Packaging & Automotive Top the News

Food and consumer packaging was the focus of new developments in polyolefins and styrenics, while automotive was the main target for new engineering materials.

Food and consumer packaging was the focus of new developments in polyolefins and styrenics, while automotive was the main target for new engineering materials. There were plenty of novelties in both groups: Packaging entries included metallocene HDPEs for bottles and film and several brand-new types of polypropylene. On the automotive side, suppliers showed off new on-line paintable automotive alloys, fuel-resistant nylons, and a host of other ABS, PC, nylon, and PBT materials for interiors, exteriors, and under the hood. There was also plenty of engineering-materials news to interest makers of electrical parts, appliances, business machines, and consumer goods.

Metallocene HDPE bows in

K 2001 saw the debut of the first metallocene HDPE commercialized in Europe or the U.S. (Asahi Chemical of Japan came out with one in 1999.) Aimed at small bottles for cosmetics and personal-care products, Finacene BM359 SG from AtoFina of France has unusually high gloss, reportedly comparable to that of PP, plus greater flexibility than other glossy HDPEs. This monomodal hexene copolymer boasts good ESCR. It has a relatively low density of 0.935 g/cc and MI of 0.9. It can be used by itself to make glossy squeeze bottles, or it can be coextruded with a stiffer HDPE, AtoFina's recently introduced Finathene BM593 HDPE, a bimodal hexene copolymer (0. 959 g/cc, 0.27 MI) that also has good ESCR. This combination is said to extrude easily at high rates without melt fracture.

AtoFina also introduced a glossy metallocene HDPE for film, Finacene M 3410 EP. Aimed at freezer bags, premium bags, and high-clarity packaging for hygiene products, the resin is said to offer a balance of stiffness and strength that permits downgauging and handles well in packaging machinery. AtoFina spokesmen say it's likely AtoFina will bring its mHDPE technology to the U.S.

Also new is AtoFina's Finathene 56020 S HDPE for jerry cans and medium-size drums offering high melt strength, excellent processability, and resistance to stress cracking by acids and pesticides.

MDPE for hot-water pipe

A new MDPE from Dow Plastics, Midland, Mich., is said to close the gap between standard PE and crosslinked PE (XLPE) in hot-water pipe. New Dowlex 2388 (0.935 g/cc, 0.85 MI) is aimed at in-floor heating, radiator connections, snow-melt systems, heat exchangers, solar panels, and domestic hot/cold drinking water systems. Up to now, Dowlex 2344E (0.933 g/cc, 0.7 MI) was the only non-crosslinked PE resin approved by the Plastic Pipe Institute (PPI) for pressure pipe use at 180 F. The new grade reportedly provides even higher long-term strength at elevated temperature—thus it can compete with XLPE in a broader range of applications. Processors can save money by eliminating the crosslinking step, running higher line speeds, and/or downgauging. Extremely good processability allows pipe to run even faster than with Dowlex 2344E and produces smoother surfaces. Another possible application is composite pipe of PE/aluminum/PE. Price is comparable to Dowlex 2344E.

New types of PP

A new polypropylene reactor process developed by Basell Polyolefins (U.S. office in Wilmington, Del.) promises to yield more uniform polymers with higher crystallinity and stiffness while retaining toughness and processability. Basell's Multizone Circulating Reactor (MZCR) is a gas-phase process that produces bimodal PP in a single reactor. Each PP granule is circulated repeatedly around the reactor loop, building up alternating layers (like an onion) of resins with different molecular weight and/or composition, which are polymerized in different zones of the reactor. The MZCR is said to produce a more homogeneous mix of the different molecular-weight fractions than is possible with a multi-reactor or extrusion compounding process. The result is fewer gels and reduced energy to extrude and pelletize the material.

Basell is converting a 352-million-lb/yr Spheripol plant in Brindisi, Italy, to MZCR. It will be on stream in May. Although starting with homopolymer production, Basell will later use MZCR for copolymers. Basell researchers believe the process could produce random copolymers with an improved balance of toughness and clarity and much lower ductile/brittle transition temperature.

