Prize-Winning Mix-It-Yourself Cocktail Package Comprises Two Snap-Fit PET Bottles

Shelf-stable fruit juice on top, premium liquor on the bottom.

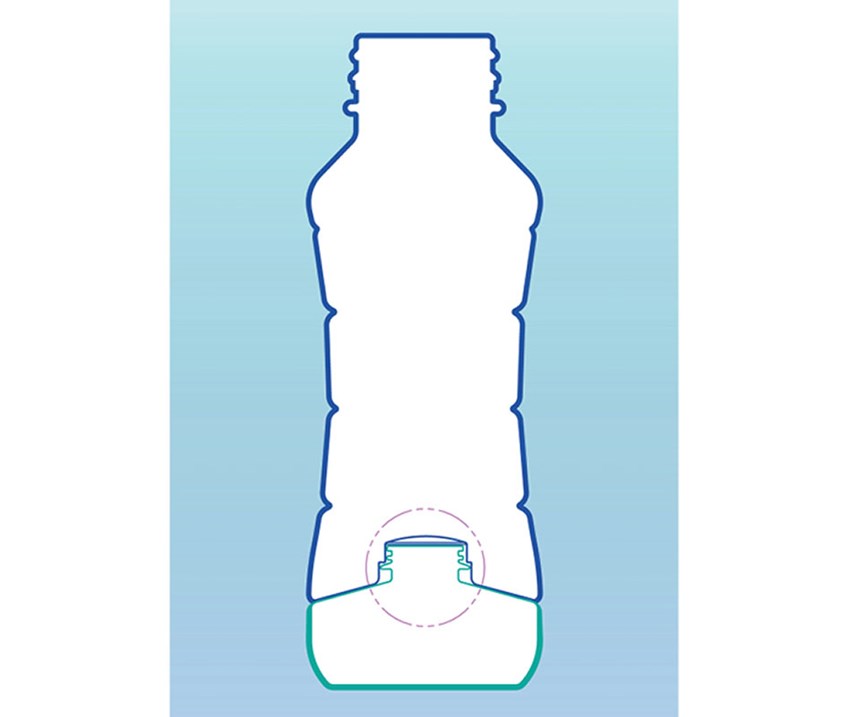

The “Clasper” bottle, engineered by Plastic Technologies, Inc. (PTI), Holland, Ohio, won the 2017 AmeriStar Package Award in the alcoholic beverages category from the Institute of Packaging Professionals (IoPP). This novel two-compartment package consists of two separate, snap-together PET bottles and a shrink label with a tearable perforation to allow separation of the top and bottom compartments. The upper main bottle that holds 6.5 oz of hot-filled, shelf-stable fruit juice and is topped by a 38-mm PP cap. The bottom bottle holds 50 ml of premium alcohol and has a heat-applied foil seal.

The bottle concept was conceived by Alex Garner, founder of beverage company Yumix LLC, Austin, Tex. He imagined a mix-it-yourself fruit-juice cocktail in which the ingredients were stored separately to keep enzymes in the juice from altering the taste. Premixing would have required adding preservatives and sweetener, which would have altered the flavor profile. Yumix launched the portable, shelf-stable cocktail line last fall.

According to PTI, the biggest challenge in designing the package was getting the components to snap together and stay together—further complicated by the 185 F hot-fill requirement. The base of the top bottle is highly susceptible to deformation during hot filling—an effect magnified by the unusually large headspace left for addition of the alcohol component during use. PTI used ribs instead of vacuum panels to add structural stability without compromising the aesthetics. Creating the bottom alcohol container was also challenging because it is so short and wide relative to its 20-mm finish. A tiny preform had to be developed for this bottle.

Related Content

-

As Currier Grows in Medical Consumables, Blow Molding Is Its ‘Foot in the Door’

Currier Plastics has added substantial capacity recently in both injection and blow molding for medical/pharmaceutical products, including several machines to occupy a new, large clean room.

-

50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

-

Get Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.