NPE2018 New Technology Focus: Mold Components, Supplies, Maintenance

Advances include new approaches to tool maintenance and monitoring.

Milacron’s DME business unit is launching a new quality certification for its American standard mold base. In addition to these mold bases, The new DME Machined-4-Quality standard applies to the company’s American standard mold base A-Series, B-Series, AX, X and T-Series lines.

Meusburger’s new E 3064 guide for inclined pins reportedly provides optimal surface contact with the inclined pin, resulting in a high force absorption. Meusburger notes that the machining of the pocket in the slide is possible without inclining, and that the slide stroke can be customized by adjusting the guide’s position.

Meusburger’s new E 1307 fine-centering unit is flat and requires minimal installation space. The DLC-coated centering elements are available with or without fixing holes, which enable maximum flexibility in design and reduce wear. Meusburger designed this centering element to be as small as possible for exact centering of individual inserts. The product features a compact design and defined installation positions, which prevent incorrect mounting of centering parts. Ensuring minimal wear, the unit is suited for use in clean rooms.

In mold-base technologies, Hasco is highlighting locating guide bushings with a circlip groove and new, individually printable nameplates for custom identification of molds.

CUMSA is showing two vacuum devices to remove trapped air from the mold cavity. The Double Action Vacuumjet (VB) and the Smart Vacuumjet (SV) are based on the Venturi principle, so that only 6 bar (90 psi) of compressed air are needed to pull out gases at rates up to 60 liters/min. CUMSA adds porous inserts and/or laminar vents in critical areas of the mold, including at end of fill, to remove gases during injection and create less resistance to melt flow.

The Smart Vacuumjet (SV) senses and displays the level of vacuum achieved in the cavity. If the desired vacuum cannot be achieved after 5 sec, but levels exceed -200 mbar, the SV will close the valve and start injection, indicating the maximum achieved vacuum with red numbers (instead of green) in the display. If, however, after that time vacuum does not reach the minimum threshold, the unit will not send the signal to start injection to avoid production of low-quality parts, with the display indicating the cause of the production interruption.

The patent-pending Linked-Valve system of linkages from Plastixs allows a single lever to simultaneously operate mold-cooling supply and return lines. The product is currently available for use on both 1- and 1.5-in. Smartflow aluminum manifolds and Plastixs 1- and 1.5-in. compact stainless-steel manifolds.

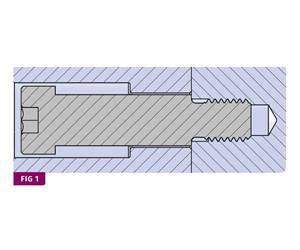

DMS’s NPE2018 display includes the Almo worm-gear device that enables inserts to be tightened and released inside the mold cavity without dismantling the mold. DMS is also showing Bolex P ball-guided ejector bushings. Here, the balls do not run aligned but at a slight angle, enlarging the contact area and enabling greater load capacity. Also, the company’s BZ hydraulic locking cylinders with robust cam-finger design are said to withstand heavy loads in a compact package for molds with side actions, slides or core pulls.

ALBA Enterprises is featuring its line of ejector couplers that automatically connect and disconnect on every cycle through the standard motions of the machine. This eliminates the need for specialized rods for each mold, while guaranteeing full return of the ejector plate. During a mold change, processors need only to move the machine knockout to the full back position. At that point, they are free from the mold and clear for removal of the tool.

SelfLube will showcase its trunnion lifter slides, which come in inch and metric sizes and are available with or without self-lubricating graphite.

Uddeholm is showcasing Uddeholm Mirrax ESR. The premium-grade stainless steel is especially suited for molding applications, according to the company. Mirrax ESR is described as a high-polish stainless tool steel with a combination of toughness, corrosion resistance, and uniform hardness across large cross sections.The company will also launch Corrax AM powder, a specially designed metal powder for additive manufacturing in plastics tooling applications.

Bales Metal Surface Solutions has a number of coatings and finishes to protect metals from wear, abrasion and corrosion. Its Diamond E.N. product reportedly provides the uniform corrosion resistance of electroless nickel with the added toughness of diamond particles for a hardness of 57 Rockwell C.

Progressive Components is introducing a monitoring and transmission platform that it says will advance the way the plastics industry monitors and maintains its tools. Progressive is pairing its tool-mounted CVe Monitor electronic mold-monitoring device to its CVe Live wireless device that relays data to the cloud-based CVe Live website.

New CVe Live features include a Press Management Module that allows for scheduling, tracking, monitoring, and filing of all preventive-maintenance actions. An expanded electronic filing cabinet with the ability to add non-CVe assets to the database and store related documents has been added.

Related Content

Where and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreTunnel Gates for Mold Designers, Part 1

Of all the gate types, tunnel gates are the most misunderstood. Here’s what you need to know to choose the best design for your application.

Read MoreWhy Shoulder Bolts Are Too Important to Ignore (Part 2)

Follow these tips and tricks for a better design.

Read MoreBest Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More