K 2016 Extrusion: Speed, Versatility Rule the Day at K

Shorter product runs mean frequent product changeovers for processors, and suppliers responded to these trends across all extrusion technologies.

Two themes resonated in extrusion during October’s K 2016 show in Dusseldorf: speed and flexibility. This was in evidence across all types of extrusion, on complete lines as well as in key components as suppliers try to respond to processor needs for more throughput and faster product changeovers.

This article summarizes these developments not previously covered in Plastics Technology’s September’s K 2016 preview.

MORE FLEXIBILITY IN FILM, SHEET

In blown film, orders are getting smaller and smaller, which means the quicker a processor can shift from one to the next, the better. Windmoeller & Hoelscher Corp. showed a system aimed to address that need. Called Turboclean, the system ran on a five-layer Varex II line making collation film. Introduced last June (see August Close-Up), Turboclean is a lightning-quick product-changeover technology that permits blown film processors to make complete format changes—material, color, thickness, layflat width, web tension, blow-up ratio, etc.—in a couple of minutes. Typically this is at least a half-hour process.

W&H also operated a three-layer Optimex line producing lamination film for stand-up pouches. This film is typically made at thickness of 80 microns; the line W&H ran was 60 microns thick. Meantime, at its Lengerich headquarters, W&H ran a Filmex 13-layer cast barrier-film line furnished with the firm’s newly developed Film Performance Monitor (FPM). FPM integrates data from the extrusion line with downstream converting equipment, allowing these two previously discrete operations to be networked to improve quality and make the entire production process seamless.

Hosokawa Alpine American (Natick, Mass.) is believed to have set a record by running the most layers on a blown film line at a K Show. At K 2016, the company operated an 11-layer barrier-film line designed for maximum flexibility. The line featured 11, 65-mm, 30:1 L/D grooved-feed extruders with water- cooled extruders and main drives. It was equipped with Alpine’s 560-mm X die and a height-adjustable V air ring.

Alpine changed structures regularly to show the line’s flexibility, running EVOH and nylon as a barrier along with tie layers and various grades of PE. Most machine builders avoid running nylon at trade shows due to its tendency to form gels, but Alpine says the streamlined X die eliminates the hang-ups and dead spots that spawn gels. Alpine officials called the line “infinitely flexible” in that it permits processors to mix and match layers and materials in a wide variety of combinations.

Among major blown film line components, Addex Inc., USA launched a new air ring that incorporates the company’s new Intensive Cooling Experience (ICE) technology in a dual-flow configuration. The dual-flow air ring reportedly delivers 10-15% greater output and better bubble stability than competitive offerings, says Addex, Newark, N.Y.

The ICE technology (see June ’16 Close-Up) utilizes four stacked cooling elements with a surrounding enclosure, all topped by a conventional air ring. But what Addex showed at K 2016 is a scaled-down version suited for retrofits; it uses only a single cooling element combined with Addex’s original dual-flow air ring.

Instead of using a manifold to split up chilled air, the new Vector air ring from Brampton Engineering Inc., Brampton, Ont., is made with a single inlet precisely contoured to generate uniform air velocities around the bubble. This reportedly provides higher throughputs, lower pressure losses, and more repeatable setups. Flow variations with the Vector are ±0.6%, compared with ±2.25% typically seen in six-inlet air rings, says Brampton.

In flat film news, Italy’s Amut ran the ADB Power stretch line at a speed of 3280 ft/min. The 7-layer, 4-up line ran 13 ft wide, producing hand and machine stretch film at an output rate greater than 3500 lb/hr. The line featured six extruders with what Amut says is a unique 40:1 L/D for low energy consumption.

In sheet, PTi/Processing Technologies International, Aurora, Ill., has granted Nordson Extrusion Dies Industries LLC, Chippewa Falls, Wis. an exclusive license to manufacture PTi’s patented FastSe-LECT system, a novel Layer Exchange Conversion Technology that achieves virtually instantaneous color changes within the coextrusion process.

FastSe-LECT technology is said to improve efficiency by reducing operating costs, regrind generation, and lost production days. It allows processors to quickly change the layer positions of extrudates from two extruders in a coextruded structure without tedious disassembly and costly shutdowns.

Color changes can be made in seconds; conventional methods requiring purging times that can take 30-45 min. By changing the diverter piston position via a manual lever while the machine continues to run at full rate, the color- layer positions are swapped between the “old” color layer and the “new” color layer, with the “old” color layer being re-directed to the core for continuous purging and setup for the next “new” color.

