Service & Response Drive Growth of Custom Compounder

Lanier Color has experienced an eightfold increase in business since 2000. Its focus on technical support and customer service help explain why.

When John Cothron went to work for Lanier Color Co. back in 2000, the custom compounder was just four years old. It had two production lines, a small lab line, and about $3 million in sales.

Some 16 years later, the Gainesville, Ga., firm has seven production lines, runs 24:5 out of a new 40,000 ft2 plant, employs about 75, and has annual sales of more than $25 million. It has grown by double digits just about every year since 2000—in some years by 20%—save for a flat period in 2009-2010 during the housing crunch, which is pretty astonishing in itself, considering that a lot of its customers are profile and sheet extrusion processors that serve the building and construction market with siding, window lineals, base moldings, and bathroom partitions. “We run a wide range of materials, but the majority of what goes through here is flexible or rigid PVC,” Cothron states.

Lanier was formed in 1996 by Timm Scott and two partners. Scott’s background was color; he worked for PMS Consolidated, a leading global color compounder (now part of PolyOne). Timm Scott’s son Dan is Lanier’s manufacturing manager. Scott and his partners sold Lanier in 2014 to Cothron, now company president, and three other employees: Greg Walby, dir. of business development; Selwyn Glanzer, v.p. sales; and Blake Johnson, technical director.

In his 30-yr career, Cothron has worked in color, tool and die making, and injection molding. His first mission at Lanier was to put together operating systems for inventory management, order taking, production, and more. He wrote the software, which was fully operational by 2003. Lanier has since hired a programmer to add functionality to these homemade systems to make them “more robust.” For a business that does up to 25 product changeovers a day, these systems are critical to helping Lanier pivot quickly from one job to the next. “You need to be able to generate order entry and inventory allocation at a press of a button to initiate any quick-change process,” Cothron says. “We also try not to be capacity limited at any time so we’ll have more flexibility to jump from foot to foot quickly.”

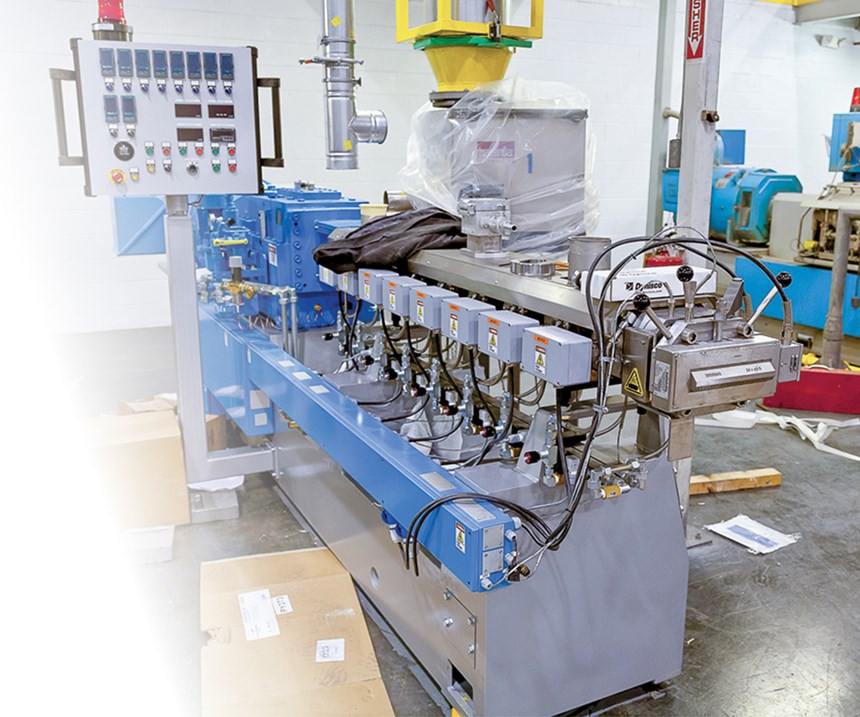

Lanier stages its production runs on seven twin-screw corotating compounding extruders from Leistritz, Somerville, N.J., so that most of its product changes involve purges and cleandowns; Lanier pulls screws and changes elements only about 10-15% of the time. The Leistritz lines range in size from 27 to 75 mm, including an older 27-mm for lab work. Lanier runs at a wide range of outputs from 40 to 5000 lb/hr. The firm purchases the extruders alone from Leistritz rather than buying a turnkey system with upstream feeding and pelletizing systems. “Our preference is to engineer the system ourselves because we like to think we understand our applications better than our suppliers,” says Cothron.

“We get great technology and support from Leistritz and other equipment suppliers, but I doubt they are thinking of Lanier Color’s application when designing their next extruder. They are looking primarily at throughput. We are looking for throughput too, of course, but our primary goal is dispersion and distribution in heavily loaded compounds. So our needs are a little different.” Lanier uses feeding and blending systems from Brabender Technologie Inc., Mississauga, Ont.; and scales, loading, and materials-handling systems from Tech-Weigh, Griffith, Ind. Lanier uses primarily strand pelletizing technology from Berlyn ECM, Worcester, Mass.

