Recycled Resin Market Expected to Be Strong in 2014

RPET prices are expected to rise this year. Recyclers expect a strong year for R-HDPE, too.

Recycled product pricing pretty much held its own over the last year. Despite some new laws and some surprise market delays, recyclers still felt optimistic going into this year.

Perhaps the biggest story in 2013 was The Green Fence. That is the Chinese policy that went into effect in February, strictly enforcing regulations on importing dirty scrap materials—from the U.S. and elsewhere. It led to a significant drop in imports of plastic waste and even put some U.S. recyclers out of business, at least temporarily. Recent crackdowns have required Chinese companies to import only those recycled materials that have gone through some kind of processing. It's no longer enough for waste just to be clean and sorted, industry sources say. They report that some municipal recycling facilities (MRFs) are responding to the Green Fence by trying to clean up waste with limited technical capabilities. Since the waste quality is still inferior, the MRFs are getting a lower domestic price for their waste. Industry sources say some lower-quality clear RPET flake has been offered for as little as 53¢/lb, below the more typical price range of 55-56¢/lb (see table below).

RPET DEMAND SURVIVES CHINESE SLUMP

While the Asian market was soft in last quarter, PET flake prices have been pretty stable over the course of 2013. Today, Chinese are still buying but the market is mostly domestic, one recycler said. The U.S. domestic price is a couple of cents higher than the Chinese price (they used to match). Also, Mexico is dumping a lot of washed flake in California, one source said.

While January is usually a slow month, recyclers expect RPET prices to rise over the year, at least on the West Coast, with the return of California state incentive programs to use recycle. “People will be fighting over the bales,” one West Coast source predicted.

R-HDPE DEMAND PICKS UP

Recycled HDPE experienced an unpredictable year, with a strong first quarter, and two dead quarters after that. However, since July, momentum has been building. HDPE pipe has been driving the market, though seasonal construction demand picked up about three months later than recyclers had expected.

According to one recycler, “The mixed-color market had softened quite a bit over the summer with the pipe industry not being able to lay pipe because of all the rain. Now the pipe market picked up again and there is a little more supply.”

The mixed color market HDPE is still a bit soft. Major pipe maker ADS now has two recycling plants of its own and has switched from buying pellets to buying bales. One recycler reports that colored and natural bale pricing grew very close in the spring. “Then it got to be the widest delta—22¢/lb—we’ve ever seen. Part of that was excess supply ADS was not taking and that wasn’t going to China either.

“We expected things to fall off by December, but a week and a half before Christmas, demand still looked strong. Material now is hard to come buy. However, we are now facing cold weather, snow and ice, so we will see what happens. Virgin prices seem to be holding and that affects recycle prices.”

Overall, recyclers predict that 2014 will be a stronger year for HDPE than 2013.

Related Content

New Facility Refreshes Post-Consumer PP by Washing Out Additives, Contaminants

PureCycle prepares to scale up its novel solvent recycling approach as new facility nears completion.

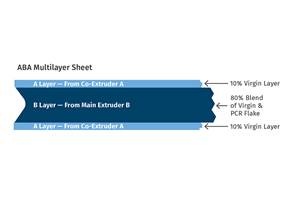

Read MoreThermoforming PCR: An Equipment Supplier’s Pointers

Thermoforming PCR is not radically different from forming virgin, but variation in recycled materials can require extra care to get a consistent end result. Start by examining every aspect of the process from the sheet (and extrusion process if run inline) to the final trim.

Read MoreResins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More

.png;maxWidth=300;quality=90)