Revisiting Shot Size vs. Barrel Capacity

We’ve covered this topic before, but it’s important enough to warrant another look..

While I’ve written on this two on two separate occasions (see March 2017 and October 2011 Injection Molding Know-How columns), I think it’s important enough to warrant yet another examination. There are hundreds of variables associated with developing an injection molding process, so it’s easy to let this not-so-obvious variable fall through the cracks.

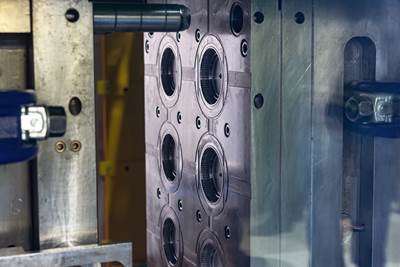

Typically you determine the shot size that can fill and pack the part(s), and work up a process from there. Suppose that everything seems OK, the process is stable, cycle is repeatable, and things look good. Parts even look good. Unfortunately, when you submit parts to quality control, some of them meet specifications and others don’t, while some—not all—fail performance tests. This could be due to size, appearance or even warp issues. One possible reason for these types of issues is that you are using too small or too large a shot size.

One critical issue for all injection molding processes is the quality of the melted plastic. Is it uniform in temperature, viscosity, composition? Is there unmelt or partially melted granules within the part? Are there swirls or streaks of color or shade differences in some parts? These issues may be hard to measure, monitor or document, but they will ruin performance and production. If the plastic granules are not melted properly and uniformly all the above and more could be inviting “Murphy” to your production run. In terms of melt quality, all you can do is pay attention to the processing variables that influence the melting process and melt quality?

So what are those variables? My list includes:

1. Percentage of barrel capacity for the shot size.

2. Type of resin you are working with (amorphous or semi-crystalline); is there any filler, and if so what type?

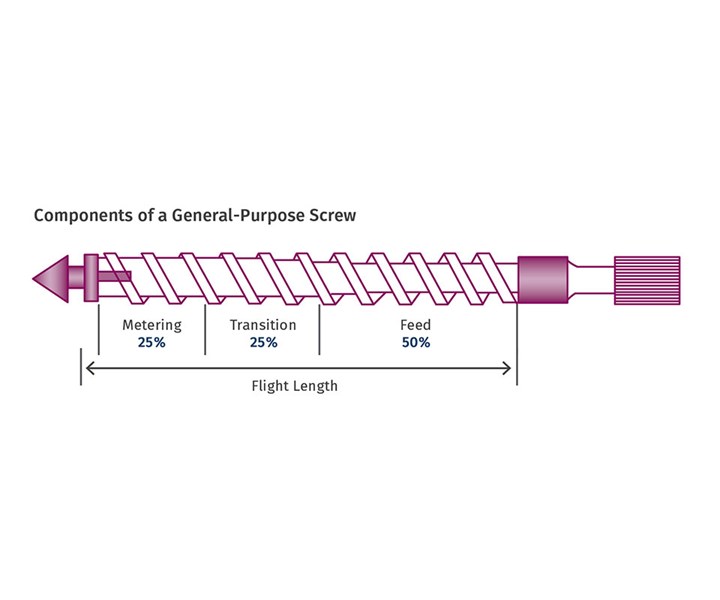

3. Design of the screw—its length-to-diameter ratio or L/D; whether it is a general-purpose (GP), barrier, mixing, or other type of screw. For this article, the focus will be on the GP screw. It is the one most often used, but please note: I do not recommend them.

4. Shape and size of the granule or pellet.

5. Consistency of granule size.

6. Types and sizes of heater bands.

Here, I will focus on only the first two on the list. For me, it would be ideal to be able to view what actually happens as the plastic granules enter the feed zone then transfer to the transition zone and finally go through the metering zone to provide melted plastic for the shot. Unfortunately, that capability does not yet exist. But between studies and observation of processing plastics, running different screws, and most importantly pulling screws and analyzing what is happening in the feed, transition and metering zones, I can offer some guidance on what percentage of the barrel should be used for injection molding.