In the past year, Basell also came out with two new classes of PP copolymers, trade named Clyrell, that are made with its Catalloy process. Clyrell heterophasic (impact) copolymers for injection molding boast unprecedented combinations of clarity, gloss, and toughness. They show haze values of 20-22%, plus toughness at –30 to –40 F and resistance to stress whitening. Clear ice-cream containers and paint cans are two of the first applications. Basell is developing high-flow grades that retain the impact/stiffness balance of existing Clyrell resins.

Clyrell random copolymers for cast film and fibers are said to have unusually low seal-initiation temperatures (252-257 F) and half the usual level of hexane extractables. Likely uses are cook-in-bag packaging and sterilizable medical packaging. Clyrell reportedly makes cast film that can be metalized and has good deadfold properties, suitable for twist wrap.

Basell is also expanding the range of its Metocene metallocene PPs. Up to now it has offered homopolymers with unusual combinations of stiffness, high clarity, and low warpage for injection molding, plus fiber grades with excellent orientability. Newer Metocene impact copolymer molding grades combine good transparency with low-temperature toughness (down to –4 F) and reportedly unprecedented organoleptic properties. Basell is also sampling a random copolymer for molding (Metocene X70293) with improved toughness and "unheard-of transparency" for a PP resin.

On-line paintable alloy

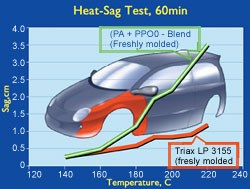

A nylon/ABS alloy from Bayer (U.S. office in Pittsburgh) is the newest contender for auto body panels that can be painted on-line. New Triax LP 3155 thus challenges Noryl GTX nylon/PPO alloys from GE Plastics. Bayer says the Triax grade withstands 20-min exposure at 170 to 200 C (338 to 392 F) for baking conductive primers. Bayer says it has an HDT of 194 C (381 F) at 264 psi vs. 180 C (356 F) for Noryl GTX. This reportedly translates into more than 100% better performance in practical heat-sag tests (see graph). Bayer also claims the new Triax grade has 14% lower CLTE than GTX, 27% lower shrinkage, and 78% higher stiffness. Good ductility is also reported.

Meanwhile, GE Plastics Europe in the Netherlands (U.S. headquarters is in Pittsfield, Mass.) brought out last July a more heat-resistant version of its conductive Noryl GTX for on-line painting. Noryl GTX 975 is used on the Jaguar gas-tank flap.

At the show, GEP Europe introduced two more automotive materials. One is Cycolac DL100 ABS, a reduced-odor grade that meets Volkswagen's very stringent volatile emissions limit of 50 ppm.

GE has started sampling a new line of Cytra ABS/PBT alloys designed to give a uniform low-gloss appearance to auto interior parts without painting. Cytra is also designed to give good impact strength, whereas low-gloss ABS tends to suffer in this regard.

More automotive resins

A novel PC/ABS from BASF (U.S. office in Mt. Olive, N.J.) chemically anchors the twin building blocks to achieve a superior low-matte finish in injection molded auto-interior parts for consoles, steering columns, and radio covers. Terblend N's morphology and flow properties are tailored to better duplicate the microstructure of mold wall surfaces that impart low-matte finishes.

DSM Engineering Plastics (Evansville, Ind.) introduced new-generation PC/ABS blends that exploit continuous mass-polymerized ABS as a base material for automotive use. This ABS class, not previously used by DSM, tends to be "cleaner" (causes less mold deposit) and have more consistent color than standard PC/ABS. DSM also claims improved thermal stability and ESCR for the new Xantar C grades.

Bayer tailored its new Bayblend KU2-1446 PC/ABS for high-impact auto-interior parts like knee bolsters that must absorb energy in crashes, even at low temperatures. The material will appear on 2002-model Mercedes-Benz and BMW cars.

