NPE

In the Zone: Materials Science Part 2

Explore the Materials Science Zone at NPE2024 and discover the chemistry behind the materials that best meet your needs.

Hannah Zelinski

Editorial Assistant

Crosshead Die for Elastomers Adjusts Easily

NPE2024: Mechanically actuated gum space adjustment requires only ordinary socket wrench.

Read More'Hybrid' Die Design Eliminates Weld Lines, Cuts Stagnation

NPE2024: Newest extrusion tool retains benefits of previous design and adds features to boost quality.

Read MoreRobotic Speed and Precision on Display

Sepro’s S5-25 Speed and 5X-25 robots work together in an interactive NPE2024 display to show the company’s range of automation capabilities.

Read MoreBlown Film Lines Are Fully Customized

Systems can be furnished for single- to nine-layer for barrier applications.

Read MoreInteractive Training for Injection, Extrusion and Other Processes

Paulson has four in-booth stations demonstrating its various training solutions.

Read MorePLASTICS Names McGwire Winner of 2024 William R. Carteaux Leadership Award

Member of PLASTICS for more than 40 years served on several committees and boards since 2005, including a stint as chairman.

Read MoreBASF Highlighting How They 'Make, Use and Recycle Future Solutions'

NPE 2024: On May 8, company chairman and CEO Michael Heinz gives keynote session, “Our Plastics Journey: The Road to a Sustainable Future.”

Lilli Manolis Sherman

Contributing Editor, Plastics Technology Magazine

In the Zone: Packaging Part 2

Check out the Packaging Zone at NPE2024 and explore the latest in both flexible and rigid packaging.

Read MoreCompletely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

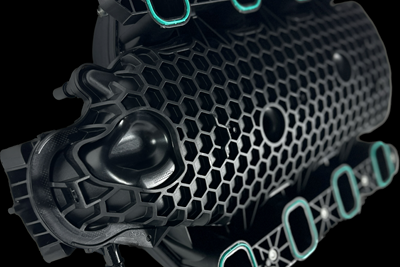

Read More8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE 2024.

Read MoreMachine Series Debuts for Chen Hsong

Chen Hsong has three injection molding machines in its booth, including 2-platen, hybrid and a next-generation line with improved platen and toggle design.

Read MoreAutomated Injection Molding Process Adjustments

Shibaura says its S-Concept represents an AI technology capable of making real-time process adjustments.

Read MoreEnhanced Temperature Controls for Hot Runners, Extrusion and Packaging

NPE2024: Athena introduces expanded hot-runner controller with up to 120 zones, plus updated panel-mount “universal” temperature/process control.

Read MoreDr. Walter Kaminsky: Pioneer of Catalysts Revolutionizing Polymer Production and Recycling

Dr. Walter Kaminsky’s pioneering research on metallocene catalysts at the University of Hamburg sparked a global revolution in plastics production. Inducted into the Plastics Hall of Fame in 2024, Kaminsky’s legacy continues to shape the polyolefin industry and plastic recycling technologies.

María Natalia Ortega Leyva

Directora Editorial, Plastics Technology México

BASF Chair to Keynote on Firm's Sustainability Path

Chair, CEO Heinz to discuss materials giant's sustainability journey.

Read MoreNext-Generation All-Electric and Vertical Injection Molding Machines

Sodick Plustech’s VR-G and MS-G2 Series both utilize the company’s proprietary V-Line technology, separating plasticizing and injection functions, and have upgraded displays, energy efficiency, response time and more.

Read MorePrecise Blender for Low-Throughput Molders

NPE2024: Gravimetric batch blender precisely delivers precise material blends from up to four ingredients at extremely low throughputs.

Read MoreRiverdale Global Showing Latest Innovations and New Satellite Location in Wisconsin

NPE 2024: Live demos of updated RGS controller are among the highlights at its Wisconsin facility that will house the ‘new’ color R&D lab.

Read MoreSmart Granulator Control Integrates Size-Reduction Systems, Enables Predictive and Knife Maintenance

NPE 2024: Conair’s New SG Control is available for its Viper Granulators

Read MoreArtificial Intelligence Manages Changing Conveying Conditions

NPE2024: Billed as an industry first, controls autonomously adjusts the conveying system in real-time to move material under optimal conditions.

Read MoreA Lifetime of Innovation in Plastics Machinery: Wolfgang Meyer

Wolfgang Meyer, a German mechanical engineer and industry leader whose contributions to plastics machinery have shaped the industry. Inducted into the Plastics Hall of Fame in 2024, Meyer’s work in injection molding, blow molding and sustainability has left an enduring legacy.

María Natalia Ortega Leyva

Directora Editorial, Plastics Technology México

Mini Control Offers Central Conveying for Small Plants, Work Cells

NPE2024: System supports vacuum conveying systems with up to three vacuum pumps and a maximum of up to 12 receivers.

Read MoreResin-Selection Station Conveys Material on Demand

NPE2024: Powerful, space- and labor-saving station makes the connections and conveys material automatically on command.

Read MoreAI Manages Resin Drying Airflows and Throughputs for Energy Savings

NPE2024: Optional feature automates the process of maintaining process-ready resins at perfect temperatures and varied throughputs, while preventing overdrying and realizing significant energy savings.

Read MoreResin Drying Hoppers Offer More Energy Efficiency, Durability and Cleanability

NPE2024: Drying hoppers provide improved energy efficiency and a durable textured metal exterior finish. Thicker insulation provides a cooler working environment, while polished stainless steel interiors resist material entrapment, and make cleanouts and changeovers faster.

Read MoreIn the Zone: Sustainability Hub

NPE2024: Experience the latest eco-friendly innovations in the plastics industry at the Sustainability Hub.

Read MoreiNOEX Celebrates Forty Years of Intelligent Measurement and Control Solutions at NPE2024

iNOEX’s expanded product portfolio highlights the importance of automated technology for the plastics extrusion industry.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)