Suppliers Running Precision Fluoropolymer Tubing at Medical Show

Catheter tubing with an x-ray stripe made with contributions from four equipment suppliers.

Apart from the triennial K Show in Dusseldorf, extrusion system suppliers don’t operate lines at trade fairs that much anymore. But at February’s MD&M West 2017 show in Anaheim, Calif., four suppliers teamed up to display a coextrusion line running a 1.4-mm-OD FEP fluoropolymer catheter tube throughout the exhibit.

The ¾-in. main extruder was from Davis-Standard, Pawcatuck, Conn. A second D-S ¾-in. extruder pumped equally spaced white FEP stripes filled with barium sulfate for x-ray opacity. The extruders are part of D-S’ signature MEDD (Medical Extruder Direct Drive) line, which uses direct drive for more efficient operation as well as greater materials flexibility. MEDD also has a replaceable feed-section liner, interchangeable barrel assembly, and Windows PLC control system.

Material streams were combined in a crosshead coex die from Guill Tool & Engineering, W. Warwick, R.I., so that four white stripes were embedded at 90° intervals around the circumference of the tube. Both the extruders and die package had streamlined designs to minimize residence time, owing to FEP’s tendency to burn.

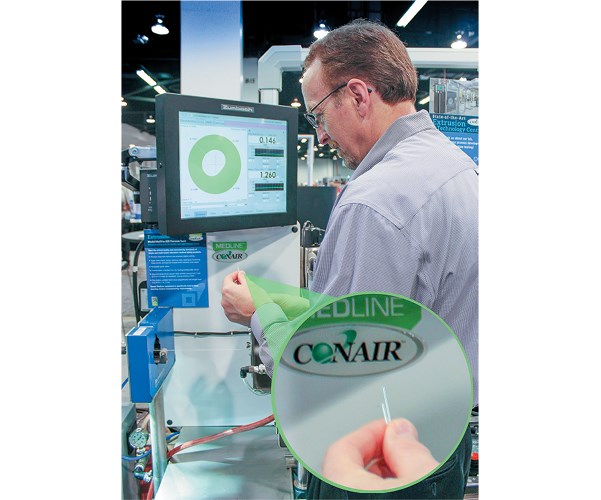

From the die, the tube entered a MedVac vacuum-sizing/cooling tank from Conair, Cranberry Township, Pa. An ultrasonic gauge inside the tank monitored the 0.4-mm wall thickness, while a 3-axis laser OD gauge from Zumbach Electronics, Mt. Kisco, N.Y. downstream of the tank provided closed-loop dimensional control and displayed the tube for concentricity adjustments. A vision system was also incorporated into the line to detect gels and surface imperfections and enable automatic separation of rejects inline.

The tubing then passed through a Conair MedLine puller/cutter, and cut lengths were carried away on a Conair medical belt conveyor. On the conveyor, cut pieces tagged as rejects by the OD/ID gauge readings and inline machine vision could be removed from the production stream with a puff of compressed air. The MedLine puller/cutter has a scrap/QC mode that accepts all three inputs (from the wall-thickness gauge, laser OD gauge, and cameras) and automatically sets a length offset so the cutter “knows” when the defective piece will reach it. Then the cutter can be programmed either to cut tubing differently from good product or not cut at all, or it can change the way a defective section is handled by the conveyor.

Related Content

-

How to Estimate and Control Head Pressure

You rightfully worry about melt temperature, but don’t overlook head pressure, because the two are closely linked and will influence line performance.

-

Understanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

-

The Importance of Viscosity in Melting

The calculations required to determine the right melt temperature for each polymer are complicated. Knowing the power-law coefficient and the consistency index of the polymer you run might prove useful.