Let’s start with this question: What percentage of barrel capacity should be acceptable for proper melting? Use 25% to 65% of the barrel capacity for your shot size. Less than 25% will unlikely yield a uniform melt. Most would agree that for a shot size less than 25% of the maximum barrel capacity, the concern is residence time. While that is an issue, I have also found that the melt quality is often poor. Logically you would assume the long residence time would thermally melt the granules. This assumption may be logical, but think of it from the screw’s perspective.

Lower rpm and short screw-rotation times combine to provide a non-uniform melt.

With a GP screw (see illustration below) you have three sections: feed, transition and metering. Why no melt uniformity? Next time you run a job that uses less than 25% of the barrel capacity, notice the low screw rpm and, more importantly, count how many revolutions it takes to make the shot size. Note that recovery time is short even with low rpm. The big culprit is that the screw does not turn many revolutions. Those few turns and short recovery times prevent the screw from doing its normal job of properly melting the granules via shear and compression.

With GP screws, if you run less than 25% of the barrel capacity, you’ll get poor melt quality because of low rpm and a small number of screw turns needed to make the shot size. If you run greater than 65% of barrel capacity you’ll get only 3.5 flights to pick up the granules, compress them and prepare them for the transition or melting zone.

With GP screws, if you run less than 25% of the barrel capacity, you’ll get poor melt quality because of low rpm and a small number of screw turns needed to make the shot size. If you run greater than 65% of barrel capacity you’ll get only 3.5 flights to pick up the granules, compress them and prepare them for the transition or melting zone.

Will thermal energy migrate evenly through the barrel wall to the wad of plastic in the flights? Remember ~80% of the energy to melt the plastic should come from shear, not the barrel heaters.

With shots greater than 65% of the barrel capacity, the screw does get to rotate at proper speeds, but now you have a different situation. Note what happens to the granules as they fall into the feed section of the screw. On a typical 20:1 L/D screw, there are 10 flights for feeding. At 65% of the shot size, that means 6.5 flights are “behind” the feed throat and thus empty. That means there are only 3.5 flights available to pick up the granules, compress them and prepare them for the transition or melting zone. There is a thermal aspect to melting, even if relatively small, but with a large shot size does the feed zone get enough time to provide whatever thermal effect is needed? That question requires some understanding of the resin type—is it amorphous or semi-crystalline?

You might be OK if you are running an amorphous resin, but you are inviting Murphy to your process if you are running a semi-crystalline material. Why the difference? It has to do with how each of these resin families melt:

• Amorphous resins melt like margarine or butter. As energy is applied, they soften and eventually melt. In addition, they take less energy to melt. For example, ABS is an amorphous resin and takes ~150 BTU per lb (454 g) to bring it from room temperature to a molten state.

• Semi-crystalline resins melt like ice; they stay hard until they reach their melting point. They do not soften gradually until they reach their melting temperature. Moreover, they take twice as much energy to melt. For example polypropylene takes 300 BTU/lb.

Therefore, if processing a semi-crystalline resin using a large shot size, you will have only two to four flights of the feed section to start the energy transfer. In addition, you will be expecting the transition zone to supply nearly all of this energy. Turns out this is wishful thinking and, unbelievably, PP or PE will literally grind metal off the flights of the screw when using large shot sizes, especially when they are greater than 65% of the barrel capacity.

In short, there are lots of variables to pay attention to when injection molding, but do not forget to check out how much of the barrel you are using to make parts. Too big or too small shot sizes relative to barrel capacity can bring on major problems. Granted this is easier said than done with the pressures of production, but do check barrel capacities when scheduling jobs. Keep Murphy at bay.

About the Author

John Bozzelli

John Bozzelli is the founder of Injection Molding Solutions (Scientific Molding) in Midland, Mich., a provider of training and consulting services to injection molders, including LIMS, and other specialties. Contact john@scientificmolding.com.

Related Content

How to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreHow Much L/D Do You Really Need?

Just like selecting the extruder size and drive combination, the L/D should be carefully evaluated.

Read MoreHow to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

Read MorePBT and PET Polyester: The Difference Crystallinity Makes

To properly understand the differences in performance between PET and PBT we need to compare apples to apples—the semi-crystalline forms of each polymer.

Read MoreRead Next

A Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More.jpg;width=70;height=70;mode=crop)