Plentiful News in Hot Runners at Fakuma Show

More compact hot runners, even for large parts; smarter controls; unusual nozzle designs; remote mold monitoring; and a new source of LSR cold-runners.

The Fakuma exhibition in Friedrichshafen, Germany, is focused on injection molding—and that includes numerous displays of hot-runner nozzles and controls. Fakuma 2018 in October was no exception, with plenty of news in those categories for everything from micromolding to large automotive parts. Almost all suppliers had something new on hand, though several had already debuted their new entries at NPE2018 in Orlando. Without repeating what was previously reported, there was still a full slate of additional news at Fakuma, reviewed here. (See Keeping Up section for other new mold components at the show.)

VALVE GATES DOMINATE NEWS

Ewikon expanded the range of tip inserts for its nozzles with a version that does not have a permanent valve-pin guide but does have pre-centering for the valve pin the gate area. This design is for when a fully open flow channel is required—e.g., for optical parts, very fast color changes, or reinforced and flame-retardant materials.

For materials sensitive to residence time, such as acetal homopolymer, Ewikon’s valve gates now place the valve-pin seal in a cooled mold insert where it has no contact with the heated hot-runner components. This “cold” valve-pin seal is said to be leakproof and to prevent material degradation in the gap of the valve-pin seal. The thin layer of material that enters and fills the gap during startup acts as a sealing and lubricating film that minimizes wear between the valve pin and seal. This approach was applied first to the company’s HPS III-MH valve gates, but has also been extended to HPS III-S standard nozzles.

In addition, Ewikon introduced its first cold-runner system for LSR, called Coolshot. It’s and electrically driven valve-gate system in which linear stepper motors control each gate individually. Valve-pin positions can be adjusted in steps of 0.01 mm. A controller with 7-in. touchscreen is provided; remote control via tablet is available. A quick-clamping device allows the hot cavity plate to be easily separated from the cold nozzles in case of a lengthy process interruption, in order to prevent curing of the LSR in the cold runner.

Furthermore, Ewikon has joined the trend to web-based remote monitoring of molds. Its new smart Control is accessible by mobile devices and PCs via browser. It monitors hot-runner nozzle and manifold temperatures, number of cycles run, system running time, and downtime. Hot-runner system pressure is optional. It’s a compact box that can be supplied with new hot halves or retrofitted to existing molds. It transfers data via WLAN, Ethernet or USB and can send warning alerts via email or web.

Gammaflux showed for the first time a complete turnkey package consisting of its latest G24 hot-runner temperature controller (18 to 480 zones) integrated with sequential valve-gate control and hydraulic power unit in one device.

Gunther emphasized its recent focus on optimizing micromolding with hot runners, since a cold runner typically weighs more than the part or parts and is the limiting factor in cycle time. Gunther showed a 32-drop valve-gate system capable of molding 2 million nylon or acetal parts/week weighing 0.004 g and having a volume of 0.016 cc. The nozzles were Gunther’s Blue Flow models with a 2.8-mm melt channel and 48-mm total length, all actuated together by an electric-driven plate.

NOVEL DESIGNS

One of the more unusual hot-runner components to be seen at Fakuma was the FDU (Flat Die Unit) nozzle from Haidlmair, so named because of its resemblance to an extrusion flat die for sheet or film. After five years of testing and development, the FDU is now commercially available in sizes from 120 to 280 mm wide for shot volumes of 200 to 2000 g per nozzle. It produces a “slit” gate that allows higher throughput at lower pressure than a conventional round nozzle of similar cross-section. A round nozzle with similar melt-delivery capacity would create a thicker gate that would take longer to cool. In molding parts such as boxes, crates, and appliance parts, FDU has allowed 12% to 25% faster cycles and up to 22% lower pressure. The nozzle is particularly suitable for polyolefins. Versions are available in steel or copper alloy, depending on the material processed. These are open-tip nozzles, but shutoff designs are now in testing. Also, the FDU is currently available only with a Haidlmair mold, but nozzles will be available separately in future.

Also new from Haidlmair is Haiflex, a system using compressed air for quick changing of vent, date, and handle inserts while the mold is in the press.

