping the profile small to allow water cooling lines to be located closer to the gates. Larger channels put less shear on the resin and improve fill rates. New bimetallic MC-Mini coiled heater with a stainless-steel sheath is said to improve the heat profile for faster cycles and smaller gate vestiges.

More new hardware

Husky introduced its new Ultra Packaging (UP) series nozzle designed specifically for thin-wall packaging. The nozzle handles throughputs up to 300 g/sec in jobs running less than 3-sec cycles with pressures up to 35,000 psi.

Husky rolled out its new Split Sprue Bar (SSB) system suited to stack molds with up to four faces. Three sizes handle throughputs up to 1500 g/sec. The SSB device is configurable for offset stacks or tandem configuration. Stem-to-stem shutoff eliminates stringing and drool.

Osco developed a new hot sprue nozzle designed to fit inside unit dies (MUD, FITS, etc.) for small medical and electronic parts. Its HSN-Mini nozzle has 1.875 in. overall height and fits into a 0.72-in. diam. bore.

HRSFlow introduced two more nozzle types at NPE. They include Plus nozzles, which reportedly provide 20% to 30% energy savings due to improved materials in the body, tip, and end ring, as well as a new geometry for the tips and end bushing. The company also unveiled the Screwed Nozzle series that screws directly into the manifold and makes no contact between the mold and the nozzle cap.

D-M-E has replaced the carbide tips on its 250 series nozzles with molybdenum alloy tips, which give better heat transfer. This allows users to use lower temperatures, and the new tip alloy can handle a wider range of applications.

Incoe rolled out its new DF Gold series system in celebration of its up coming 50-year anniversary. The new line features two heater circuits in each nozzle to give uninterrupted operation in case one heater fails. The new Color Seal system for fast color changes traps material that remains in the gate-well area to prevent bleeding through to the new color. The DF line also has a proprietary tip coating for increased wear resistance and several new tip designs that bring increased application flexibility. Heat transfer between the system and the mold is decreased by ceramic supports.

Incoe also has new edge-gate nozzles with features from its DF Gold series, including twin heaters, coated tips for extended wear, and the color seal. The system is suited to applications such as syringe barrels.

Incoe introduced a new water-cooled insert that separates the hot runner from the cold mold to reduce part defects and surface-quality problems. Requiring minimal installation, it allows cooling medium to pass through the front areas of the gate insert as close to the parting line as possible.

Incoe also developed a new system that combines two heaters in one coil as a redundancy in case one heater fails. The Twin Heater system holds the same dimensions as previous Incoe nozzle heaters and is interchangeable with those designs.

Synventive developed a new series of nozzles for medium-sized parts. Its T16 (threaded design) and SR16 (support-ring clamp) nozzles expand its Kona XP line and handle shot weights from 850 to 1250 g/nozzle. Both lines have built-in heat pipes to provide uniform heating, 16-mm internal bore, lengths from 75 to 375 mm, and eight tip styles and valve-gate versions.

Yudo rolled out a new screw-in nozzle system suitable for large molds. The EZ-Free Screw system is a unitized system consisting of nozzles and a manifold block with associated wiring and plumbing in protective channels. Nozzles are not screwed directly into the manifold but are attached by a screw-in bushing. This reportedly frees the nozzles from the effect of manifold thermal expansion and allows for a much broader range of gate locations and nozzle lengths. Machining of plates is also greatly simplified and assembly time is reduced, Yudo claims.

Melt Design introduced a multi-tip nozzle with two to eight tips and center distances as small as 1.5 in.

New single nozzles from Thermoplay have a new heater that provides one uniform temperature zone for the entire nozzle, cutting costs and simplifying wiring.

Polyshot has developed a new manifold plate fusion technique said to facilitate color changes and improve overall performance in multi-material molds. Plate fusion involves machining the flow channels into the manifold plates, which are then joined in a proprietary process to produce smoother flow paths and no hang-up areas. Flow channels can be created with gradual turns and changing diameters (smaller to larger to smaller again). The technique eliminates the use of turn plugs as well as secondary honing of the flow path.

A new modular hot-runner system with a main feed bar that delivers melt to interchangeable sprue and nozzle carrier bars is new from Mold & Hot Runner Technology of Germany (represented here by Mold Hotrunner Solutions). The carrier bar reduces manifold machining time since the manifold is not cut from a single block, and it allows the manifold to be easily adapted to individual molds. Nozzles and sprue bars can be up to 1000 mm long with melt channels up to 22 mm diam.

New mixing tips

Desire for fast color changes prompted Husky’s new Ultraflow mixing tip. Husky says the tip’s mixing action ensures even dispersal of colorants and eliminates visible flow lines, while also homogenizing stresses and providing improved structural properties in molded parts. The standard design can handle up to 26,000 psi, while the high-pressure option withstands 35,000 psi.

