NPE2018 Technology Focus: Hot Runners

Technology being tailored to specific needs.

Hot-runner technology is increasingly being tailored to the very specific requirements of the end markets and applications it will be serving. That fine tuning is very much on display at NPE2018. For example, Milacron’s Mold-Masters is introducing additions and enhancements to its Fusion-Series G2 hot-runner line, which is geared towards large-part production where high-end quality is required. Delivered completely pre-assembled and pre-plumbed, the line features field-replaceable heater bands for quick maintenance and shot sizes that range from less than 15 g to more than 3500 g.

New at NPE2018 are Mold-Masters F3000 and F8000 nozzles. The F3000 has a shot capacity of approximately 15 g and targets smaller under-hood parts, technical automotive components, and price-sensitive packaging and consumer goods. The F8000 increases the top shot capacity to 5000 g via runner diameters as large as 28 mm, with nozzle lengths that can exceed 1 meter. Target applications include bumper fascia, instrument panels, door panels and large white goods.

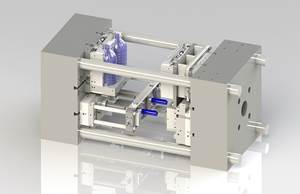

Mold-Masters is also introducing a second generation of its Melt-Cube side-gating hot runner. This system is said to provide vestige control, low pressure drop, and precise cavity-to-cavity rheological balance. Melt-Cube allows simultaneous direct side gating of up to eight cavities per Cube for high-cavitation molds. Tips are clamped by a single bolt in sets of two, greatly reducing assembly/disassembly times. Manifolds can be accessed from the parting line, and the system uses brazed heaters. Show attendees can experience assembly-time reduction first hand with a hands-on display of the Melt-Cube in the booth.

Mold-Masters Dura+ hot-runner system has been enhanced to include new Dura+ nozzles, full stainless-steel construction, and a highly polished runner finish. The line targets automotive lens applications. Mold-Masters will also display its TempMaster Series hot-runner controllers. Offering a compact cabinet and the ability to control 1 to more than 500 zones, the controllers apply Mold-Masters’ APS auto-tuning control algorithm.

Milacron will also highlight a new way to take advantage of its Kortec co-injection technology for products needing a three-layer barrier sandwich structure. Up to now, Milacron had provided turnkey systems consisting of a two-component injection machine, Kortec hot runner, and engineering support—including integration assistance, startup, and training. Now, molders who wish to use an existing press can choose the new Kortec Connect package, which is comprised of the Kortec hot runner, Mold-Masters E-Multi secondary injection unit as an add-on, and the same engineering support.

Synventive Molding Solutions is displaying the next generation of its eGate system of electronically controlled valve gates, which can control valve-pin position within 0.01 mm. The company will also feature its synflow pin control, which can be added to any of Synventive’s activeGate systems through an external hookup so that molders do not have to commit to a flow-control technology for the life of the tool.

Synflow’s third generation can stop the pin and hold it at any position mid-stroke, allowing individual flow control of each nozzle to balance family molds or fill complex geometries. Alternating opening profiles can be programmed, offering the ability to pre-fill cold runners or create differential packing within multi-gated parts.

NPE2018 is affording attendees four different opportunities to see HRSFlow’s FLEXflow electrically driven valve-gate system in action. In Wittmann Battenfeld’s booth, an automotive spoiler will be molded using a five-drop FLEXflow system. At Yizumi-HPM, a tool case will be molded using a three-drop FLEXflow system, in a process that also applies MuCell foaming and back injection. At KraussMaffei, a lightweight center-console armrest will be molded in cooperation with ProperTooling.

Günther Hot Runner Technology is featuring a new two-phase hot-runner stepper motor that can individually control up to 16 valve pins. The DPE motors come in four versions with 4, 8, 12 and 16 channels. All feature a 7-in. LCD touchscreen display that shows the stepper channels’ current position in color.

Thermoplay is launching a newly expanded small-nozzle series featuring the F Ø11 mini valve-gate nozzle. Designed for cosmetic, medical and packaging markets, the new nozzle’s larger inner diameter ranges from 3.5 to 4 mm, allowing increased melt flow. The minimum pitch for the F Ø11 valve-gate version is 17 mm but can be reduced to 13 mm with an open gate. Valve-gate actuation can be pneumatic or hydraulic, as well as individually or plate actuated. The pin, available in a cylindrical or conical option, is designed to minimize the witness mark on the part. Also from Thermoplay, the DL-1B nozzle has an extended tip for when the injection point is in critical locations that require a very small tip.

INCOE has expanded its DF (Direct Flow) nozzle line. The series now includes a slim DF 5 nozzle with 5-mm diam. and SBH (Slim Base Heater). Incoe notes that the “slim” design reduces the DF 5’s outer diameter by almost 25%, allowing nozzles with a large, 5-mm flow channel to be installed as close as 18 mm.

INCOE also has upgraded its GSCmini compact, low-cost, timer-based valve-gate sequencing controller. The new version can control either pneumatic or hydraulic valve actuation. Incoe recommends it for valve-gated applications that do not require sensors or linear transducer control, and for use in a tool room.

Männer has extended its Slimline nozzle range, launching a new product for valve gating in polyolefin applications with limited space. The small diameter—6.5 mm (0.256 in.)—of the Slimline caps and closure nozzle targets high-cavitation packaging applications.

Osco’s Jumbo valve-gate nozzle is designed for large shots of shear-sensitive resins. This custom single-drop nozzle delivers 28 lb of plastic. The Jumbo eliminates the need for a multi-drop manifold system along with the temperature and valve-gate controllers.

Hasco’s Vario Shot nozzle series will be completed at NPE2018 with the addition of the Type 50 nozzle size. A new screw-in Vario Shot will also be introduced. Hasco says this design allows for ready-to-mount systems.

Related Content

At NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read MoreAt NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More