Rogan Corp. Is an Old Hand At Exploring New Frontiers in Plastics

On Site

the 78-year history of the Rogan Corp. is full of twists and turns. But one consistent theme stands out—an adventurous and inventive spirit that has put Rogan on the leading edge of a number of important trends in plastics—and even on the frontiers of space exploration.

From compression molding phenolic knobs and dials to overmolding liquid silicone rubber onto metal and thermoplastics, the 78-year history of the Rogan Corp. is full of twists and turns—what chairman Edward Rogan calls “transformations” in his decade-by-decade narration on the company’s website (rogancorp.com). But one consistent theme stands out—an adventurous and inventive spirit that has put Rogan on the leading edge of a number of important trends in plastics—and even on the frontiers of space exploration.

Today, Rogan Corp. is a $10-million business with some 65 employees in a 45,000-ft2 plant in Northbrook, Ill. Rogan specializes in liquid silicone (LSR), two-shot, and insert molding for medical, electronic, aerospace, telecommunications, appliance, lawn/garden, and sports/recreation industries. But while it is pursuing some of the hottest areas of injection molding innovation, Rogan also remains tied to its roots.

The three Rogan brothers left Winnipeg, Manitoba, in 1927 to seek their fortune in Chicago. They founded Rogan Brothers Co. in 1934, providing calligraphy services to retailers, schools, and churches. They broke into plastics in 1937—on a wager. A business acquaintance bet Nick Rogan a fifth of whiskey that he couldn’t invent a process for decorative marking on plastics. By 4:00 AM the next morning, Nick had come up with a “branding” technique that family legend holds to be the origin of what is now called hot stamping.

The appliance industry eagerly embraced this new method for decorating plastic knobs and dials as a replacement for time-consuming engraving and “paint-and-wipe” methods. Throughout the 1930s and ’40s, Rogan Brothers thrived in marking plastic knobs and military equipment, such as dials for gun turrets.

In 1946, the company acquired three war-surplus compression molding presses and began making its own phenolic knobs and dials. Ed Rogan II, son of one of the founders (and now the sole owner), joined the family enterprise in 1949 at six years old, earning a Chicago Cubs game ticket for inserting 5000 screws in a 6-hr shift, doubtless violating all sorts of child-labor laws by today’s standards.

In 1967, the firm bought its first injection machines and began insert molding plastic over metal. In 1969, Rogan Corp. received a commendation from the U.S. government for its contribution to the first moon landing. “We believe we had a knob on the instruments that collected or analyzed moon rocks,” Ed Rogan explains.

In 1982, Rogan pioneered the new field of multi-material or two-shot injection. This led to hard/soft overmolding of TPE onto rigid thermoplastics—another headstart in what is now a booming specialty. In 1991, Rogan was one of the early practitioners of gas-assist molding. The latest “transformation” was Rogan’s 2006 entry into liquid silicone—jumping right into overmolding LSR onto stainless steel and polycarbonate (PC). And just this year, the company built a Class 100,000 clean room to house its four horizontal and vertical LSR presses.

Today’s Rogan Corp. is a mix of old and new. Dials and knobs remain 65% of its business. Three thermoset compression molding presses still get some use. “We’ve been making some of these products for as long as 40 years,” says Operations director Jim Ritzema. “They still pay the bills.”

FOCUS ON LSR & TWO-SHOT

Today, two-shot molding is around 40% of Rogan’s business (including some dial and knob applications), and nine of its 34 thermoplastic presses have two-shot capability.

LSR accounts for only about 10% of Rogan’s current sales, but that share could soon double, because 40-50% of its new business is in LSR, says Robert Flammini, v.p. of sales and marketing. “LSR and two-shot molding are the areas we want to grow in,” says Ritzema. “We don’t want to compete in commodity molding.”

Medical is Rogan’s main growth target. It accounts for the installation of the company’s first “hard” clean room, with 1500 ft2 devoted entirely to LSR molding and assembly. Previously, Rogan used some portable, soft-sided clean-room machine enclosures and may use them again, though it is already planning a Phase II expansion of the permanent clean room.