Haidlmair also promoted its new digital services, including FDM prototyping of plastic parts, laser 3D printing of metal core/cavity inserts for conformal cooling, and CT scanning of sample parts up to 1200 mm diam. height—large enough for molded pallets.

Heitec (represented here by Technoject) introduced what it calls “the next step in side gating”—adding valve gating. Synchro-Valve electric-driven cam action actuates all valves together. The VDC Visio Drive Control comes with a small touchscreen.

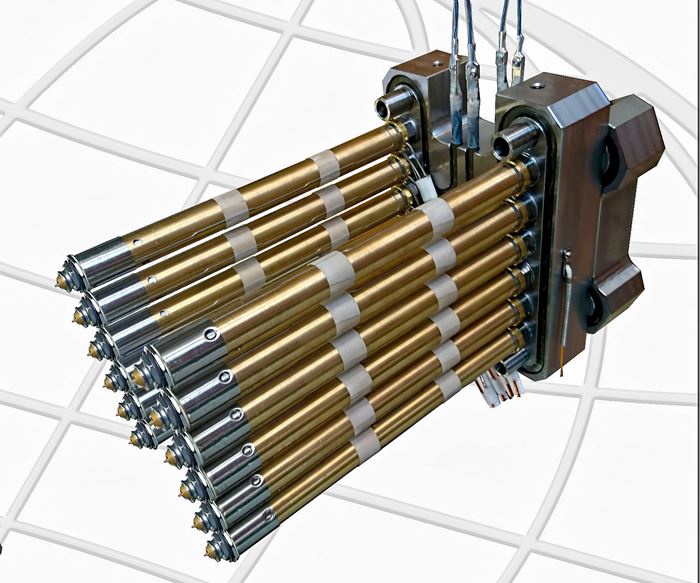

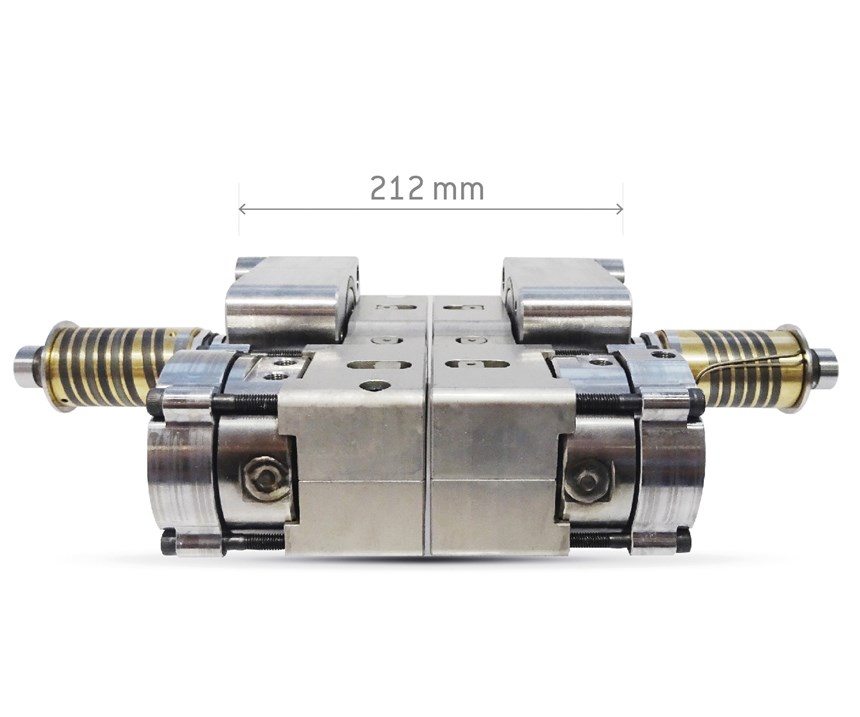

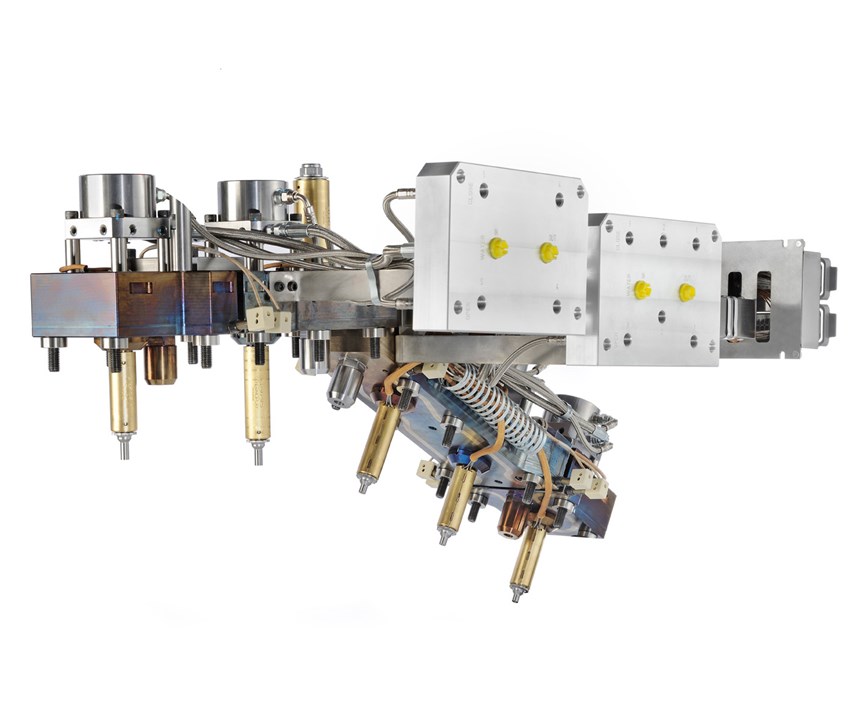

New from HRSflow is a special low-height actuator for valve gates in stack molds (photo). The key to this Compact Stack Mold approach is the staggered arrangement of the cylinders to the side of the nozzle and the use of rocker levers to transmit the movement from the cylinder to the needle. The result is much lower stack-mold heights than when the cylinders and needles are aligned—132 mm for offset nozzles and 212 mm for in-line nozzles (HRSflow’s Ga range for medium to large shots). Available for PP, ABS, and PC/ABS, this new technology is aimed mainly at large parts such as auto bumpers and bins or pallets.

