NPE 2006 News Wrap-Up: Materials

From PPs for frozen-food packaging to nylons and alloys that withstand the heat of circuit-board soldering or automotive paint ovens, NPE 2006 was rich in news of commodity and engineering resins and TPEs.

Food packaging that can go from freezer to microwave, stiff/tough nanocomposites, microcellular nylons with smooth surfaces, and crosslinkable TPUs are just a few of the intriguing new materials that made their debut at the big show in Chicago. More than three dozen new resins and compounds were introduced for automotive, electronics, building construction, sporting goods, and any number of other consumer and industrial applications. And that’s not all—see our show preview in June for coverage of more new materials that space won’t let us repeat here.

PP, LLDPE for frozen food

Four new polyolefins for injection molded frozen-food packaging were featured by two suppliers. Basell claims to be the first PP producer in North America to offer grades that can withstand freezer temperatures, opening the door to new applications in tubs, trays, and cups from 4 oz to 1.75 qt. Previously available PPs could withstand only refrigerator temperatures without susceptibility to cracking or breaking on impact, says Basell. Its two new grades reportedly also withstand microwave temperatures and are dishwasher safe.

One, Pro-fax EP390S, is a high-flow, high-impact copolymer for opaque, thin-wall injection molding. It has 35 MFR, drop-weight impact >45 ft-lb at -29 C, notched Izod impact of 3.6 ft-lb/in. at 23 C, and HDT of 185 F at 66 psi.

The other, Clyrell EC140R, is a nucleated heterophasic impact copolymer produced with the Catalloy process for clear, thin-wall injection molding. A 30 MFR resin, it boasts very high impact at both ambient and sub-zero temperatures and good resistance to stress whitening. It shows “no break” in Charpy unnotched impact tests at 23 C and 0 C. At -20 C, Charpy impact is 155 kJ/m2 unnotched and 4 kJ/m2 notched.

Meanwhile, Nova Chemicals launched two LLDPE injection molding resins for packaging ice cream and other frozen foods. Surpass IFs542-R is for tubs and IFs730-R for lids. They are made with the Advanced Sclairtech process utilizing a proprietary single-site catalyst that is said to produce resins that process at lower temperatures and shorter cycle times. IFs542-R has 0.942 g/cc density, 60 MI, tensile yield strength of 3176 psi, yield elongation of 10%, and flexural modulus of 135,465 psi. IFs730-R has 0.930 density, 85 MI, tensile yield strength 2205 psi, yield elongation of 12%, and flex modulus of 76,290 psi.

More news in packaging

Other new packaging materials include a family of foamable SMA copolymers, metallocene-based PP (mPP) grades for injection molding and cast film, and a PET bottle resin PET that’s said to raise the bar for uv protection.

Nova Chemicals’ new foamable SMAs for microwaveable packaging are alternatives to PS foam and solid filled and unfilled PP. Dylark FG resins consist of blends of crystal and impact Dylark FG grades that can be tailored for foams that can be processed on existing PS foam extrusion equipment with direct gas injection or chemical foaming.

These foamable resins reportedly resist temperatures from the freezer up to 250 F and produce significantly lighter parts than solid PP at 20% to 25% lower part cost, Nova claims. Foam take-out containers made with these resins reportedly maintain their rigidity and provide insulation performance during travel and during microwaving.

Basell has two new grades of Metocene mPP homopolymers for injection molding, both of which are nucleated and have very narrow molecular-weight distribution. They are said to provide low warpage, high clarity, good stiffness, and high flow (achieved in the reactor without “visbreaking”). HM640T is a high-flow (60 MFR) resin suited to thin-wall food containers or CD/DVD cases. It has a tensile strength of 5200 psi (36 MPa), flex modulus of 220,000 psi (1515 MPa), notched Izod impact of 0.5 ft-lb/in. (27 J/m), and haze value of 7%.

HM1753 is a very high-flow resin (140 MFR) that contains an antistat. It is aimed at thin-wall food containers, multimedia packaging, and housewares. It has a tensile yield strength of 5800 psi (40 MPa), flex modulus of 275,500 psi (1900 MPa), notched Izod impact of 2.3 kJ/m2, and haze of 10%.

