On-Site: Custom Molder Pursues the Dream of Proprietary Products

“Every custom molder thinks he needs a proprietary product,” says John Currier, president and co-owner of the injection molding firm his father founded, Currier Plastics in upstate Auburn, N.Y.

“Every custom molder thinks he needs a proprietary product,” says John Currier, president and co-owner of the injection molding firm his father founded, Currier Plastics in upstate Auburn, N.Y. The logic behind the desire for proprietary products, he explains, is that they could help level out the cyclical ups and downs of the custom molding business. They could occupy unused machine capacity. And they would give the molder complete control over a product cycle, unlike the usual custom business.

But did he think Currier needed proprietary products? Not at first: “We’re custom molders. We don’t have that kind of sales and marketing organization—it would all be new to us. And we’re a small company—to do it right we’d have to invest time and effort.”

Just how new it would be, and how much investment it would take, Currier is beginning to find out. Because three years ago, his company began pursuing the custom molder’s dream, which is now starting to bear fruit.

OH, MY ACHING BACK

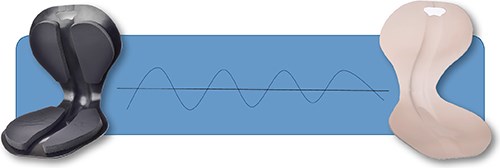

The PerfectSit is Currier Plastics’ first product that was conceived, designed, developed, tested, manufactured, and marketed entirely in-house. It’s described as a “structural orthotic training device meant to put you in an optimal sitting position.” It’s also described as “the world’s first one-piece, molded, integral lumbar support/coccyx relief unit.” It’s hot-runner molded of 1 lb of polypropylene, 1/8-in. thick, with all rounded edges, a cutout for a carrying handle, curves that force the user into an upright sitting position, and a channel in the bottom that relieves pressure on the base of the spine (coccyx) and prevents heat buildup as well. Self-adhesive polyurethane pads are supplied for optional attachment to the base and back of the device. (They’re detachable and re-attachable in positions to suit the individual user.)

The PerfectSit is quite a departure from Currier’s usual line of work. The firm (currierplastics.com) was started by John Currier’s father, Raymond, in 1982. In recent years, it has evolved from a general-purpose custom injection molder serving a wide range of industries toward a focus on packaging—tubs, caps, and closures—though it still has a dedicated bank of machines molding hundreds of millions of coaxial cable connectors annually. Currier has also added extrusion blow and injection stretch-blow molding of bottles. Today, it’s a $22-million/yr company with 100 employees, 24 injection presses, and 15 blow molders in a 65,000-ft2 plant.

“Custom molders are a dime a dozen—it’s what you do differently that counts,” says Gary Kieffer, vp of new product development, co-owner, and one of the firm’s original four employees. “What’s different about us is that we can mold both the container and the closure. And we do product design, which our customers increasingly appreciate.” In a way, the PerfectSit is a return to the company’s roots. “Ray Currier’s expertise was in design,” Kieffer points out.

Massimo (Max) Leone, vp of business development, joined Currier six years ago, coming from a major electronics firm. He was familiar with proprietary technologies and started immediately looking in that direction for Currier Plastics. The answer came to him on long business trips in his car, which left his back sore. He began to research available orthotic products that could minimize discomfort from hours of sitting. “There are hundreds of products out there—stamped, thermoformed, single-piece, multi-piece, some with lots of padding and cloth covers.” He also did library and online research in medical and physical-therapy journals. And he consulted with local urologists, physical therapists, and chiropractors.

“It’s a huge market,” Leone concluded. “Up to 80% of Americans experience some form of back pain at some point in their lives. Each year, approximately 15% of all adults are treated for such problems. It’s estimated that in 2008, $17 billion was spent on back pain, and that will grow to $23 billion by 2018. It’s because our bodies weren’t made for so much sitting, and we spend about a third of our time in that position.”

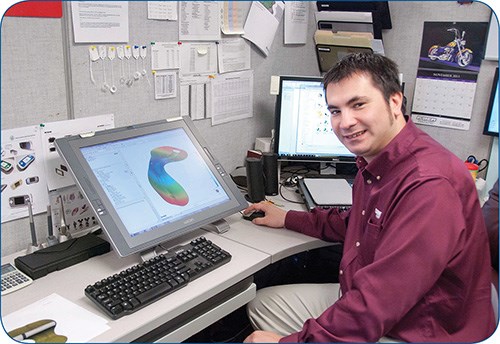

In 2008, Leone came up with a concept. He cut and folded a cardboard model of a right-angled, seat-shaped precursor to the PerfectSit. It was uniquely simple and multi-functional. He showed it to his colleagues and assembled a development team of six people from Currier’s design, engineering, and marketing departments—including Kieffer, Leone, and design engineer Larry Jedik. They had to find a way to pursue this idea (they called it “Project X”) without cutting into their primary duties. So they met on Wednesdays for lunchtime design-review meetings. CAD drawings were projected onto a whiteboard and revisions drawn over the image on the board. There were lots of weekend hours expended, as well.