The FastSe-LECT diverter valve features a proprietary piston, which is moveable in a stationary body. The body has two entrances that feed from separate extruders. The first position of the valve allows the material to enter the piston flow channels and permits a flow-through pathway. Normally, this would produce an A-B structure. When the alternate position is selected, the materials are routed through alternate flow paths that exchange the extrudate positions, producing a B-A structure.

MORE VERSATILE COMPOUNDING

In compounding news, Coperion Corporation (U.S. office in Pitman, N.J.) displayed the STS Mc11 series launched in 2015. With a maximum specific torque of 11.3 Nm/cm3, the twin-screw co-rotating machine is engineered for compounding jobs that require a higher energy input. Users benefit from the screw flight’s increased fill factor and the related high throughput rate at a reduced melt temperature. Designed for masterbatch production, the machine displayed at K 2016 had a new feed hopper and a reworked die head, plus other enhancements that reduce the time for cleaning and material changeovers.

Coperion also displayed the ZSK Mc18 twin-screw extruder series with a maximum specific torque of 18 Nm/cm3. The machine has been redesigned to reduce its footprint and also features a new control cabinet design. Downstream, Coperion launched the UG 750W underwater pelletizer, which offers throughput rates of 60-70 tons/hr to fill the gap between its medium-output range (55 tons/hr) and its much larger (82 tons/hr) pelletizers.

Leistritz (Somerville, N.J.) showed several new machines. Designed primarily for masterbatch production, the ZSE iMaxx has been designed with easy-to-clean surfaces. A stainless-steel cover protects the processing and drive unit from accidental contact or contamination. Cooling/heating devices are fully integrated into the machine frame, making them easy to access for cleaning and maintenance. The machine can also be quickly and easily extended from 24:1 to 48:1 L/D as required by formulation changes. Add-on modules like side feeders can be mounted on either side of the machine.

Meantime, Leistritz had on display the largest machine it’s ever built: the ZSE 260 Maxx with a drive power of nearly 9500 kW (12,730 hp), a screw torque of about 112,500 Nm, and throughputs to 35 tons/hr. A high OD/ID ratio of 1.66 is said to offer a broad processing window while providing good energy input.

FARREL POMINI, Ansonia, Conn., introduced a new Compact Processor at K 2016. Called CPeX, the Laboratory Compact Processor, this machine is suited to lot sizes of 22 to 66 lb/hr. The CPeX is for masterbatches and compounds of temperature-sensitive, highly abrasive materials requiring intensive mixing at low processing temperature.

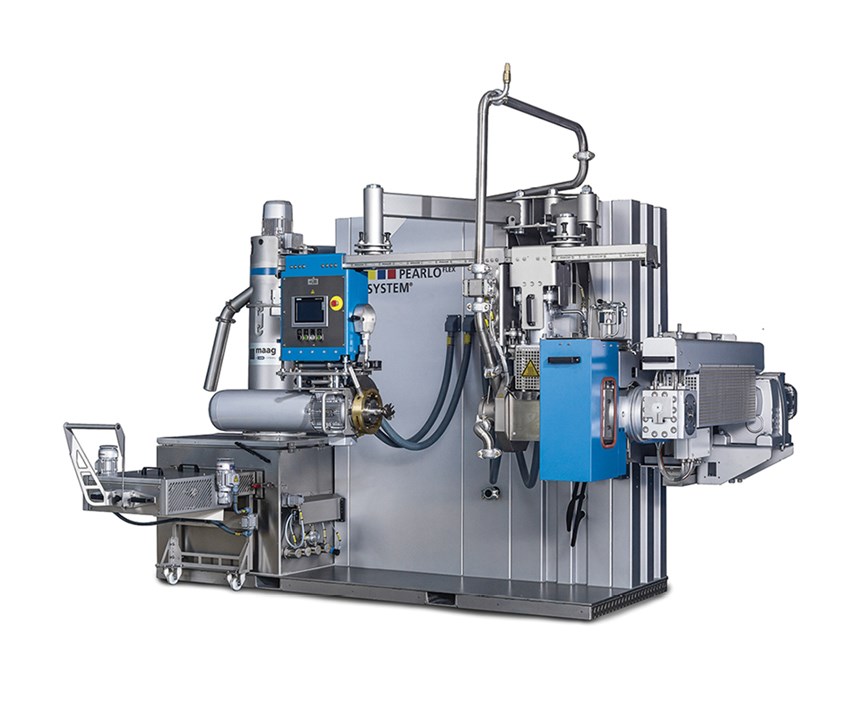

The new Pearlo underwater pelletizer from Maag Automatik, Inc. (Charlotte, N.C.) is designed to run at up to 79,200 lb/hr. Maag also showed the Puro tempered process-water system for both strand and underwater pelletizing. With outputs ranging from 154 lb to 79,400 lb/hr, Puro is a closed- loop water system with several integrated filtration options; it conveys and cools pellets between the pelletizer cutting chamber and the centrifugal dryer. The system is compatible with a wide array of polymers.

