Pyramid’s Relentless Pursuit of Quality

Instilling a culture of quality, and the ability to offer tooling from a sister company, are pushing Pyramid Plastics to new heights.

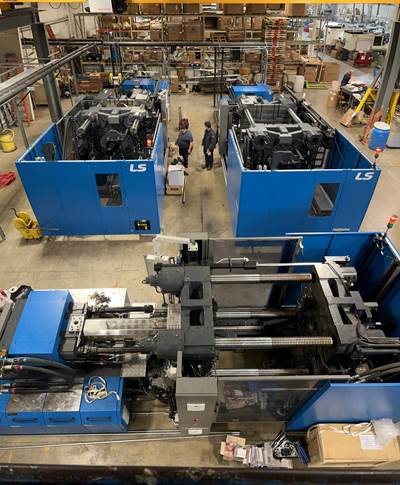

Based in Rockford, Ill., Pyramid Plastics is part of the Pyramid Molding Group, alongside Industrial Molds. (Photo: Pyramid Plastics)

Improving quality has an immediate impact on an injection molder’s bottom line and productivity. But just as important, if less quantifiable, is the effect on client mood. “We’ve saved a lot of money,” Andrew Peterson says, “and we have happier customers—you can’t put a price on that.”

Peterson, COO of the Pyramid Molding Group, which includes custom injection molder Pyramid Plastics and toolmaker Industrial Molds, both of Rockford, Ill., made quality the primary emphasis of the molding business when he took over company’s day-to-day operations.

“When I came to Pyramid Plastics in late 2019, quality was our number one issue,” Peterson says, “and it affected every department—production, accounting, scheduling, customer service, shipping—so we really made it a cultural focus.”

Quality became an overriding focus for Pyramid Plastics and key to a new work culture. (Photo: Pyramid Plastics)

Peterson stepped in for his father Tim Peterson and uncle, Eric Peterson, after he spent 10 years at Industrial Molds, which was started in 1968 by his grandfather, Jack Peterson. Jack invested in Pyramid Plastics (founded in 1976) in the 1990s before eventually taking it over. Both businesses are run independently today but under the new unified brand of Pyramid Molding Group, created in 2020.

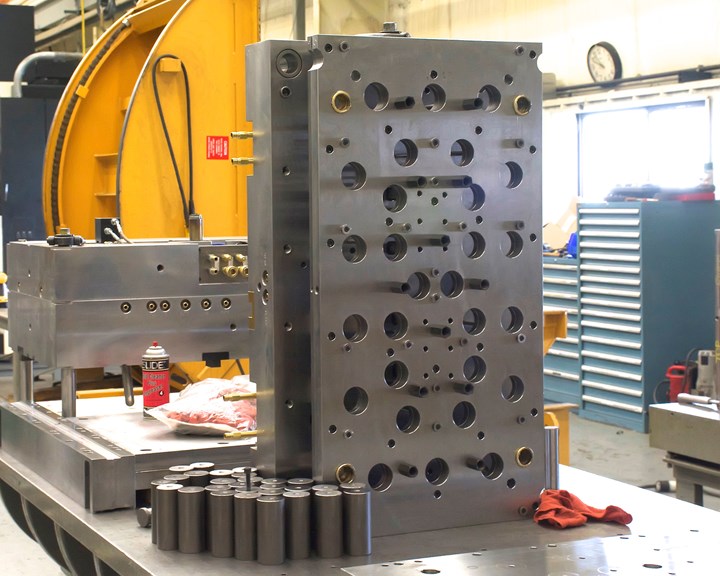

Injection moldmaker Industrial Molds was founded by Jack Peterson in 1976. (Photo: Industrial Molds)

Pyramid’s Scheme

His first decade spent on the tooling side after graduating from Wright State University in Dayton, Ohio, informs how Peterson runs the companies today as independent businesses but with a symbiotic relationship. “In 2021, we changed strategically how we marketed,” Peterson explains. “We saw a lot of consistency in plastics. From a business standpoint, it’s more predictable and a lot more steady, so we wanted to focus on selling our plastics, and that would in turn give us sales in our tool shop.”

The strategy has proven effective, according to Peterson and Pyramid Plastics’ production supervisor Chase McNitt, with approximately 35% of Industrial’s new mold sales running on Pyramid’s molding machines. “The molding cash flows are much more reliable, the workflow is reliable,” McNitt says, “and in turn, it does drive tooling sales, whereas the other way around didn’t drive molding sales.”

“Plastics molding provides a lot more stability and a lot more room for growth. And obviously, if we’re awarded the plastic part, we know a pretty good toolmaker who just happens to have availability.”

Pyramid Plastics converted storage space to manufacturing space to accommodate three new LS Mtron hybrid injection molding machines, two 1000-ton and one 500-ton. (Photo: Pyramid Plastics)

Pyramid Plastics recently boosted the availability of its molding services by installing three new hybrid LS Mtron ONE injection molding machines, including two 1000-ton machines and one 550-ton press. Pyramid now has 30 injection machines, ranging in clamp force from 40 to 1000 tons. To accommodate the new machines, the company increased its production floor square footage by 12%, converting 3200 ft2 from storage to manufacturing.