Basell’s new mPP for cast film, Metocene X11291-55-1, is a 9.5 MFR homopolymer that can be used in packaging, candy twist wrap, photo albums, laminations, geomembranes, and fibers. It boasts exceptional clarity and sealability due to the combination of very narrow MWD and low melting point of 293 F (145 C). This is said to be a clean-running resin with low smoke and volatiles that contains no peroxide and has low levels of extractables.

A PET resin with new integral uv-barrier technology is said to set a new standard for uv protection, extending the shelf life of packaged materials like vitamins, health and beauty aids, and beverages. Introduced by DAK Americas, Laser+ UV combines DAK’s own proprietary technology with ClearShield UV 400 uv absorber from Milliken Chemical.

PET itself absorbs uv light up to a wavelength of approximately 320 nm. Standard uv absorbers can extend that protection up to 360 to 370 nm. But that’s not enough for sensitive ingredients like vitamins and natural and artificial colors, DAK says. Laser+ UV PET absorbs uv up to 390 nm.

MDPE for floor heating

A fractional-melt MDPE that has been used in Europe for in-floor heating pipe for over a decade was introduced at NPE to North America by Dow Plastics. “Radiant floor heating is becoming more popular, particularly in the Northeast. We are seeing this in both the retrofit area and custom homes and expect to see more in new construction in the future. Annual market growth is estimated at somewhere between 8% and 12%,” says Heather Lau, Dow’s North America market manager for plastic pipe.

New Dowlex 2344 is a 0.933-g/cc, 0.7 MI octene copolymer with controlled side-chain distribution that is said to provide excellent ESCR plus very good long-term hydrostatic strength at high temperature without the need for crosslinking. It is the only non-crosslinked PE with a Plastic Pipe Institute (PPI) listing at 180 F. With 79,000 psi flex modulus, Dowlex 2344 is more flexible than crosslinked PE, facilitating easier installation. It is also more easily recyclable and is priced competitively with crosslinked PE but could provide faster processing without the crosslinking step. It costs at least 50% less than copper pipe.

New/old source of CPVC

PolyOne Corp. has launched the first grade in a line of CPVC molding and extrusion compounds for high-temperature applications, including hot-water pipe and fittings and components for pools and spas, windows, and electrical products. These are the first CPVC products for PolyOne, which traces its heritage back to the former BFGoodrich Co. The former Goodrich TempRite CPVC line now belongs to Noveon Inc.

PolyOne’s Geon CPVC compounds will include transparent and opaque grades and are said to offer easier processing than competitive products. One grade is initially available for hot-water pipe and fittings.

Nanocomposite news

Continuing R&D in nanocomposites was evident in announcements at the show. DuPont gave a preview of new engineering nanocomposites that will be introduced in 2007. These include resins containing DNM, a high-aspect-ratio nanoclay that reportedly can provide substantial property improvements at 1.5% to 5% loadings. For example, DuPont reports that 1.5% of DNM in glass-reinforced PET boosts HDT by 10° to 15° C. Adding DNM also allows reducing glass-fiber content (and resulting weight) while retaining equivalent properties. DuPont noted that small amounts of DNM can improve high-temperature creep resistance up to 30% while enhancing the stiffness-toughness balance of PET. DuPont is also examining DNM in nylon.

Specialty compounder RTP has developed new nylon nanoclay compounds for barrier uses in automotive fuel systems. The new compounds are claimed to provide a monolayer solution for small-engine fuel-tank makers who must meet new fuel-emission standards. Organically treated nanoclay particles create a “tortuous path” for diffusion of fuel molecules through the tank wall. Transmission rates can be cut by 50% to 75%, RTP claims.

Reduced permeability is also seen in food packaging, where nylon 6/nanoclay compounds reduce oxygen transmission by 75% to 80% versus straight nylon 6. This can allow thinner and lighter packages with similar shelf life. The nanoclay compounds also improve mechanical and thermal properties at low loadings (2% to 8%) with minimal impact on specific gravity.

