Robots at NPE2012: Faster, Stronger, Smarter

Among the many attractions in injection molding exhibits at NPE2012 were more intelligent robots with higher speeds and payload capacities

More intelligent robots with higher speeds and payload capacities were among the many attractions in injection molding exhibits at NPE2012 in Orlando, Fla. Some of the new models are also designed for greater economy. In addition, several new developments in end-of-arm tooling (EOAT) were presented. (For the full picture of new robotics entries, see our show

preview in March, and also check out our reviews of new injection

machinery in June and hot runners/tooling in July.)

SUPER-FAST SIDE ENTRY

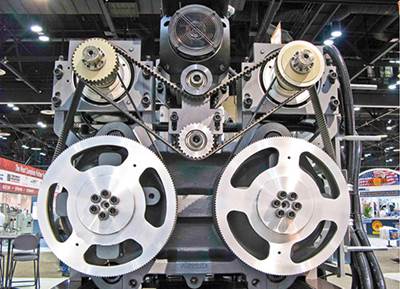

One of the highlights of the molding exhibits were lightning-fast side-entry robots. As reported in March, Hekuma demonstrated its new Heku DS model with speed up to 10 m/sec and acceleration up to 30G. Also, CBW Automation demonstrated its new telescoping side-entry (TSE) robot, as well as a new flip-top cap-closing system. The latter uses a lightweight carbon-fiber robot arm that captures, verifies, and closes the flip-top caps on the fly, faster than with free drop. With this approach, each parting line opens about 4 in. Not dropping the parts avoids damage to highly polished part surfaces, allows parts to be ejected hotter, ensures that parts shrink against their mating surfaces, and eliminates need for unscramblers. The new system has been used on up to 128 cavities in a 2x64 stack mold.

As reported in March, speed enhancements are touted for YC and YCII side-entry models from Yushin America, which replace the “value-priced” YA and YAII models.

Also new at the show was the 811 G side-entry robot from Sytrama USA. Sytrama recently was recently acquired by the Sacmi Group, which includes Negri Bossi. That move resulted in greatly increased inventory of robots and spare parts in North America, as well as an expanded service and support staff.

SMARTER TOP-ENTRY MODELS

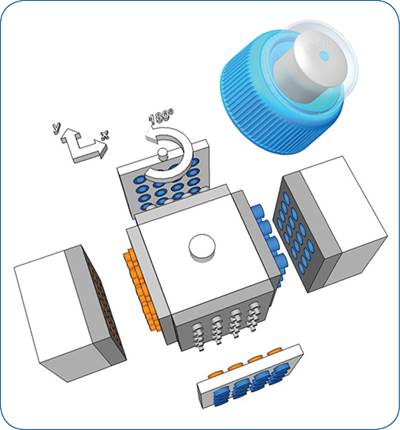

Improved controls and programming were attractions of several new top-entry Cartesian robots. As reported in March, Wittmann Battenfeld has added a number of new software routines to its latest R8.2 robot controller. And the new Visual 3 control for the newest S5 line of robots from Sepro America reportedly can cut part-removal times by 10% with a new “flying-start” function that anticipates the end of each molding cycle and starts the robot moving even before the mold opens. Its PLC processor runs at 20-millisec speeds, five times faster than its predecessor. Visual 3 can also work with intelligent sensors so as to recognize different grippers with an RFID reader or use vision systems for QC or part positioning. The robot can coordinate with any moving object, such as a conveyor.

Several former options—such as a digital vacuum switch—are now standard. A new option allows “path tracking”—programming several points along a path for complex motions inside or outside the mold.

Other news from Sepro includes the smallest model in the S5 series (S5-15, reported in March) and the brand-new Success 22 line of economical three-axis servo robots. Five new models replace the three in the former Access 22 series; common subassemblies help achieve economies of scale and reduce lead times. Designed for machines from 150 to 400 tons, Success 22 models can handle 25% heavier payloads (up to 22 lb standard) and the 27.5-in. strip stroke is 8% longer than the previous maximum. Speeds on all axes have been increased by 20% or more.

Other features, some usually available only on more expensive robots, include simultaneous motion of all three axes, compact beam-mounted control cabinet to save floorspace, and optional pneumatic R2 wrist rotation. Stroke lengths are 79 in. horizontal and 55 in. vertical, which can be extended to 63 in. with an optional telescoping arm.

Sailor Automation also introduced an economical new “entry-level” line of servo robots, the RZ-X series. All axes use rack-and-pinion direct drive instead of belts that can stretch. Takeout dry cycle is less than 1 sec and overall dry cycle is less than 6 sec. A 90° wrist turn is standard. They offer single or double arms and a pendant controller with 3.5-in. touchscreen. Also new are remote support and troubleshooting services. For higher speed, Sailor also introduced the RZ-ΣII series, the company’s new standard line for presses of 110 to 1300 tons. These also have rack-and-pinion drives and single or dual arm, but with takeout dry cycle less than 0.8 sec and overall dry cycle less than 5 sec. The upgraded control pendant has a 7-in. color touchscreen.