Leone purchased some existing products to evaluate competing designs. Some were large and bulky. Some were quite expensive—as much as $200 to $300. Some addressed lumbar support, some coccyx relief, and some did both.

Kieffer’s first step beyond Leone’s folded cardboard concept model was to mold a model of the contours of a sitting person’s backside. In his kitchen at home, he poured some plaster into a box, covered it with a sheet of plastic, and sat on it. From there, the progression was toward plastic prototypes. “We analyzed the options—CNC machined prototype molds, thermoformed parts, or 3D digital printing,” Kieffer said. “Local tool shops weren’t interested in the prototype molds, so we went to digital printing through an outside service bureau.” It was the company’s first experience with rapid-prototyping technology for a part this size. Now, a digital printer is in the budget for next year.

The design evolved through a series of 10 ABS digitally printed prototypes. Employees tried them out for comfort, and mechanical properties were evaluated on a large Shimadzu tensile-test frame in the company’s well equipped lab. Prototypes were tested at room temperature and—to simulate outdoor use in a car—they were buried in snow to chill them until just before testing. Using a fixture that held the prototype by the back, the machine pushed down on the horizontal seat section. The ABS prototypes all broke at the right-angle bend area. “That helped us to engineer the final design,” Kieffer says.

The team considered polycarbonate and PP as alternate materials. PC was engineering “overkill” and expensive, notes Kieffer, but PP turned out just right. In the tensile torture test, 200 lb of force are applied, causing the PP parts to bend almost 90° without damage and then return to their original shape. Best of all, notes Kieffer, “We can use our house grade of PP that we already buy in large volume for caps and closures.”

The team also investigated padding. Two-shot molding was considered but rejected because the available TPE materials did not offer the comfort profile needed. So open- and closed-cell PUR foams were investigated for outside purchase. The final design was given to a panel of 20 outsiders to test for a week, and they were then surveyed about their reactions.

DESIGN FOR MANUFACTURING

Besides digital printing, Project X exposed Currier’s team to other new technologies. One was laser scanning with a compact device recently installed to design containers. It converted Kieffer’s plaster seat model into data points to create a CAD surface model—a valuable step, since the design has over three dozen radii and hardly a single straight line.

Another new experience was flow simulation. During this project, Currier purchased Autodesk’s Moldflow Part Adviser. It predicted that material flow fronts would merge around the handle shutoff area, a critical aesthetic location. The software also predicted that, with rounded edges and proper venting, a strong knit line would form without compromising product integrity. That prediction was confirmed in the testing lab.

Throughout the team’s meetings, Kieffer harped on design for manufacturability. “I kept reminding them: ‘Clamp tonnage! We don’t have a big enough machine!” At 1 lb and around 225 sq in., the PerfectSit is larger than any other part Currier currently produces. The firm had presses only up to 300 tons when the project started, but then purchased machines up to 500 tons to handle higher-productivity cap molds with up to 64 cavities. Kieffer also was concerned about parting lines, which had to be located so as to avoid any sharp edges that would make the product uncomfortable to handle. Also, the part had to demold without any unsightly ejector marks.

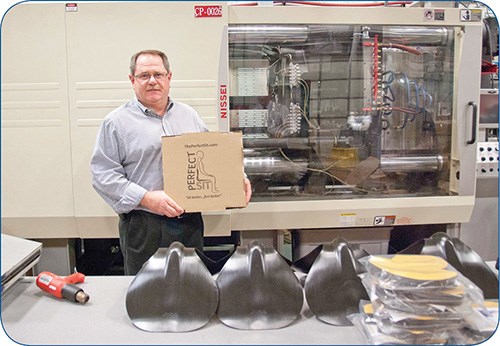

The part turned out to be a “no-brainer to mold,” according to Kieffer, despite a surprise or two. “Initially, we wanted the part to stay on the mold core and be demolded by hand with no ejectors. But the part wanted to stay in the cavity, which worked out just fine.” The parts run in either a 400-ton or 500-ton press with a single-cavity mold.

Currier learned that parts needed some cooling time outside the mold so they wouldn’t distort or scuff. So the operator lays several parts on a table beside the press, where a stream of deionized air prevents picking up dust, and boxes them after cooling for three or four mold cycles. The operator erects the unusual triangular box (handy and eye-catching for retail display) during the molding cycle.