Another new Bayblend grade, KU2-3030, is a flame-retardant compound (UL 94V-0 at 1.5 mm) that contains no halogen or heavy metals. It is designed to replace rigid PVC in cable conduits, where German standards forbid halogens. It reportedly offers no "juicing," low-corrosion combustion gases, and an HDT of 125 C (257 F)—higher than for established cable-conduit materials. The compound is optimized for tube and sheet extrusion and for thermoforming. Uses include electronic installations, construction, aircraft, and public transportation.

A third new blend from Bayer is Pocan DP2-7655, a mineral-reinforced PC/PET aimed at exterior car trunk panels, door sills, and fenders. Compared with currently used PC/PBT blends, the new grade has lower CLTE for achieving close to zero gap between subassemblies. It also is said to permit thinner walls and to provide greater dimensional stability.

Rhodia of Italy and Cranbury, N.J., introduced 25% and 30% glass-filled Technyl nylon 66 grades designed to meet new requirements for automotive cooling systems, including radiator tanks, heat exchangers, pumps, and thermostats. They are said to offer excellent glycol resistance and can handle 130 C continuous and 160 C peak temperatures. The 30%-glass grade shows no loss of impact strength at elevated temperatures, while standard nylon 66 suffers about a 50% drop.

Nylon 6 auto intake manifolds also face escalating thermal requirements, so BASF has come out with a 30%-glass, black Ultramid grade offering improved toughness, processability, and hydrolysis resistance. It can be used in either vibration-welded or fusible-core-molded designs.

Meanwhile, Bayer's new branched nylon 6, Durethan BKU 330, is designed for better welding (vibration or laser) of intake manifolds. It's available in a laser-transparent black.

Another new branched nylon, this one a 66 grade, is Bayer's Durethan KU2-2240/25. It has 25% glass and increased melt strength for blow molding automotive tubing and ducts. Besides good parison "hang" capability without stretching, the material reportedly shows better impact retention upon exposure to glycol/water mixtures.

For oil sensors and other automotive electronics, BASF brought out two laser-transparent, intensely black, 30%-glass compounds suitable for laser welding. Ultramid A3WG6 LT nylon 66 and Ultradur B4300G6 LT PBT boast higher laser transparency than competing materials, thereby increasing speed and reliability of joining.

Fuel-resistant nylons

Suppliers announced new nylon 12 systems tailored for automotive fuel systems. Degussa High Performance Polymers (formerly Creanova) has a special Vestamid nylon 12 developed for the return lines of common-rail diesel injection systems and for fuel lines located near the engine. It boasts improved fuel resistance at temperatures up to 125 C (257 F). Degussa's U.S. office is in Parsippany, N.J.

Ube of Japan (Ube America, Inc., N.Y.C.) developed Ubesta 3020 X 25 L nylon 12 for extrusion coating of metal fuel or brake tubes. This special grade is designed for consistent extrusion of thin layers without gels. It is said to be simpler to apply than previous PVF coatings and also provides better resistance to chipping and impact.

In addition, Ube came out with nylon 5034 UC 2, a nano-clay composite of nylon 6/66 copolymer for use in high-barrier fuel tubes. It could be coextruded with inner and outer surface layers of nylon 6 and 12, plus an adhesive.

Ube also has a new type of Ubesta nylon 12 for natural-gas pipe sockets. It offers four-fold improved bond strength when solvent welded to the nylon 12 pipe, Ube says. The company recommends nylon 12 as an alternative to HDPE gas pipe because its higher burst strength permits higher operating pressures or up to 40% weight savings through reduced wall thickness for the same pressure rating. Uniquely high molecular weight of Ubesta is said to permit easy, stable extrusion of even large-diameter pipe.

Among unreinforced engineering thermoplastics for automotive uses were a pair of new Orgalloy nylon alloys from AtoFina Chemicals, Inc., Philadelphia. One is formulated for coextrusion as a thin scratch-resistant capstock on PP interior trim. It is said to give a matte finish and reduced moisture sensitivity. Another new grade, Orgalloy LT 4060 ES, is for blow molding under-hood parts. It reportedly provides temperature resistance to 150 C and excellent chemical resistance. Also, new Orgalloy LT 5050 T6L is aimed at high-pressure flexible hose for air conditioners. The plasticizer-free product offers excellent chemical barrier and good wear resistance.

