A lot has changed at Custom Profile Inc. since Plastics Technology featured this Grand Rapids, Mich., extrusion processor in 2013. Back then, it was in the process of replacing a tangle of four different enterprise software systems, some of them home-made, with a single new system to better manage its growth. Since then, the extrusion operation has continued to add technology at its headquarters plant, ventured into the medical market through an acquisition, expanded its product offerings and opened up a third plant in the Southeast as part of its strategy to locate facilities closer to customers. The result has been a dramatic increase in sales, from about $25 million in 2012 to roughly $45 million now.

Most recently, Custom Profile has brought on extrusion veteran Steve Maxson as v.p. of sales and marketing. Maxson, who has more than 20 years of sales and marketing experience with both extrusion machine builders and processors, will be driving the firm’s sales, marketing and product-development programs as well as contributing to its acquisition strategies.

Custom Profile has 19 lines—single- and twin-screw—at its headquarters plant in Grand Rapids, including two devoted to tooling validation and product development.

Custom Profile serves a variety of markets, notably office furniture, appliance, renewable energy, construction, irrigation, fitness and medical—the last two end markets came on board with the 2016 acquisition of the profile extrusion business of Wisconsin-based Bemis Manufacturing Co. Medical products are produced now at Custom Profile’s plant in Mexico.

Custom Profile runs a wide range of commodity resins, including ABS, ABS/PC blends, HIPS, PE, PP, TPEs and flexible and rigid PVC. “We centralize buying out of Michigan for all three plants to give us economies of scale,” Maxson says. “We also try to introduce regrind where possible, at levels up to 100%.” Custom Profile runs more than 500 different colors, and has a QC lab equipped with spectrometers and other technology to validate precise color matching.

In Grand Rapids, Custom Profile runs 19 extrusion lines, a combination of single-screw machines of various sizes from Davis-Standard, US Extruders and Graham Engineering’s American Kuhne brand, together with a twin screw from Milacron to run PVC powder. With 110,000 ft2 of manufacturing space and 150 employees, the plant is the largest of Custom Profile’s three facilities. In Grand Rapids, the company dedicates two production-sized lines with coextrusion capabilities for product development, prototyping and tool validation.

Custom Profile builds its own extrusion tooling in Michigan, where its toolroom is equipped with wire-EDM and CNC machines. This gives the firm complete control over quality and reduces lead times. Having the ability to build tools in-house is also more cost-effective for the company because the profiles it produces tend to be highly customized and intricate. About one-third are multi-durometer and tri extrusions, which place an even greater emphasis on tooling quality.

Custom Profile opened a plant in Juarez, Mexico, in 2008 in response to a move by the appliance industry and others to shift production to that region. The plant has 52,000 ft2 of manufacturing space and 185 employees. This plant operates nine extrusion lines, two of them in a Class 8 clean room built in 2018 for medical tubing. “The acquisition of Bemis gave us a position in medical, including burette tubing for delivering intravenous drugs,” Maxson states. “That was our foray into medical. That customer base came along with the purchase, and we put a cleanroom in Mexico for manufacturing and added new extrusion capacity.”

Last year, Custom Profile brought in extrusion veteran Steve Maxson to head up sales/marketing and product development and to help identify acquisition targets.

A little more than a year ago, the company cut the ribbon on a third plant, in Camden, S.C., with six extrusion lines, 70,000 ft2 of manufacturing space and 52 employees. Maxson says Custom Profile built the plant to be closer to several key customers in appliances and lawn mowers.

“We’re looking for business-development person, a ‘hunter’ who can go after new applications and new clients that leverage our existing capabilities.”

The firm runs all of its plants around the clock, five days a week. Explains Maxson, “We run pretty much same products in all three sites. While tooling development is centralized in Michigan, we have basically the same lines and the same profile production capabilities at each. This helps us mitigate risk in the event production is somehow disrupted in one location.”