The current cycle is under 60 sec, but Kieffer says it can go lower in the future by using a robot, an aluminum mold with better heat transfer, and specially engineered cooling baffles that direct the water in a spiral turbulent flow within the gun-drilled channels.

GETTING MANAGEMENT BUY-IN

About five months into what has become a nearly three-year project, the Project X team presented their progress to Currier’s management to get a formal go-ahead and a budget for prototypes and other development costs. CFO Mike Cartner (also a co-owner) says, “My job is ordinarily dry—working the numbers, coming up with cash, telling people ‘No.’ But there was a sense of excitement about developing our first proprietary project: ‘It’s all ours!’ But could we pull this all together to make it work? We’re used to the manufacturing stuff, but I worried about the marketing. And I worried about what it was going to cost.”

John Currier said what sold him was “Max’s passion and the completeness of his proposal. This was not a harebrained scheme—he really did his homework.” In fact, Leone devised a list of 12 points that a potential product had to satisfy to be suitable for Currier Plastics (see table). The PerfectSit met them all.

It was not all smooth going, Currier concedes: “There were a lot of obstacles. We had some pretty frank and brutal discussions around this table. A lot of times we said, ‘Nah, it’s not going to make it.’’ The growing number and cost of prototypes was an issue. “The development team would say, ‘We need one more prototype,’ and I would say, ‘Do you, really?’ I tried to be the Doubting Thomas. But I didn’t want to cheap out, either. I figured, now that we’re so far into this, we don’t want to quit now, do we? A key factor is that every project like this needs a champion, like Max, that keeps driving it forward.”

SHOULD YOU MAKE THE LEAP?

What lessons can be learned by other custom molders that might wish to follow their own dream of proprietary products? Leone advises asking yourself four questions:

First, do you have the right personnel to accomplish this? One of Leone’s 12 points is that a proprietary product should utilize a company’s core competencies. “The PerfectSit made sense because it used all our talents—design, process engineering, and quality testing.” Having the right people also means dedication—all those lunch hours and weekends that the development team devoted to this project.

Second, Leone asks, do you have the right corporate structure for such a project? Custom molders are not usually organized to develop new products. Leone created a Business Development Dept. at Currier Plastics that brings together engineering, sales, and marketing people, whose departments are often isolated from one another.

“There’s a strain on your resources when you pursue a new business model,” he says. “You need to ask, ‘Do we go outside our own resource group?’ There was understandable concern initially from some departments within the company. They were concerned that we had always been a business-to-business manufacturer. Now we would have to handle shipping to individual consumers. We might have to outsource that.”

Currier Plastics was fortunate in bringing in Leone with his experience in marketing—which is not so common at smaller custom molders. “When you have a new product of your own to market, you have to know how to get the word out, and you need people to do it,” Leone says. He hired a new temporary assistant to mail out 5000 PerfectSit packages to journalists, media people, and other “opinion leaders.” (The product is also available for $29.95 at theperfectsit.com.)

Other new skills had to be acquired along the way. “Patents were new to us—one is pending on the PerfectSit. You need a good attorney for that. We also had to learn about trademarking a name, a logo, and a tag line, ‘Sit better … feel better.’”

Leone even set up a new legal entity, Aurora Design LLC, to be the legal parent of the PerfectSit. He did this initially for product liability reasons, but he adds that “the next step is to develop other products for ourselves—and for other companies. We have built a pretty good template for future product development.”

Budgeting for product development is another skill to learn. The PerfecSit will cost $110,000 to $150,000 to bring to market, including personnel time, prototyping, tooling, and marketing. “Don’t underestimate the marketing costs,” warns CFO Carter. “We could easily have spent three times the engineering costs on marketing, but we didn’t.”

Third, and especially important, Leone asks, “Is upper management involved? This kind of project needs support. It will hit a wall occasionally and needs someone to nod and say, ‘Keep going.’”

Leone’s fourth question is, do you have the right product? “Are you going to create something meaningful that fills a need? To answer that takes research. Don’t do it from the seat of your pants. You have to really know the market you want to enter. For example, we asked, how many people have back problems? What’s already available for them? We consulted the literature and local experts. We tried to throw as much science at it as we could.”

Related Content

Pregis Performance Flexibles: In the ‘Wow’ Business

Pregis went big and bold with investment in a brand-new, state-of-the-art plant and spent big on expanding an existing facility. High-tech lines, well-known leadership and a commitment to sustainability are bringing the “wow” factor to blown film.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreRead Next

On-Site: This Currier Delivers

“We love to tell our story.” That’s one way Mike Cartner, CFO of Currier Plastics, defines what separates this family-owned custom processor from its competitors.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More.png;maxWidth=970;quality=90)