New from Sytrama is the 251G Series of servo robots, which fills a gap between the smaller 201G and the larger 301G, offering strokes similar to the larger unit but with slightly lower payload capacity (88 lb) and lower cost. Suited to presses from 1200 to 3000 tons, they use the recently upgraded SCP color touchscreen control pendant.

Wittmann introduced to the U.S. a new model in its 8 series of servo robots, which uses the latest R8.2 controller. The small W818 carries up to 6 kg and has a vertical stroke up to 1200 mm. It has absolute encoders on all three servo axes and can accommodate optional B and C servo wrist axes.

Also new is the revamped large W831 model for presses up to 500 tons. Its payload capacity has been upped from 22 to 26.4 lb for a Y axis of 1200 mm or less (up to 1400 mm is available). Horizontal stroke starts at 2000 mm standard and can be extended to 5000 mm to allow an “L” configuration with clamp-end placement of parts.

Other new entries—previewed in March—were two robots and a sprue picker from Star Automation , the new Viper 12 from Engel Machinery, a variety of automation solutions from Waldorf Technik, and the “ultra-high-speed” HSA robot from Yushin America.

Yudo Inc., best known in North America for its hot runners, aims to raise the profile of its wide range of auxiliary equipment, including robots sold under the Yudo-Star brand (a joint venture of Yudo in Korea and Star Seiki in Japan). These include a wide range of traversing robots, swing-arm pickers, and even six-axis robots for applications including automotive, optical equipment, cell phones, home electronics, and IML.

NEW JOINTED-ARM ROBOTS

As reported in March , both Arburg and Engel highlighted their integration of six-axis robots with their injection machine controls to make programming easier. Also reported previously, one of the fastest new robots at NPE was Staubli’s TP80 four-axis picker.

In addition, Kuka Robotics Corp. showed off its new KR Quantec K shelf-mounted, six-axis robots. They are about 12% lighter than previous models, making them easier to mount on injection machines. The extremely low base extends the robot’s reach downward for unloading presses. New C4 controls and drives are said to provide 25% faster unloading. The new controls are based on industry-standard rather than proprietary architecture and include Ethernet-type connectivity.

Two versions are offered: Quantec K Prime for payloads from 90 to 210 kg and Quantec K ultra for payloads up to 270 kg.

NEW EOAT

The lastest robot tooling developments from SAS Automation include the GSZ spring-loaded sprue plier arm, high-heat “markless” vacuum cups, and pneumatic two-finger parallel grippers (all previewed in March). Other developments over the past year or so include the QSR/QST semiautomatic tool changer; a machine-mounted, heated sprue cutter; two-sided manual deburring knives; a wide range of internal diameter grippers (IDG) for very small to very large or fragile parts; and spring-loaded docking pins for insert molding. In addition, SAS showed a complete new insert-molding cell integrated with the robot controller, so there’s no need for a separate PLC. Features include a safety light curtain, tapered interlocks that positively locate the EOAT for precise positioning of the insert, and part verification with a photoelectric sensor.

FIPA Inc., the U.S. branch of FIPA GmbH, showed off a variety of custom EOAT solutions. New products include a miniature rotary unit, slightly bigger than a matchbox and weighing just 3 oz; three-finger grippers and grippers for particularly long strokes; and lightweight expansion grippers to grip objects from inside.

Several introductions from the Eins tooling dept. of Star Automation include a quick chuck-change tool with magnetic hanger for fast, automatic tool changes, as well as a manual quick-change version. Also new or redesigned are magnetic grippers, mini air nippers, and rough-surface suction pads and dual-surface cups for parts with holes. A new I/O communication unit can send and receive up to 32 signals on just two wires.

Yushin has re-engineered and optimized its EOAT, cutting the weight by up to 40% and reducing vibration, both of which reportedly help cut cycle times by 10%.

Related Content

Drones and Injection Molding Ready for Takeoff

Drones and unmanned aerial vehicles (UAV) are approaching an inflection point where their production volumes — and functionality — will increasingly point to injection molding.

Read MoreReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreEnsuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

Read MoreSystem Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

Read MoreRead Next

TOOLING AT NPE: Hot Runners & Coinjection Grab Spotlight

Tooling innovations at NPE focused primarily on multi-cavity closure and medical applications, though there was also a substantial emphasis on large automotive and appliance parts.

Read MoreNPE: New Machines Exhibit Sophisticated Molding Demos

More speed, more power, more precision, and more automated functions accomplished in and out of the mold. That’s exactly what injection machinery suppliers were offering at NPE2012.

Read MoreInjection Molding: Speed, Automation & Integration

Hot buttons at the show will be multi-component molding, in-mold labeling/decorating (IML/IMD), in-mold assembly, medical molding, liquid silicone rubber (LSR), micro-molding, and high-speed packaging.

Read More

.png;maxWidth=300;quality=90)