Custom Profile also has mitigated its business risk by being active in many different markets. Maxson notes, “Our two biggest markets are office furniture and appliance. Office furniture is down now because of the pandemic, but the appliance industry is very strong because housing is booming. We are also seeing increases in niche markets like renewable energy, as we do profiles and tubing for wind turbines. We also develop intricate profiles for indoor vertical farming towers that are becoming popular for farmers of small plants. These towers are constructed from these profiles. The idea is for farmers to increase crop yields while minimizing horizontal farmland space. The plants are vertically stacked in a controlled environment.”

These wire-management clips are extruded and cut at high-speeds to create a product that is more typically molded. A process developed in-house permits Custom Profile to apply an adhesive strip inline after the profile is cooled.

Kicking it up A Notch

The more successful processors like to talk about their value-added services to distinguish themselves from manufacturers that are just part producers. In profile extrusion, these extra services usually consist of secondary operations like notching, hole punching, embossing and the like. Custom Profile provides many of these services inline—and not as secondary processes—to reduce overall costs and improve lead times.

Notes Maxson, “When we’re asked about our value proposition, the first thing we talk about is our people. Many have been here 15+ years. Also, we honor our commitments; respond faster than our competition; pursue zero defects and 100% on-time delivery; and recruit, develop, and retain employees.” The company currently delivers on time at a rate of 99.9%.

Maxson continues, “We also leverage our technology; we’re are constantly investing in new equipment to enhance our extrusion capabilities. We provide great service and on-time delivery of custom extrusions. But we are good at inline operations—punching, printing, adding adhesive tape, embossing, notching. We have developed expertise at doing them as part of the extrusion process. Combining people and technology, we focus on improving and streamlining our processes, which is how we have become experts at in-line finishing operations.”

“We also leverage our technology; we’re are constantly investing in new equipment to enhance our extrusion capabilities.”

That expertise has not only improved efficiencies at Custom Profile, but it’s opened new markets altogether, Maxson notes. “Sam Nicholas founded the company in 1992, and he developed tooling and process technology for many applications that reduce overall costs to our customers.” For instance, Custom Profile extrudes clips that are used to manage wires in appliances. Typically, these clips are injection molded, with an adhesive backing applied in a secondary process. But Custom Profile extrudes them as a continuous profile, applies the adhesive strip inline after cooling, then cuts the profile at extremely high speeds with a two-blade servo cutter, Maxson explains.

Custom Profile got into the medical market by virtue of an acquisition and makes burette tubing in a cleanroom in Mexico.

Ownership Change

Like many in the extrusion business, Custom Profile has humble origins. When Nicholas opened the doors to a 300 ft2 facility in 1992, he was the first and only employee and had one extrusion line. In 2012, Nicholas sold to Blackford Capital LLC, a private equity firm in Grand Rapids. It has since been acquired by Mosaic Capital Partners of Charlotte, N.C., an employee-ownership private-equity firm, and Maxson has been brought on as part of a rebranding effort and growth strategy.

He states, “I was brought in to build up a team. We’ve done a great job growing, but a lot has been organic, getting additional projects from existing clients. Now, we’ve hired an inside salesperson. We’re looking for a business-development person, a ‘hunter’ who can go after new applications and new clients that leverage our existing capabilities. It’s not often that you get the opportunity to rebrand a company and put in place a new selling strategy.”

Related Content

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreCooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

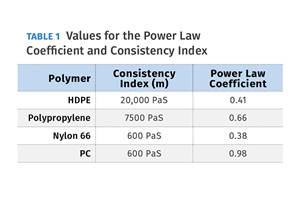

Read MoreThe Importance of Viscosity in Melting

The calculations required to determine the right melt temperature for each polymer are complicated. Knowing the power-law coefficient and the consistency index of the polymer you run might prove useful.

Read MoreRead Next

Enterprise Software Solution Smooths Custom Extruder’s Growth

Sometimes an operation can grow too quickly, even beyond its ability to manage the new business. Custom Profile solved this problem by replacing off-the-shelf and home-made enterprise software with one comprehensive package.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More

.png;maxWidth=300;quality=90)