LSR is the key to its medical market focus. “LSR can be autoclaved,” notes Ritzema. “It has low compression set, and its flexibility allows it to be demolded from large undercuts on both cavity and core sides.”

“We began strategic planning for an entry into LSR in 2003,” recalls Ed Rogan. “That was just after the SARS epidemic hit. We saw the trend in hospitals to replace devices in contact with patients more frequently, such as every eight hours instead of once a day. That made it more economical to purchase more costly but re-sterilizeable components instead of disposables.”

Rogan started out in LSR with a Nissei press but now prefers Sodick Plustech machines because it finds their V-Line two-stage screw/plunger injection system to be more precise, since there’s no check valve to leak. One of its presses is a 150-tonner, which is on the large side for LSR. The Sodick machines are electric/hydraulic hybrids, but Rogan may look into all-electrics in the future. Rogan uses LSR mixing/metering systems from Fluid Automation, Inc. While Rogan works with several moldmakers that specialize in LSR (M.R. Mold, Kingson Mold, and Roembke), Rogan uses its own cold-deck design. All its LSR molds use cold runners to avoid discarding cured waste that costs $8 to $13/lb.

Rogan quickly became expert at molding LSR with very tight tolerances and difficult shapes. “Customers are always pushing the limits,” says Ritzema. “They ask us, ‘How thin can you go?’ We have molded a 4-mil LSR bottom onto the PC rim of a petri dish 3 inches in diameter,” says Ritzema. “We can hold half a mil tolerance on an 8-mil-thick diaphragm that’s overmolded onto a PC rim. We’re also one of the few firms with experience in molding optical-grade LSR.”

Right from the start, Rogan jumped into LSR overmolding onto stainless steel and thermoplastics like PC, PC/ABS, nylon, PBT, and Ultem polyetherimide (PEI). At present, all such jobs involve insert overmolding the thermoplastic or metal component, though true two-shot thermoplastic/LSR molding is the logical next step for high-volume jobs. The company is even looking into two-shot LSR-on-LSR molding. “It’s not easy to do soft on soft,” cautions Ritzema. “Shutting off steel on a soft material is tricky.”

One of Rogan’s customers is developing a home dialysis device that is PC with eight small TPE bladder inserts. These are overmolded at present but eventually will be in two-shot production.

Another LSR overmolded part is a medical device (cervical seal) consisting of a section of thin PC tubing with 5-6 mil LSR fins molded onto it. Another part (lung catheter) is a 30-in.-long tube of Pebax TP elastomer from Arkema with an LSR finned “bumper” molded onto the end. A tiny button-sized device that is actually a miniature microphone consists of stainless steel and Ultem encapsulated in LSR. Another developmental medical part (arterial shunt) consists of a stainless-steel spring overmolded with two separate shots of LSR.

The key to Rogan’s success in LSR overmolding has been the arrival of “bondable” silicones that adhere well to thermoplastics. Rogan has formed a close relationship with its main LSR material supplier, Shin-Etsu Silicones, which has helped it deal with adhesion issues. Though bondable LSR works well with thermoplastics, there still can be occasional problems. In one case, Rogan was buying a polycarbonate part from another molder and found that overmolded LSR was not adhering as expected. The culprit turned out to be mold release on the PC part.

Meanwhile, LSR adhesion to metal “still has a ways to go,” in Ritzema’s opinion, “especially for small parts with little surface area to bond to. We’ve tried primers. We’ve tried plasma treating metal, but it didn’t help.”

The other arm of Rogan’s growth strategy is two-shot molding. “We were pushed into it by one of our biggest customers,” says executive v.p. David Schoessow, who has been with the company for 34 years. “They wanted soft-touch knobs. We did two-shot even before we had tried insert overmolding.”

An example of two-shot, hard/soft molding is a child’s dinnerware set of PP and TPE. Another is a smartphone cover of TPU molded on TPU—two colors and durometers—with an insert of a thin PC ring for the phone’s camera window. What’s notable about these parts is that they are both examples of “reshoring” jobs that had been outsourced to China. They came back here because of issues with quality and logistics—transportation time and cost, according to Ritzema. “We’re even shipping some parts to China,” he adds. That’s because medical OEMs are more comfortable with domestic manufacture.

