Robots Play a Role in Industry 4.0

Robots are gaining the ability to monitor their internal systems for remote troubleshooting and predictive maintenance. They also are reporting production data.

If a show as big as NPE can be said to have a single overarching theme, this year the leading contender would be the wave of technological innovation and futuristic enthusiasm known variously as Industry 4.0 or the Smart Factory or the Internet of Things. That wave has charged across the ocean from Europe, where new protocols for machine-to-machine and machine-to-central-computer communications are being developed under the leadership of the German machinery association, or VDMA, as well as the European Plastics & Rubber Machinery Association, EUROMAP.

Although much of plastics machinery used here comes from Europe, the concept of Industry 4.0 has not achieved the same degree of familiarity on this side of the Atlantic. “Molders here are more at the stage of ‘What is it, and why do I need it?’ They want to know how much change it will bring to their operations, what it will cost, and how they will benefit,” says David Preusse, president of Wittmann Battenfeld, Inc.

Jim Healy, v.p. of sales and marketing for Sepro America, thinks that Industry 4.0 can be understood in part as an evolution of trends that have been developing for years. “If Industry 4.0 is about connectivity between machines, then robots have been ‘Industry 4.0’ for years, thanks to standardized control protocols. Today, that connectivity goes several steps further in automation cells that may involve not only a molding machine and a robot, but also insert feeders, secondary robots, complex end-of-arm tooling, in-mold sensors or vision systems, post-mold handling, inspection, finishing, stacking, and packing.”

Preusse advises show visitors to observe how exhibitors illustrate practical ways of using elements that tie into this new Smart Factories era. He said these can include:

• Molding cells with robot, press, and auxiliaries all connected together;

• Mold setup recipes for robots and other auxiliaries stored on the injection machine for

faster mold changes;

• Web service support;

• MES collection of production data;

• Smartphone apps to get production status or alerts;

• Predictive-maintenance monitoring of robots and other cell equipment;

• “Smart molding” process solutions;

• Production traceability;

• Remote access and control.

That’s an awful lot to digest, and Chris Parrillo, national sales manager of Yushin America, thinks the best way for molders—especially those from small to mid-sized firms—to approach the topic is to “break it down into manageable chunks.”

One of those chunks is predictive maintenance, which is an emerging theme that is being sounded at the show by injection machine suppliers and builders of auxiliary equipment. The idea is for a robot “to monitor its own internal systems and detect problems as they develop, so it can warn of a maintenance issue before a catastrophe strikes on a weekend shift,” explains Dino Caparco, Yushin’s engineering operations manager.

Some of early signs of this trend for robots are visible at NPE. For example, look for features such as monitoring gripper vacuum levels to warn of leaks or other problems before the robot loses its grip. Other approaches include vibration sensing and monitoring servomotor torque and amperage load to detect bearing misalignment, insufficient lubrication, damaged rails, and/or fatigue of the robot arm due to repeated flexing.

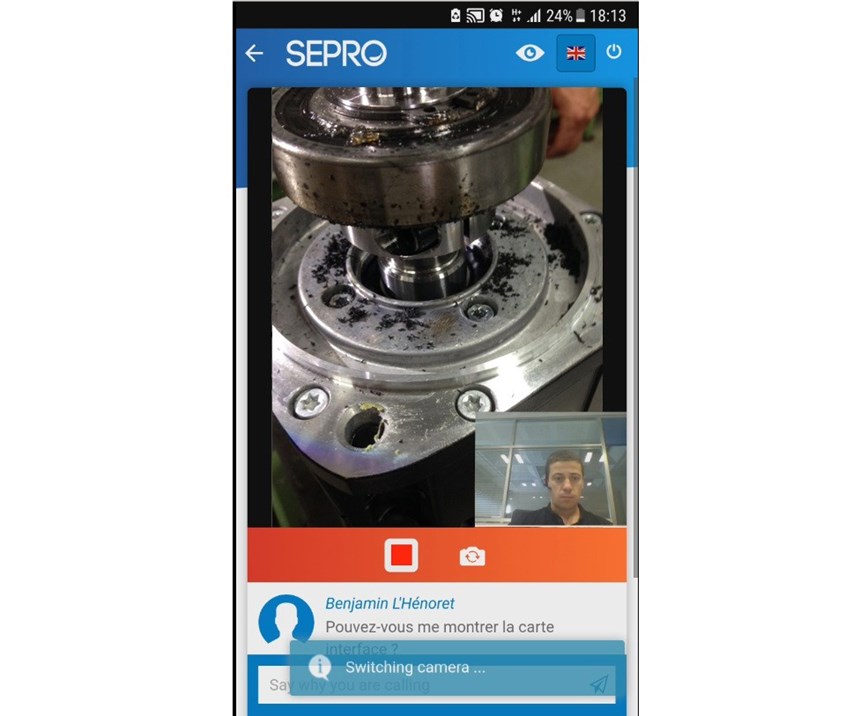

Another closely related “chunk” of Industry 4.0 is remote monitoring and web-service support. Such features have become increasingly common for molding machines and are now spreading to robots.

Still another related trend under the broad umbrella of Industry 4.0 is varying degrees of integration of robot controls with those of the injection press, which can range from “mirroring” of the robot control interface on the operator panel of the press to actual sharing of data between the robot and press—a more complex issue when different vendors are involved.

Related Content

Are Your Sprue or Parts Sticking? Here Are Some Solutions

When a sprue or part sticks, the result of trying to unstick it is often more scratches or undercuts, making the problem worse and the fix more costly. Here’s how to set up a proper procedure for this sticky wicket.

Read MoreHow to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

Read MoreHow to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

Read MoreHow to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More

.png;maxWidth=300;quality=90)