NPE News in Blow Molding

While occupying a relatively small category of exhibits, blow molding will present no lack of innovation at NPE.

While occupying a relatively small category of exhibits, blow molding will present no lack of innovation at NPE. Perhaps the most dramatic news will be a technology that doubles the output of a standard shuttle machine. Another first is foaming PET bottles. Continuing a gradual trend in blow molding, at least three companies will present new energy-saving all-electric machines. In addition, new reheat stretch-blow units target containers of up to 10.5 gal. Two companies will present wheel machines aimed at smaller bottles. And two new multi-layer barrier approaches will be shown for the first time.

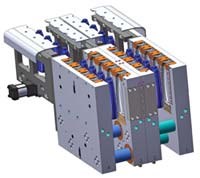

SHUTTLE OUTPUT DOUBLES

Bekum will showcase an industry first: Its mid-sized double shuttle, BM-406D, will be outfitted with novel technology that doubles its output capacity at modest cost and while maintaining a compact footprint. A reportedly unique twin-row extrusion head from W. Mueller in Germany is paired with an equally unique (patent pending) Multi Parting Line (MPL) mold from Fidelity Tool and Mold, Batavia, Ill. Bekum added double-row calibration and parison cutting, as well as special servo-electric takeout. With these modifications, the BM-406D can mold over 5000 15-oz oval shampoo bottles/hr with 16 cavities. The same bottle can run 32 cavities on a BM-806D with MPL technology at over 10,000/hr. MPL is also available on Bekum’s H-Series shuttles and long-stroke machines.

FOAMING PET BOTTLES

Another first is foamed PET bottles using gas injection. In 1998, HDPE shampoo bottle were foamed with chemical blowing-agent masterbatch, but Plastic Technologies Inc. (PTI) has developed the “oPTI” process for foaming PET bottles with the MuCell microcellular process licensed from Trexel Inc. It requires no modification of the stretch-blow equipment. Nitrogen gas is mixed with the melt in a modified injection barrel on the preform machine. Foam bottles are pearly translucent to opaque and can be lightweighted up to 5% because the foam adds stiffness. Foaming also adds a non-slip surface and improves replication of details like embossed logos. PTI says its oPTI process is applicable to PEN and PLA.

ALL-ELECTRICS HUM

It introduced an electric/hydraulic hybrid in 2007, and now Uniloy Milacron Germany/B&W will launch its first all-electric model. The single-station UMS 4E.S, at the booth of FGH Systems, its U.S. turnkey package provider, is a new continuous-extrusion shuttle unit for containers up to 1.5 liters. It is based on the hydraulic UMS 4, with electric servo drives replacing hydraulic cylinders. The machine has a center-flow extrusion head from Willi Mueller, and features a new torque motor from Baumuller on the grooved-barrel extruder. The machine uses separate servo drives to control extrusion and clamping (4 metric tons). Clamp force build-up is generated by direct drives that transfer the force directly to the platens without additional mechanics or lever systems. In this configuration, the blowing process requires no energy to keep the mold shut. Energy consumption related to machine movements is reduced by around 70% compared with a hydraulic machine. Overall machine consumption, including machine movements, extruder drive, and heating, is said to be around 30% lower. The model operates at a 69 dbA noise level. A 12-ton version will be released next.

Techne S.p.A. of Italy will show its all-electric Advance 510/4 high-production continuous-extrusion machine, which was introduced at the K 2007 show. The modular unit handles up to 40 cavities. (More details were reported in Sept. ’07 and Jan. ’08.) Techne will also introduce a hydraulic 10000S900 three-layer coex machine for large containers, designed for use with post-consumer regrind.

Plastimac of Italy, exhibiting with its U.S. distributor, American Jet Stream, just came out with two electric machines. These are the Plastiblow PB5E/DL, a double-station unit with a 50-mm extruder and a triple head for production of 1L HDPE or PP bottles at 2300 units/hr. The head design was improved to allow more rapid color changes. The controller allows for the rejection of faulty containers based on a range of possible defects.

Plastimac also brought out the Plastiblow PB1E/D electric model for HDPE shampoo bottles. It is a double-shuttle unit with a 60-mm extruder and triple head. An in-line detection system classifies defective bottles while they are being rejected.

