Plastics Welding: Laser and Infrared Systems Expand Capabilities

A breakthrough in laser welding of three-dimensional parts that eliminates traditional clamping systems was among several innovations in welding and joining highlighted at two recent shows—last month’s Plastics USA in Chicago and this month’s K 2004 in Dusseldorf, Germany.

A breakthrough in laser welding of three-dimensional parts that eliminates traditional clamping systems was among several innovations in welding and joining highlighted at two recent shows—last month’s Plastics USA in Chicago and this month’s K 2004 in Dusseldorf, Germany. Other developments (including some not exhibited at these shows) include greater use of servo drives in laser, hot-plate, and vibration welding systems, a PC-based control system that manages up to four ultrasonic welders, and the first optical-transmission instrument to measure the laser weldability of plastic parts.

A first for 3D

Leister Process Technologies of Switzerland claims that its Globo or sphere welding system is the first to weld 3D parts without the need for clamping systems. The laser follows a contour in a sequential welding process. The laser is focused on the joining plane by means of an air bearing, a frictionless, rotating glass sphere. The glass lens both focuses the laser energy and acts as a tool to provide mechanical pressure perpendicular to each point on the joining plane.

Previously, laser welding required that the two plastics parts had to be clamped together, usually with glass. Now, the laser head serves as the clamping medium. “With the integrated mechanical clamping device in the laser head, we clamp just as the head moves over the part,” says Marcel Pironato, director of marketing.

The Globo welding system not only opens up opportunities in 3D parts but also removes limits on parts size. Large, flat parts that previously required significant pressure to weld can be joined with the Globo system, says Jerome Zybko, general manager of Leister USA. And large TV components, which required costly 5-ft clamping fixtures, now can also be welded clamp-free.

Among the most promising applications are automotive headlight assemblies. The Globo welding process would replace two-part epoxy adhesive systems, which require cure-time delays, and vibration welding, which generates particulates.Another laser welding supplier, LaserQuipment, is touting the joining of 3D parts with a hybrid laser process that combines the cost-effectiveness of conventional infrared welding systems with the efficiency of laser welding. IR light emitted by halogen lamps is focused at the same point as a laser beam on the weld seam. This evenly distributes heating of the weld plane, yielding faster cycles and requiring less laser power than conventional laser contour welding, the company claims. Feed rates in welding 1.5-mm-thick PP specimen plates are twice as fast as conventional welders with the same laser power.

LaserQuipment is also introducing the TMG Vario, one of the first devices to measure optical transmission of plastics in order to determine their laser weldability.

Gentex Corp. re-cently announced that its laser-welding coatings meet biocompatibility requirements of USP Class VI. That means that medical devices welded with Clearweld coatings should obtain FDA approval, says Gentex.

Clearweld coatings are used as a replacement for carbon to convert laser energy into heat. The coatings are applied at the joint interface or compounded into resins. These light-absorbing materials provide color flexibility in a range of thermoplastics.

BASF is introducing two near-infrared (NIR) absorbers for laser-transmission welding. Lumogen IR 788 and 765 are highly transparent additives with low color, so clear plastics can be made to absorb laser energy for welding.

Better IR welding

For infrared welding, Heraeus Noblelight will introduce the first carbon-based infrared emitters, said to provide rapid response and high heat output. Carbon emitters provide three to five times the heat output of halogen lamps and last four to five times longer, the company claims. Carbon emitters generate 200 watts/in. compared with 30 to 40 w/in. for other medium-wave heat sources such as Nichrome and ceramic heaters. In high-output systems, carbon emitters offer more control and are more efficient and less costly. Carbon emitters also eliminate signal noise and the need for special fusing to handle high in-rush current. They provide a peak wavelength that is equal to the absorption spectrum of most plastics, according to Heraeus.

The latest development in the P-Wave through-transmission infrared (TTIR) welding process from Kubota Research Associates is the P-Wave Welding Gasket. This injection moldable material contains a small quantity of IR-absorbing additive dispersed in a thermoplastic or TPE. The custom-formed gasket is placed between the two parts to be welded and pressure is applied to hold the gasket in place. Focused IR energy passes through the transparent top part and heats up the gasket, which melts and flows to fill the bond line. This approach facilitates welding 3D shapes and eliminates the need for a smooth and precise fit between the components to be joined.

Servos boost control

Branson is adding a servo lift drive to its newest laser welding system, the L-368 Fai. Like other welding equipment makers, Branson added the servo drive for increased positioning control and repeatability. The system also incorporates Branson’s latest laser Gen 3 closed-loop controller. The machine is similar to the company’s IRAM-300 model. Branson chose a gear cylinder instead of a hydraulic table drive to reduce dirt and noise as well as increase accuracy and control.

Branson’s new vibration welder, M-624 Hi RS, has a servo drive for better position control plus infrared preheating capability for increased weld strength and tighter tolerance of the welded assembly. IR preheating of the joint plane almost eliminates particulates, and active braking of the vibration head increases weld strength significantly, claims Branson.