Maag’s new Cyclo centrifugal pellet dryer is designed for a wide range of polymers at rates from 6600 to 18,700 lb/hr. Compact design and easily accessed components, such as the core rotor device, offer a small footprint and easy access for servicing.

MELT PUMP, FILTRATION NEWS

At K 2016, PSI-Polymer Systems Inc., Conover, N.C., introduced a new servo drive for its EGP and CIP Series gear pumps. The drives allow a level of precision for starting, stopping, and ramping that is not possible with standard DC or AC motors. PSI accomplishes this by combining the linearity of the constant volumetric output/rpm of the gear pump with the precise positional control of a servo drive. The result is elimination of the independent gearbox, zero coasting of the motor, extremely fast reaction times, instant start/stop, fast ramping up/down, and a new feature—reversing. Reversing allows the servo drive to instantly back up the pump to eliminate any potential for overflow or drip, unlike a simple stop.

In filtration, PSI also announced that it had developed and field tested a truly leak- free screen-changer seal for high-tempera- ture, low-viscosity extrusion coating. This process has typically presented a difficult challenge for slide-plate screen-changer seals. Mechanical seals utilize clearances between the seal and body (typically 0.001 to 0.0015 in. radial) to accommodate removal and replacement. For typical process applications, polymer viscosities are too stiff to pass through these clear- ances, and the machines run trouble-free.

But extrusion coating often runs at or above 630 F, resulting in extremely low viscosities, which can pass through radial clearances as tight as 0.0005 in. Compounding this problem is the typical placement of the screen changer above the die. Any polymer leak from this position will compromise the web or drip onto the die.

Because of this, most extrusion coating operations use a cartridge-block filter that requires manual change-out, is difficult to access, and is labor intensive. PSI has successfully resolved slide-plate screen- changer leakage problems for extrusion coating through a proprietary upgrade of its patented lifetime, pressure-activated seal. The change introduces a conformable, heat-resistant (1200 F) annular seal component that stops polymers with extreme low viscosities from migrating around the OD of the seal.

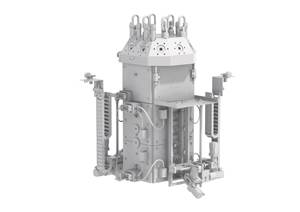

Meanwhile, Maag’s new x6-class pump is said to offer vastly improved volumetric effi- ciency, reducing residence time and making it possible to operate at reduced rpm, shear rates, and temperatures. This boosts production rate, polymer quality, and pump lifetime while significantly reducing energy consumption. Due to the enhanced pressure capabilities, finer filter meshes can be used farther down the line. And a higher volumetric efficiency and fewer pulsations are said to provide more constant quality and output of the final product.

A new-generation unit from Nordson reportedly provides up to 15% greater throughput without an increase in rpm. The BKG BlueFlow gear pumps reportedly offer more efficient melt delivery, better sealing performance and more sealing options, and improved control over melt parameters. Nordson has also enhanced the design of its patented “power back- flush” V-Type screen changer, reportedly creating a more compact and efficient system whose continuous operation eliminates downtime. Nordson’s BKG HiCon V-Type 3G screen changer uses a hydraulically powered backflush system to automatically remove contami- nants while maintaining extrusion throughput and keeping flow and pressure constant.

High-Technology Corp., Hackensack, N.J., used K 2016 to launch

its new Model BPC screen changer, designed for operation at pressures up to 5000 psi and differential pressures as high as 1500 psi. The new design utilizes proprietary flow channels and breaker-plate geometry to form a balanced polymer seal that promotes consistent screen displacement. The company says outstanding results have been achieved in a wide range of challenging applications, including flexible PVC precision tubing as well as coex cast film lines running highly filled polymers requiring ultra-fine filtration.

Related Content

OMV Technologies Gets New CEO

Kooper brings 33 years of experience in the industrial and consumer packaging industries to OMV--the closed-loop, turnkey, inline extrusion, thermoforming and tooling systems manufacturer.

Read MoreRoll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

Read MoreDie-Lip Adjustment System Relies on Motorized Actuators

Nordson will debut an automated lip adjustment system for its EDI extrusion and fluid-coating dies at the K 2022 trade fair.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More