'Purge on the Fly' with Ultra Purge

Chem-Trend demonstrates its Ultra Purge product line with this Digital Demo.

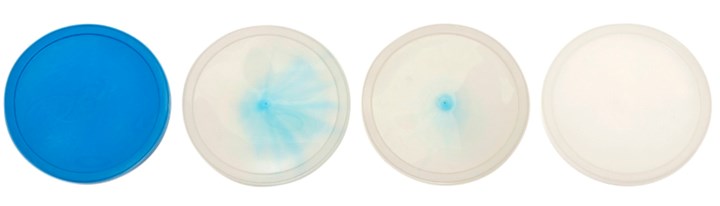

"Purging on the Fly" is a unique solution offered by Chem-Trend’s Ultra Purge product line that allows injection molders to mold parts while purging. Ultra Purge is efficient at removing carbon along with reducing downtime and scrap during dark to light color changes. This video demonstrates the ease with which an injection molding machine and hot runners can be cleaned by utilizing the Ultra Purge “purge on the fly” technology.

Why it matters:

- Removing residue and color from hot runners is challenging with no truly efficient solution available, until now.

- Designed to purge the machine “on the fly” requiring no change of machine settings and no soak time during the purging process.

- Contributes to a reduction in machine downtime and waste without any additional capital expense.

In a trial of Ultra Purge™ 1000, one thin-wall packaging injection molder was able to reduce downtime from 4 hours to 1.5 hours when undergoing a color change from blue to white, resulting in a 63% reduction in time spent, and 68% reduction in scrap due to a more efficient and complete cleaning.

Request your free sample today. CHEMTREND.COM/contact

.png;maxWidth=970;quality=90)