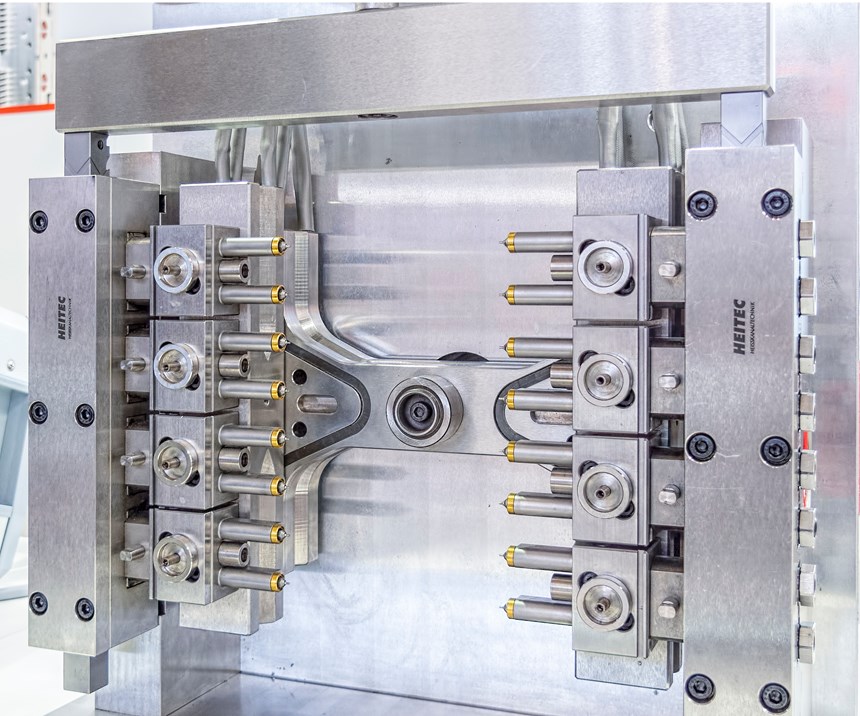

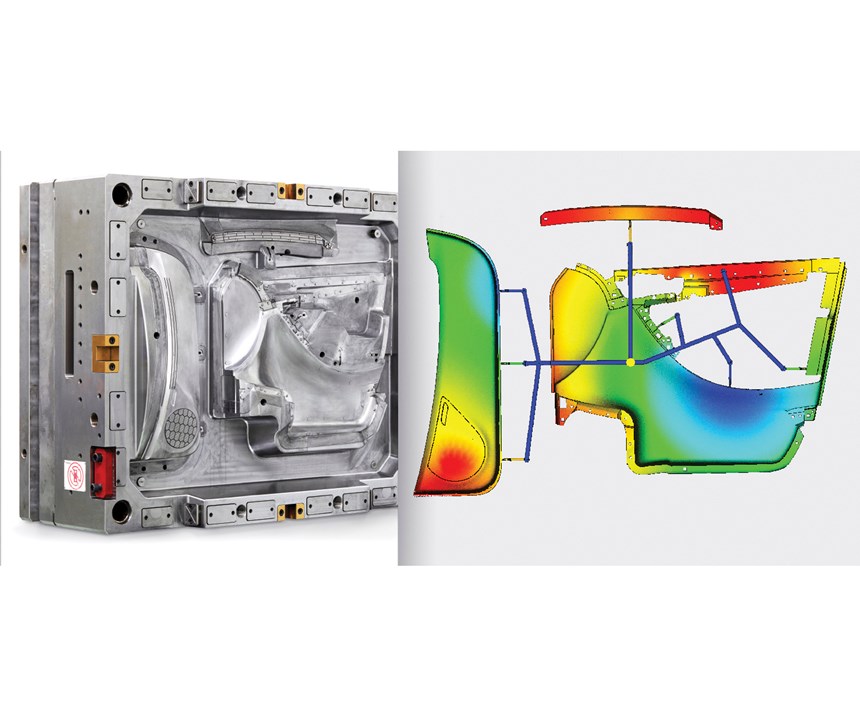

HRSflow also exhibited the first of three demonstration family-mold tools for three very differently sized elements (large, medium and small) of a car door panel. Designed to show off the capabilities of the company’s Flexflow servo-driven valve-gate technology. Three identical molds are being built for HRSflow facilities in Italy, Michigan, and China. The tools are designed to mold three parts in PP or ABS: door liner (560 cc), map pocket (338 cc), and reinforcing bar (58 cc). Average wall thickness varies from 2.3 mm in the largest part to 3 mm in the smallest. Flexflow controls can ensure filling of all three parts simultaneously while preventing overpacking and flashing in the smaller parts. The tool is designed to run in a 1100-ton press. Two pressure sensors in each of the larger cavities, and one in the smallest cavity, provide data on the mold-filling process; and six contact sensors monitor mold deflection during filling.

SLIMMER NOZZLES FOR LARGER PARTS

Slim is in at Incoe, which is broadening its line of Slim DF nozzles, now called Slim-Flo, for multicavity molds. These screw-in nozzles are based on the Direct-Flo series, but utilize the 25% slimmer SBH heater, which is replaceable and has a replaceable thermocouple