“With IQMS as our ERP system, we’ve been able to drastically improve our inventory.”

The company also installed a new 7.5-ton Konecranes overhead crane, which joined an existing 10-ton crane. The new crane allowed Pyramid, which occupies approximately 43,000 ft2 and employs 55, to put the machines closer together, further maximizing floor space, as did a switch to standup forklifts.

The machine additions, and the upgrades to power, water and air that they required, are phase one of a three-year plan to expand the business. Subsequent phases include the intention to add three to five new machines annually for the next two to three years, replacing aging presses and adding new capacity.

Established in 1968, Industrial Molds occupies 46,000 ft2 and builds 150 molds/yr plus engineering changes. (Photo: Industrial Molds)

McNitt jokes that several of the machines Pyramid swapped out were old enough to purchase alcohol. In addition to youth, the new presses have boosted productivity over their older counterparts by 20-40%. When Plastics Technology visited, one of the new 1000-ton machines was molding a large appliance component in a 40% faster cycle and without the need for mold release, which had been applied to the tool cavity every two shots on the former press. Featuring greaseless tiebars and an automatic door, the new machines are cleaner and friendlier than their predecessors, McNitt says. “It’s the little things,” he adds.

A portion of the square footage reclaimed by Pyramid came from removing storage racks that were made obsolete by optimizing the company’s inventory. That was made possible by the adoption of DelmiaWorks Manufacturing ERP (formerly IQMS), which the company began using in 2017.

“With IQMS as our ERP system, we’ve been able to drastically improve our inventory,” Peterson says, “both the locational accuracy, and also how much is there. With that better inventory control, we were able to take some square footage that was used for storage and make that manufacturing space.” The company also maintains an offsite warehouse where it stores all its finished goods and raw materials.

Bye-Bye Binders

Quality at a molding shop starts with the operators, and the operators start with work instructions. When Pyramid looked to establish quality as job one, it began with those work instructions. Gone were the binders, although they might not have been missed. “There were these big binders that everyone was supposed to read and no one ever did,” Peterson says. These were replaced with simpler three-to-five-page instructions, heavy on images and written in English and Spanish.

A Pyramid Plastics employee handles molded parts with work instructions on hand to guide her. (Photo: Pyramid Plastics)

“We actually got rid of about 35-40% of our quality paperwork because it was either deemed redundant or just ineffective,” McNitt says. “So we reduced our workload but improved the output.”

Going a step further, Pyramid Plastics assigned numbers to all their jobs, based on difficulty, and to their operators, based on skills. When it comes time to schedule production, these rankings figure prominently. “We rated all our jobs and then rated our operators,” Peterson says. “That’s on the tables out there so we can see if we have a mismatch in skill level to the job, and if so, we can increase our quality inspections.”

“We really try to think big. When you’re doing something, you need to ask if it’s scalable.”

Pyramid Plastics uses a panel consisting of the quality department, lead operators and the supervisor to rank its operators across eight categories on a scale of one through five every quarter. In addition to helping to match jobs with operators, these rankings also serve as a basis for the workers’ pay scale, incentivizing them to continuously improve.

“You find out that some operators are really good at this and maybe not so good at that, and you didn’t think about it until the data was there,” Peterson says. “So we’ve been able to maximize their strengths and train to their weaknesses.”

The addition of numerous secondary operations at Pyramid Plastics has helped fuel the company’s recent growth. (Photo: Pyramid Plastics)

Thinking Big(ger)

Beyond easier conversations with customers, Pyramid’s relentless pursuit of quality has also afforded the company something else—a chance to grow. “If you have late delivery or quality issues, it makes it hard to grow,” Peterson says. With a goal of achieving $25 million in sales by 2025, Pyramid Plastics needed to grow 20% per year. It’s currently growing at a rate of 30% annually.

“We really try to think big,” Peterson says. “When you’re doing something, looking to make a change, you need to ask if it’s scalable. And then you plan for tomorrow, not today. I think that’s been huge.”

Pyramid Plastics owns its own truck and trailer, providing free delivery to local customers.

(Photo: Pyramid Plastics)

Related Content

Injection Molder Bases Company Culture on Employee Empowerment

After more than two decades in the industry, Rodney Davenport was given the opportunity to create an injection molding operation in his own vision, and — in keeping with the product he was making — to do so from the ground up.

Read MoreUS Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Read MoreA Recycling Plant, Renewed

Reinvention is essential at Capital Polymers, a toll recycler that has completely transformed its operation in a short period of time.

Read MoreGeneration Gap? Not at Packaging Personified

Started at a kitchen table and now in its third-generation of family involvement, this vertically integrated supplier of flexible packaging traces its success to closely aligning with customers and continually investing in new technology across its films, printing and converting operations.

Read MoreRead Next

Injection Molding: Servo-Hydraulic Line of Toggle-Style Machines Headed Stateside

Korea’s LS Mtron will be offering its WIZ-TA series of servo-hydraulic toggle injection molding machines in the U.S. with clamp forces ranging from 55 to 420 tons.

Read MorePyramid Plastics Adds Three Molding Machines

The Rockford, Ill. based custom injection molder installed three new LSMtron ONE machines and will invest $2 million in new equipment and capabilities in 2022.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More