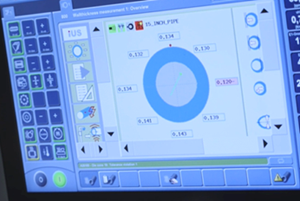

Lanier separates its mixing and extrusion operations. During extrusion, it pulls products off-line for quality-control checks on lot-to-lot color control and pellet-size consistency. Samples and originals are compared for quality assurance, and products are tested for regulatory compliance when required.

THE SERVICE MANTRA

In the world of color, Cothron says, quality has become “a given.” He elaborates, “We’re all using the same raw materials from the same boxes, etc.” So how does this explain Lanier’s rapid growth in Cothron’s tenure? Service and response time, he replies. “The way we differentiate is through service. That’s our mantra. We work with customers to help them with speed to market; as they get opportunities and develop new products, the quicker they can get products to market the better.”

In one real-world example, Cothron recalls the time a customer had a “unique opportunity” to bring a new product to market for one of its clients, but the time frame it had to capitalize on this opportunity was short. They called Lanier. “At about 8:30 am we took color and their polymer, performed a match, and they had 1000 lb by 4:00 pm. They were making their product and getting it to their customer the next day.”

Cothron continues, “But service and response covers a lot of different things. Sometimes a customer will run out of product. We quote 7-10 working days’ lead time, but we’re typically at a 4-5 working day range. That leaves us some flexibility so if someone needs something in an emergency, more often than not we can take care of it.”

TECHNICALLY SAVVY

This kind of philosophy has helped Lanier pick up market share from competitors over the years. Sometimes this has been at the expense of larger companies that might be less nimble than Lanier. But as Cothron sees it, a better explanation is in Lanier’s commitment to formulating a product that fills a need or solves a problem. He states, “As companies grow they tend to get more rigid in their operation. What began as a primary focus for a company can change significantly. Lanier strives to maintain flexibility as we grow, and we were established on the principle of ‘focus on the customer.’ So to some extent we have gained market share as a result of those principles, but we’ve also gained through helping customers achieve a technical advantage with their products.”

Cothron says his experience in molding helped him sharpen Lanier’s tech-support efforts. He explains, “In my first experience in molding, we were running PE at 600 F. Why? Because I didn’t know any differently. When that worked it was only because we were running at extremely fast cycles. But that’s typically not what we see in the market. So if you are designing a product for an application, you have to understand things such as heat stability, weatherability, FDA regulations.

“We do our best not to suggest or dictate process parameters to a customer,” Cothron adds. “However if a customer runs into a technical issue that’s process related, we’ll help if we can. Most of our technical service is related to a customer that wants a product that does “X” to the extent we can we design and formulate a product to accomplish what they are trying to achieve. Heat stability is a big issue now. We have technology that allows us to get dark colors that don’t absorb the kind of heat that you would typically see.

“At first, customers would come to us looking for speed and response at first, in order for them to grow. But in other cases we’ve solved a technical issue or offered a fresh solution to a problem. It’s usually not price or minimum order size that drives customers to us. There is a need that’s presented and you try to meet it. Customers know what they need and know what their struggles are. They might know they’d be better off if they had “X.” So how do you provide X? You make yourself easy to do business with and give the customer what they are looking for. ”

While Lanier was founded as a color house and still primarily focuses on that area, it also does specialty compounds with specialty additives, UV stabilizers, flame retardants, and antistatic agents for products that have no color in them at all. “Far more often, we find products in the market that are under-engineered,” Cothron says. “Parts are fading and distorting because they are absorbing too much heat. But if you know the answer and know how to fix the issue, you’ve got something to talk about.”

Pigment selection is one way to minimize heat buildup in decking, fencing, or windows, Cothron elaborates. Another is the interrelationships between pigments. “You can take two pigments that perform very well on their own and when you put them together they are terrible. Or you can take two pigments that don’t perform well on their own and when you put them together it looks pretty decent. How do you get a black that doesn’t get too hot? You have to be pretty creative.”

Technical acumen aside, Cothron believes color matching is equal parts art and science. “I’ve heard some people say that color is entirely science. But in reality, until you can take all of that science and put it in a box and feed it into a spectrophotometer and have it read a standard and spit out an answer at the other end, there will be art involved. A customer will come to us and want a gold or chrome-plating look without the gold or chrome. You can’t duplicate that with color. But, the art is getting as close to it as you can. How do you minimize heat buildup and retain weathering resistance? How do you go into the market with an orange that is going to have exterior exposure but is going to perform like the brown and tan that you more typically see? Let’s just say the business of color is a lot of art backed up by science.”

Related Content

Fully Automated Extrusion Process Enables Use of Composites for Manufacturing Pressure Tanks

Amtrol was looking for a more cost-effective means to produce thin-wall liners for a new line of pressure tanks. With the help of a team of suppliers, they built one of the world’s most sophisticated extrusion lines.

Read MoreCooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

Read MoreUnderstanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read MoreAvoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More