as well as a second groove for a reserve thermocouple. These slimmer nozzles (hot-tip and valve-gate) allow for closer cavity spacing while still long enough to reach deeply into the mold. The previously introduced DF 3 and DF 5 (the numbers indicate the flow-channel diameter in mm) for shots less than 110 g are now accompanied by the Slim-Flo DF 8 for shots of 30 to 675 g. Its OD has been reduced by 24% to 19.8 mm and the minimum nozzle spacing has been cut by 15% to 27.5 mm. They are available in lengths up to 240 mm.

Incoe says automotive molders have been asking for slimmer nozzles to minimize mold work. As a result, the company has been outfitting its standard DF nozzles with Multipower heaters that integrate all cables inside the nozzle. This feature is available for the DF 8 and 12 (140 to 2000 g shots). Also in development is a slimmer DF 18 version (420 to 3500 g shots) with internal cables. Similar “slimmed” DF 22 and 25 (500 to 9000 g shots) will come later.

Brand-new from Incoe this spring will be commercialization of its more compact HEM hydraulic cylinder for valve-gate nozzles in DF 18, 22, and 25 sizes. (DF 5, 8, 12 with HEM actuator are already available.) For the larger DF valve gates, minimum nozzle pitch is reduced to 51 mm and minimum distance between cylinder and inlet bushing is 55 mm.