SMALLER WHEELS ROLL

Smaller wheel-type machines designed for coextruded containers come in two new models from Graham Engineering. Its Mini Wheel line, which started with a 12-station unit, now includes new nine- and 10-station versions. These give small and mid-sized molders an alternative to a five- or six-parison, double-sided shuttle.

Wilmington Machinery will roll out a new dual-parison wheel for up to 0.5L bottles. Its 50-cavity Small Bottle (SB) system can produce monolayer or coextruded bottles with up to six layers. It can process more than 2000 lb/hr of HDPE and mold up to 18,000 bottles/hr. Wilmington will also roll out an updated version of its Series V wheels for large bottles.

LARGER PET MACHINES

Sipa of Italy will expand its linear reheat stretch-blow series with the new SFL2 model capable of producing two 6.6-gal PET containers with a 65-mm neck finish or a single 10.5-gal container with 85-mm neck.

Wei Li Plastics Machinery of Hong Kong will show its most popular two-stage reheat stretch-blow machine, the WL-MP02. The model uses German and Japanese electric and pneumatic components. The open-top design induces natural air-flow into the machine, as hot air raises and cool air flows in at the bottom, eliminating need for an exhaust fan. A special mechanical mold locking system reportedly withstands 35 bar (507 psi) blowing pressure and leaves a smooth parting line.

Aoki Technical Laboratory of Japan will introduce the model SBIII-500LL-50 all-in-one injection stretch-blow machine. This is a new size in its three-station rotary line.

MORE MACHINES

Kautex Machines will show what it calls the largest long-stroke, dual-station shuttle. The new Model KLS14-100D is said to allow for high cavitation and ease of changeover. The unit will make 16 three-layer containers on 85-mm center distances at the show. Kautex also developed a line of energy-efficient extrusion systems for blow molding machines that are said to achieve 30% higher output with 30% lower energy use.

During the show, Kautex will also organize visits to a local medical molder that has harnessed a conventional shuttle (model KCC20D) in a lights-out production cell. Hospital urine containers are leak tested, weighed, capped, boxed, and palletized.

Pavan Zanetti of Brazil will present its new BMT 5.6D/H Multiline extrusion blow machine with two 70-mm extruders and twin sextuple heads with a 75-mm centerline distance. The unit can handle four molds with six cavities each.

Pet All Manufacturing will demonstrate an 88-ton IBM 300/700 injection-blow machine with an inverted head, B&R controller, and Rexroth cylinders. Its machines are built in China and Taiwan and assembly is completed in Canada.

Davis-Standard will introduce the MACO 6500RSE blow molding control system with hardware from Eurotherm and proprietary software from Davis-Standard. It’s said to be a cost-effective upgrade from the MACO 6500RS introduced in 2005. It is available for retrofit and offers a number of enhancements.

BARRIER TECHNOLOGY

Kortec will show two types of multi-layer barrier technologies for the first time in North America. One is Gamma-Clear technology licensed from Ball Corp. for producing containers with PET-like clarity. The technique involves stretch-blowing clarified PP with an EVOH barrier layer as an alternative to glass in hot-filled or retorted food and beverage containers. Kortec is licensed to sell this technology only outside North America.

Kortec will also show ThinWall high-barrier technology for packaging. The approach yields lightweight cups and containers as a replacement for small metal cans.

Related Content

Mold Opaque White PET Bottles – Without Pigment

Trexel and Husky are cooperating on molding recyclable opaque white preforms for PET bottles, which provide a light barrier using foam instead of pigment.

Read MoreUnderstanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

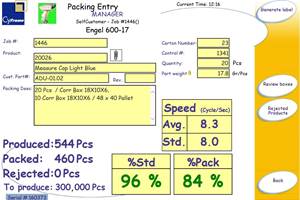

Read MoreUse Interactive Production Scheduling to Improve Your Plant's Efficiencies

When evaluating ERP solutions, consider the power of interactive production scheduling to effectively plan and allocate primary and secondary equipment, materials and resources on the overall production capacity of the business and conclude that this is a key area that cannot be overlooked.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More