Rogan buys Sumitomo Demag presses for one- and two-shot thermoplastic molding. “Without experience in this field, it’s hard to buy a two-shot machine,” says Ritzema. There really is no ‘general-purpose’ model. A lot of two-shot jobs are very specific, and there are so many different types of machine and tooling design. You could spend $500,000 on a machine that might not work for half the jobs out there.”

Rogan gains an edge in two-shot molding from its proprietary mold designs. Explains Ritzema, “We have hundreds of modular mold bases that allow us to load cavity and core inserts for different jobs from the mold face. It adds flexibility and reduces tooling cost. We also have a proprietary rotating mold base.”

LOOKING AHEAD

“We want to get bigger in contract manufacturing,” says Bob Flammini. “OEMs want a single supplier for a full turnkey package. We can supply molding and pad printing, hot stamping, heat staking, ultrasonic welding, kitting, and packaging. We want to be a total solution provider.”

“We’re building up our design capability,” adds Ritzema. “We already understand design for manufacturability, and we can evaluate customers’ designs for potential tooling, molding, and assembly problems. We help to design for automation where possible.” This knowledge is especially vital in LSR jobs. “Few customers understand LSR design. They don’t realize how it can flash through half a mil gap.”

“We’re bidding on bigger jobs now,” says Flammini, “so we’re looking at bigger machines for more cavities.” Rogan wants to go smaller, too. It has ordered a 20-ton Sodick press with a 14-gram shot capacity to mold smaller thermoplastic parts.

While pinning much of its growth strategy on LSR, Rogan acknowledges that competition is growing in this area. Ritzema thinks the LSR market is expanding enough to accommodate new players. “The greatest difficulty in getting started in LSR,” he says, is finding experienced people. Until recently there were no school programs for LSR engineering.”

How does Rogan keep abreast of this fast-moving area of technology? Ritzema responds, “We read, go to seminars, do as much investigating as possible. We discovered Sodick at a trade show. And we have learned a lot from the LSR materials people, who helped us through a lot of adhesion problems.”

Related Content

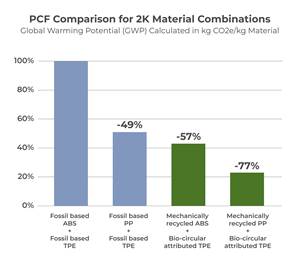

More Sustainable Two-Component Overmolding

Swedish compounders HEXPOL TPE AB and Polykemi AB have collaborated on a 2K sustainable development project for consumer products.

Read MoreVideo: Ultradent Bags Both Hot Shots Prizes at PTXPO 2023

Topping five other entries in voting by fellow molders, the Ultradent team talks about their Hot Shots sweep.

Read MoreLarger Capacity Auxiliary Injection Unit Introduced

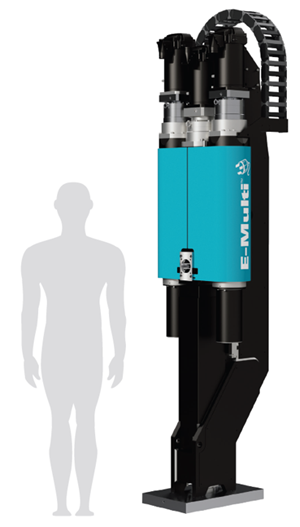

Mold-Masters has extended the capabilities of its E-Multi auxiliary injection platform, introducing the new larger capacity EM5 model.

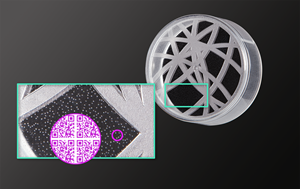

Read MoreMold, Hot Runner, Digitization and Process Monitoring at K 2022

The Barnes Group’s Molding Solutions division companies will highlight new mold and hot runner technologies at its own booth and at several machinery partners during K 2022.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More

.png;maxWidth=300;quality=90)