Better surface for nylon

Trexel and Rhodia Engineering Plastics announced new material and process developments that improve the surface finish of nylon parts molded with Trexel’s MuCell microcellular foam process. Nylon has been used with the MuCell process but surface appearance has been a limiting factor. Working with Trexel, Rhodia adjusted material formulations to overcome the natural tendency of gas to migrate to the interface between the melt and mold while being injected and thus create splay. In addition, Trexel has refined the parameters of the injection process, including injection-speed profiles, gate sizes, and mold and melt temperatures to get the improved surface.

Rhodia has adapted its Technyl Star technology to create new Technyl XCell nylon 6 and 66 grades optimized for the MuCell process. Technyl XCell nylon 6 offers high flow (more than 200% greater spiral flow length than standard nylon) and good property retention while maintaining surface appearance. The 66 grade also offers excellent property retention and good surface appearance, along with 160% higher spiral flow. The MuCell process brings 10% less weight, lower cavity pressures, reduced processing temperature, and ability to use smaller presses. Application areas include rocker covers, engine covers, and air-intake manifolds. Under the agreement, Trexel will work exclusively with Rhodia on nylon applications.

DuPont has new halogen-free and high-flow grades of high-heat semi-aromatic nylons. Zytel HTN53G50LRHF is a 50% glass-filled grade with 20% higher flow than comparable products. Halogen-free Zytel HTNFR52G30NH is a 30% glass-filled PPA (polyphthalamide) that is compatible with emerging electronic recycling systems. It can withstand high-temperature circuit assembly with lead-free solder, and it has good strength, stiffness, and toughness over a wide temperature and humidity range. For high-voltage applications, this grade also has a comparative tracking index (CTI) greater than 600 v, the highest IEC 60112 classification. This allows closer spacing of current-carrying parts.

In other high-temperature resins, DuPont has developed a new PCT polyester compound for small, hotter-running automotive ignition coils. Thermx TE4001 contains glass fiber and flake and boasts good high-temperature electrical properties. Its dielectric strength remains virtually constant (41 to 42 kV/mm) from ambient temperatures to 200 C. Its maximum operating temperature in ignition coils is 170 C. It also has higher flow than competing materials such as modified PPO. It exhibits good adhesion to epoxy coil encapsulants.

Advances in TPEs

As reported last month, a developmental family of novel thermoplastic olefin block copolymers (OBCs) was unveiled at NPE by Dow Chemical. Infuse OBCs are lauded as a breakthrough in olefinic elastomer chemistry due to their unique block structure, which reportedly delivers novel combinations of properties and processability at a “cost in use” competitive with materials such as TPVs, TPUs, and styrenic block copolymers. These materials also boast performance advantages over EVA and flexible PVC for applications in flexible molded goods, extruded profiles, hose, tubing, elastic fibers and films, foams, coated fabrics, tapes and melt adhesives. Developed with “post-metallocene” catalysts, the first Infuse grades will be announced later this year.

Also reported last month was Dow’s new family of TPOs for large-part thermoforming. The first grade, Inspire EFP 500, is a 0.5 MFR material with a flexural modulus of 300,000 psi aimed at sporting goods, automotive components, RV parts, canoes, kayaks, all-terrain vehicles, and tractors.

GLS Corp. introduced new TPE alloys as replacements for more costly silicone and PVC compounds in applications requiring both clarity and heat resistance. The Versaflex CL2200 Series has water clarity, excellent heat resistance in boiling water, and USP Class VI acceptability for food and drug containers. It is designed for overmolding onto PP and other olefinics. Injection grades are available in 42 and 50 Shore A hardness.

TPUs extend their range

A range of new TPU developments at the show include chemically crosslinked materials that are said to perform similarly to or better than castable thermoset polyurethanes. X-Link TPUs from PriPro Polymers reportedly provide the superior properties of castable PUR systems with the manufacturing advantages of injection molding or extrusion and 50% lower cost than castable systems. PriPro has developed proprietary additive and processing technology that can be applied to all commercially available TPUs with either ester or ether backbones and hardnesses from 60 Shore A to 75 Shore D.

The proprietary additive loading of 3% to 8% can be tailored to optimize certain properties. The TPU must be post-cured and aged for two weeks to achieve full mechanical properties. Applications include skateboard wheels, in-line skates, automotive seals and wiper blades, and industrial parts. Along with injection molded and extruded TPUs, PriPro is developing custom masterbatches and expects to license the technology.