Milacron again promoted a novel solution for gating in the center of round parts with center holes. The Mold-Masters Core Ring valve gate, which was shown in developmental form as a conceptual model at Fakuma 2017 (see Dec. ’17 Close-Up for illustration), has a stationary pin to form the center hole in the part (such as a gear) and a reciprocating sleeve that moves up and down to open and close the gate. Melt is thus distributed uniformly around 360° for balanced filling without knit lines and uniform shrinkage, and no visible gate (Milacron has referred to this as the “No-Gate” nozzle).

Also new is the Mold-Masters ThinPak series of hot-runner systems for thin-wall packaging. New nozzles, gate seals and manifold designs are engineered to withstand high pressures up to 2800 bar (40,600 psi), 40% higher than standard Mold-Masters manifold designs. The robust gate seals are serviceable from the parting line. The gate has a beefed-up design using high-strength materials and a larger contact area. The valve-disk bushing reportedly controls any weepage and directs it to easily cleaned areas—a feature said to extend service intervals by up to three times. Further, Milacron says the new nozzle and manifold seal provides greater reliability, even on cold startup, allowing for a wider processing window.

One of two new developments from PSG, part of Meusburger Group (see below), is the SmartFill Shot 4557 series, a larger size of screw-in valve-gate nozzle (hydraulic or pneumatic) with flow channels up to 22 mm diam., vs, 18 mm for the next-largest 4547 size. Nozzle lengths are100 to 680 mm. These units have the thermocouple spring-loaded against the nozzle body.

A new version of PSG’s profiTemp+ hot-runner temperature controller handles up to 192 zones, vs. a maximum of 120 zones for a single device before now. Also new is a hydraulic valve-gate sequence controller, which provides two different opening speeds for up to 12 zones independently.

Thermoplay of Italy has several new products. One is a new series of valve-gate nozzles for fast cycles. They feature enlarged melt channels for fast injection and improved thermal exchange between pin and cavity plate for faster cooling of the gate area and an attractive gate vestige. A new, patented system is said to minimize leakage between pin and pin guide. This new design is available for FN (24 and 32 mm diam.) and DN (22- and 30-mm) nozzles.

In addition, Thermoplay has a new hot-runner system for molding large parts for automotive, appliances and pallets. These prewired sequential valve-gating systems use a new system of joints that distributes thermal expansion of the manifold and allows use of significantly shorter threaded nozzles than would otherwise be used. Another important aspect cited by the company is savings provided by reduced thickness of the nozzle plate in this system.

Thermoplay also brought out a new temperature controller (TH-M6 EVO HP) with up to 240 zones, 15-in. touchscreen display, USB port, and optional WLAN remote connection for online technical assistance and remote adjustment of settings and testing of electrical connections.

There’s also a new, compact and low-cost TH-M6 model with just three zones. It has the same features as six- and 12-zone models in this series, including a wide touchscreen display.

Also new is a sequential controller for up to 16 valve gates (hydraulic or pneumatic). It has a hand-held pendant with 6.5-in. touchscreen.

Related Content

Impacts of Auto’s Switch to Sustainability

Of all the trends you'll see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

Read MoreDesign Optimization Software Finds Weight-Saving Solutions Outside the Traditional Realm

Resin supplier Celanese turned to startup Rafinex and its Möbius software to optimize the design for an engine bracket, ultimately reducing weight by 25% while maintaining mechanical performance and function.

Read MorePlastic Compounding Market to Outpace Metal & Alloy Market Growth

Study shows the plastic compounding process is being used to boost electrical properties and UV resistance while custom compounding is increasingly being used to achieve high-performance in plastic-based goods.

Read MoreK 2022 Preview: Engineering Materials for Sustainability and E-Mobility

Materials that are sustainable yet offer equal performance to their fossil-based counterparts will be prominent at K 2022.

Read MoreRead Next

News in Hot Runners & Tooling At Fakuma 2017 Show

Highlights included some unusual solutions to common problems, slim nozzles for close spacing, and controls with lots of zones, as well as a handful of new cost- and space-saving standard mold components

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.png;maxWidth=300;quality=90)