Fast color changes, shot sizes up to 11 lb, and energy savings up to 60% are claimed for a new single-nozzle design from Thermoplay of Italy. It has interchangeable components, open valve-gate or hot-edge multi-tip configurations, and can handle all material types, including abrasive compounds. Thermoplay also has new nozzles designed to remove flow lines in parts with metallic or pearlescent pigments.

Temperature controls

Moldflow rolled out a new mold-mounted Altanium hot-runner temperature controller that is said to be the first such unit capable of handling 155 zones. The system is mounted on the stationary mold half using Moldflow’s patented MoldMount technology, which eliminates power and thermocouple cables to and from the mold. Mold mounting saves floor space, reduces installation and maintenance costs, minimizes downtime from damaged cables, and increases safety by reducing clutter around the mold. The control display can be mounted on the swing arm of the injection press or on a separate stand.

Moldflow also upgraded its Altanium line with new X and XE series of compact controllers for 1 to 255 zones of control. Replacing the Altanium C and CX lines, the X and XE series feature full thermocouple isolation, mold diagnostics, auto-tuning, virtual thermocouple rewiring, and slaving capability. The X series has 1° control resolution while the XE series has 0.1° resolution, expanded mold-error detection, and on-screen diagnostics.

Gammaflux has a new Power Priority control algorithm for tighter control of very small hot-runner nozzles. Available on its TTC and LEC lines, Power Priority smoothes the power output to individual zones.

Gammaflux also upgraded its TTC controller with “Mold ID” capability, which allows a controller to store and automatically recall setups for 63 injection molds. Also new are various transformer options and ability to enter setpoints in 0.1° increments.

Gammaflux expanded its LEC line of controllers for small hot runners with a two-zone module. Also, a new LEC network module allows linking multiple LEC controllers for up to 24 zones of control.

D-M-E plans to expand the capacity of its Integrity hot-runner controls to handle up to 48 zones in a single mainframe (up from 24 previously). It will also add a new slave feature that ties all zones to a master zone and a newly patented wiring feature that will enhance ease of use. Integrity controllers are designed for easy “daisy-chaining” to accommodate high-cavitation molds.

Incoe is now offering the M-Series modular temperature controller from S.I.S.E. of France. It handles 16 to 128 zones with continuous self-tuning PID control. Windows-based software allows user input from a touchscreen or keyboard PC interface.

HRS developed a new Fail-Safe controller for use with hot-runner components containing dual thermocouples and heaters to provide redundancy in case of a failure. The control monitors the thermocouples every 10 millisec and decides which of the two thermocouples to use. If need be, it switches automatically to the backup thermocouple for nonstop operation.

Manner unveiled its new HCS 2 series control for stack- or multi-cavity molds with six to 36 zones of control. It has comprehensive diagnostic and logging functions to make testing and startup easier, and uses internal bus communications and plug-in modules for easier upgrades. A touchscreen monitor can control multiple molds and displays all setpoints and actual values.

PSG offers a new mini temperature controller for up to eight zones and another system that handles up to 286 zones.

Plastic Engineering & Technical Services (PETS) introduced the Space Saving Module Control (SSMC) 951 controller for 12 to 60 zones.

Yudo has upgraded its CGF 770 controller, which handles six to 24 zones. It has a new touchscreen and a new sequential valve-gate timing program.

Thermoplay’s new PC-based THSync control can save and reload settings, chart temperatures historically or in real time, and configure zones into user-determined groups.

As reported in July, Athena’s new RMT dual-zone temperature controller is designed for hot runners and costs less than twice as much as a single-zone controller. It has two operator keypads, four LED displays, and discrete indicators for set and actual temperatures, alarms, and operating mode (closed-loop or manual).

Prewired and ready

ALBA introduced the ATS PTC line of Time Saver terminal junction boxes for five to 12 zones. They are prewired and use cage-clamp technology to secure and release control wires, eliminating the use of a screwdriver.

Heitec now offers prewired and premounted hot-runner systems using screw-in nozzles from its Easy-Line series. Prewired systems reduce shipping costs since hot-half mold plates are eliminated.

Related Content

Additive Masterbatches for Monomaterial PE Film Applications

Ampacet’s Biax4CE portfolio of additives and white color concentrates designed for MDO-PE and BOPE applications.

Read MoreReduce Downtime and Scrap in the Blown Film Industry

The blown film sector now benefits from a tailored solution developed by Chem-Trend to preserve integrity of the bubble.

Read MoreDSM Launches an AI Powered Color & Mechanical Properties Prediction Tool

Called Lucidiris, this prediction tool can reduce time to market when developing colors of high-performance materials for a variety of applications.

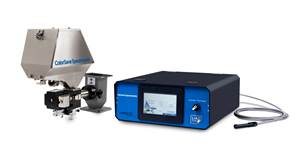

Read MoreColor-Measurement for Extrusion, Molding

System helps processors control the cost of quality due to color variations, using real-time color data for QC analytics and color optimization.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)