Forward Technology has expanded its hot-plate welding line with a large servo-controlled unit. The company is responding to the industry’s growing appetite for servo systems that provide a higher level of control and repeatability and faster cycle times.

Forward, which already produces small servo-controlled hot-plate welders, says the new VS-1445 is one of the largest servo-controlled units in the industry, with a maximum part size of 14 x 45 in. Dave Kralovetz, v.p. of sales, says the new product offers the “ultimate” in control of hot-plate welding.

With servo controls,tooling hard stops are eliminated, allowing maximum adjustability in melt and weld depth by changing control settings. Mechanical changes are no longer required. The melt and weld phases are tightly controlled by melting to a target collapse distance or absolute distance, says Forward. The unit is targeted for automotive, medical, and appliance applications.

Branson has unveiled a PC-based control system that manages up to four ultrasonic welders. Previous control systems could only handle one welder at a time. The 2000mc Net includes a graphical user interface and data-management capability. The company is developing a control unit to manage eight welders.

Branson also is introducing an ultrasonic power supply/controller that has multiple interfaces (RS232, USB, Profibus) for integration into special machines or production lines. The Professional Compact has onboard intelligence that enables the user to capture information, network, and troubleshoot.

More rigid construction

In ultrasonic welding, Sonics & Materials is introducing a 20-kHz, pneumatically actuated press that is said to be more rigid than competing models for minimized deflection and improved precision and performance. The 2055 press features a newly designed base casting with integrated hub, precision-machined components, increased throat depth, and increased column diameter and wall thickness. This construction reduces the potential for deflection by up to 30%, says the company.

The ultrasonic press also features a high-efficiency snap-in converter that rotates 360° to simplify radial horn alignment, while a quick-release, threaded positive stop provides fine adjustment and limits the downward travel of the horn.

Dukane Corp. is unveiling two new vibration welders that reportedly handle a wider range of tooling with high reliability and shorter weld times. The mid-size VWB3500 (965 x 455 mm) and the larger model VWB3700 (1320 x 610 mm) are aimed at glass-filled resins and engineering plastics. Dukane says the electromagnetic vibration heads are extremely durable and require no lubrication because they have no bearing surfaces. Shorter weld times are achieved by optimizing the heads to accommodate heavy tooling at high frequencies.

The vibration welders feature rigid construction—including a four-rail lift-slide assembly and a lift table framed with rectangular steel tubes—which allows efficient transmission of vibration to the parts. Unitized construction makes the welders easier to install and move compared with units having separate sound enclosures that require on-site assembly. Tom Kirkland, Dukane business unit manager, says the machines are priced in the low- to mid-range level but include upscale features such as convenience outlets, interior work light, and a pre-wired valve manifold block.

Advanced heat staking

Sonitek has launched the Spectrum Slim-Line series of heat-staking systems. A compact and rigid actuator is suited to benchtop manual operations as well as semi-automated and fully automated systems. New features in the Spectrum line of thrusters include integrated hydraulic speed controls, post-cooling manifolds, built-in pneumatic controls, and micro-adjustable positive stops.

The Spectrum actuators allow staking by depth or force and include additional operational modes for preheating, tamping, and secondary cold staking. More demanding end users also have the option of total SPC control.

Related Content

Sustainable Materials is Focus of Thermoforming Exhibits at K 2022

Thermoforming equipment makers including WM, Kiefel, and OMV will showcase processing of recyclable and biobased materials.

Read MoreAdvanced Hardcoat Technologies for Automotive

Momentive’s SilFort technology geared to auto exterior applications.

Read MoreSD Polymers: 'One-Stop Solution for Mechanical Recycling'

‘Passionate’ recycler invests in people and technology to meet commitment to innovative, sustainable solutions for its processor customers.

Read MorePlastics Technology’s Most-Viewed Articles from 2022

Tips, new technologies, resin pricing, best practices and more piqued reader interest at Plastics Technology in 2022.

Read MoreRead Next

New Approach to IR Welding Bonds More Engineering Plastics

Kubota Research Associates (KRA), a U.S.-based research and development firm, has introduced an advanced method for through-transmission infrared (TTIR) welding of sensitive plastic parts.

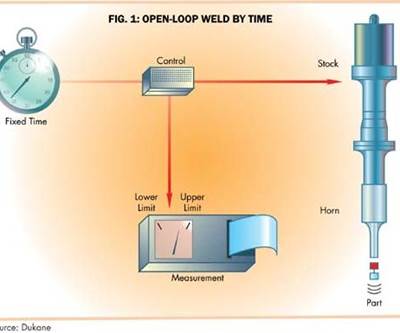

Read MoreHow to Use Those Fancy Ultrasonic Welding Controls

You know how to set a timer, but newer ultrasonic welders also offer control by energy, collapse distance, and absolute distance. Do you know when and how to exploit these options to make better welds?

Read MoreNew Welding Technologies — Why They Grabbed Attention at NPE

The spotlight in plastics welding and assembly at NPE 2003 was focused on laser, infrared, and ultrasonic equipment.

Read More