More engineering compounds

Dow Plastics, Midland, Mich., exploits its continuous mass ABS in new Emerge 7100 and 7500 PC/ABS for thin-wall business-machine and other housings. Dow's offerings emphasize improved cost, esthetics, and environmental benefits. Emerge 7100 is for use with color concentrates; it reportedly exhibits superior base color and lot-to-lot consistency. Grade 7500 is a non-halogen, UL 94V-0 grade for copier and printer housings.

Few details were provided on a developmental neat PC resin from Bayer, Makrolon DPI-1848, said to give better low-temperature impact, HDT, and ESCR than standard PC.

DSM unveiled upgraded FR glass-reinforced nylon 6 and PBT offerings for switch gears, circuit breakers, motor starters, and other electronics. Trade named "Segregate," they are rated UL 94V-0 at 0.75 to 1.6 mm but do not contain halogen or red phosphorus. Optimized glass-fiber length is said to provide extraordinary stiffness and toughness. For instance, Aukulon K-X6399 nylon 6 with 25% long glass offers 1.38 million psi tensile modulus and 17 ft/lb-in. notched Izod impact.

GE Plastics, Pittsfield, Mass., showed new Valox V9760NH 30%-glass PBT for electrical parts in appliances, plus fuse holders, circuit breakers, and connectors. It contains no halogen or red phosphorus.

Three new grades of Ixef polyarylamide (MXD6 nylon) come from Solvay Advanced Polymers (U.S. office in Alpharetta, Ga.). They're suited to a range of applications, from automotive to business machines, appliances, and electronics:

- Ixef 1028/9208 is a black, laser-printable compound with 50% glass.

- Ixef 1622 also has 50% glass, plus rubber modifier for improved impact resistance (2.15 ft-lb/in. notched Izod).

- Ixef 2011 is a glossy, 41% mineral-filled grade with isotropic shrinkage and increased HDT (365 F @ 264 psi) for use in headlamp reflectors.

New from Degussa High Performance Polymers is the Trogamid CX family of microcrystalline, highly transparent nylons. They boast a combination of high chemical and uv resistance, low water absorption, high impact resistance—even at low temperatures—excellent abrasion and scratch resistance, and easy processing with low, isotropic shrinkage. Three grades with different viscosities are available for injection molding and extrusion. HDTs are 221-230 F @ 264 psi. Initial use is in sport glasses and sunglasses.

EMS-Grivory, Sumter, S.C., also launched a clear but tough amorphous nylon 12 family, Grilamid TR 90, offered in unmodified and uv-stabilized versions.

RTP Co., Winona, Minn., introduced highly wear-resistant materials using 0.1% to 1% levels of perfluoropolyether (PFPE) as a lubricant. By improving the method of dispersing PFPE in the matrix, RTP is able to significantly lower cost. Other benefits are reduced plate-out, better processability, and reduced marring, scratching, and squeaking of part surfaces. PFPE-lubricated grades include nylon 66 and acetal.

Dyneon, Oakdale, Minn., unveiled a new fluoropolymer for communication wire and cable. PFA X6525 has a maximum service temperature of 260 C (500 F) vs. 205 C (401 F) for Dyneon's existing FEP 6322 grade.

Related Content

Recycled Material Prices Show Stability Heading into 2023

After summer's steep drop, most prices leveled off in the second half.

Read MorePolyethylene Fundamentals – Part 4: Failed HDPE Case Study

Injection molders of small fuel tanks learned the hard way that a very small difference in density — 0.6% — could make a large difference in PE stress-crack resistance.

Read MoreResin Prices Still Dropping

This downward trajectory is expected to continue, primarily due to slowed demand, lower feedstock costs and adequate-to-ample supplies.

Read MorePrices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.png;maxWidth=300;quality=90)