BASF introduced Elastollan 1190A16 TPU, which is NSF approved for lining cured-in-place epoxy pipe for potable water. It is claimed to be the only TPU that complies with the NSF standard without limitations on surface exposure or time.

BASF also launched Elastollan C85A15 HPM, a high-heat TPU that meets the ISO 6722 temperature classification Type D (150 C, 3000 hr) for cable jacketing. Typical TPUs are said to achieve only Type C classification (125 C, 3000 hr). The plasticizer-free grade is aimed at under-hood uses, anti-lock brake cables, and general cables. This grade extends the Elastollan HPM series into harder grades (above 80 Shore A).

Three new TPUs from Noveon provide improved resistance to biodiesel and other fuels, as well as styrene, perchloroethylene, and acetone. Among them is Estane HS85DN (85 Shore D), said to be a new class of polymer with very low permeability to hydrocarbons. The water-clear material also has high stiffness. Better chemical resistance is also offered by Estane X-1181 (85A) and Estane X-1130 (90A). X-1181 swells only 1% after a week’s immersion in biodiesel fuel, compared with 3% for a standard 85A polyester TPU. Targeted applications include fuel hoses, valves, and filter housings; storage devices; and sports and recreational equipment.

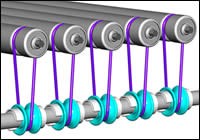

Noveon also launched a TPU with improved durability for conveyor drive belts. Round drive belts made of Estane X-1222 reportedly have three times the life expectancy of competitive TPU belts. The material boasts superior creep resistance, which results in low abrasion and low belt slippage. Dura-Belt, a manufacturer of urethane belting for power transmission and conveyors, is the first to offer belts made of Estane X-1222. It offers an unprecedented two-year warranty on the belts.

New conductive compound

An as-yet unnamed U.S. compounder is expected to be the first to sell commercial quantities of a unique highly conductive compound called ElectriPlast, developed by Integral Technologies Inc. The material consists of 6- to 25-micron conductive fibers (metallic or carbon) plus a special chemical dopant in any of a variety of base resins. A special dispersion technique is part of the technology, which has been licensed to Heatron, a maker of heating elements in Leavenworth, Kan. Prototype antennas are among several other products that have also been produced from ElectriPlast.

EPS for concrete forms

New EPS beads from Nova Chemicals are said to deliver “best-in-class” performance for insulated concrete forms (ICFs). Nova’s EPS 35MB-ICF grades are said to offer substantial processing advantages due to shorter molding cycles and pre-foam aging times, as well as improved yields from easier filling and improved packing within molds. In addition, these beads reportedly mold smooth-surfaced ICFs that are easily finished. They also boast good dimensional stability and significantly higher flexural strength than competing products, which result in improved reliability for builders.

More new styrenics

New ABS/nylon alloys were introduced by Lanxess Corp. Triax 3250 is an on-line paintable, static-dissipative grade for auto body panels and Triax 3210 is a general-purpose grade for consumer and electronics applications. Both materials can withstand the high oven temperatures used in electrostatic painting. Triax 3250 reportedly eliminates the need for a conductive primer. The materials are said to match the performance of competitive PPO/nylon alloys while also offering improved flow and stiffness and reduced CLTE.

Lanxess also launched two soft-touch products for extruded sheet capstock. Lustran ST 4566 ABS and Centrex ST 4766 weatherable ASA offer a leather or vinyl feel for interior and exterior RV, truck, bus, and marine applications. They provide low gloss and uniform appearance after forming.

Related Content

Advanced Plastomers for Production of PE-Based Sealant Resins

Nova Chemicals’ new Astute products are suitable for a broad range of applications including food packaging, heavy-duty sacks and e-commerce.

Read MoreResins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

Read MoreTracing the History of Polymeric Materials -- Part 29: Polyurethane

This material family has unparalleled versatility, not only in terms of the forms the material can take, but in the different ways in which it can be processed.

Read MoreMulti-Purpose TPV with Post-Industrial Recycled Content

Teknor Apex’s new Sarlink R2 3180B TPV offered with 25% PIR content.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.png;maxWidth=300;quality=90)