Sustainable Sheet: Placon Closes the Loop on PET Recycling

Placon reprocesses up to 12,000 lb/day of PCR PET to produce its EcoStar line of sheet.

Placon has been innovating since it opened its doors in 1966. This family-owned sheet extruder and thermoformer, which employs more than 450 people in Fitchburg, Wis., DeForest, Wis. and Elhart, Ind., is a long-established market leader in designing and manufacturing packaging using a wide range of materials—including PET, PETG, R-PET, HIPS, HDPE, PP and even PUR—for food, retail, and medical applications.

So it should come as no surprise that when the company wanted to make a statement in PET recycling, it did so in a big way. In 2011, Placon started up EcoStar, which operates out of a 70,000 ft², $14 million closed-loop recycling plant (with 36,000 ft² devoted to bottle washing) in Fitchburg that reprocesses up to 120,000 lb/day of post-consumer recycled (PCR) PET bottles and thermoforms into flake and sheet, some of which is used in direct food-contact applications.

Utilizing post-consumer scrap is not a new concept for Placon, whose sales in 2012 were in excess of $100 million. “We’ve actually been using PCR content for years,” remarks Jeff Lucash, director of sales. “But at the same time, we saw the value and opportunity to do something more, to push a little beyond the current industry standard, to lead the market.”

Adds Dan Mohs, Placon’s CEO, “Our investment demonstrates our commitment to sustainable packaging and the reduction of solid waste. We believe that the best way to reduce energy consumption and conserve resources, from a cradle-to-grave perspective, is to recycle plastic packaging back into plastic packaging, thereby closing the loop.”

The EcoStar plant converts that concept to reality. While not the first operation to vertically integrate bottle recycling and sheet extrusion, EcoStar is certainly one of the first thermoformers in the food and consumer-goods packaging market to build its own in-house recycling facility to process post-consumer bottles and thermoforms. Billed as the largest operation of its kind in the Midwest, EcoStar has the capacity to handle 36 million lb/yr of recycled bottles and thermoforms. “Our vision is to completely close the loop—have our packages used and consumed, collected, and then reused again,” says Mohs.

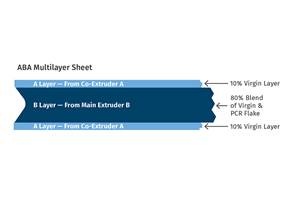

EcoStar’s main product lines include its PC50 sheet (a post-consumer PET sheet with up to 100% recycled content) and its RPET-F food-grade sheet incorporating at least 50% (and up to 100%) recycled content. “We plan on being the highest-quality player in post-consumer sheet, with products that cross into all of our established markets: food service, medical, and retail,” states Lucash. “With more and more focus on providing sustainable packaging solutions, thermoformers, driven by customer demand, are requiring responsible packaging products to meet their own sustainability initiatives. Regulations, such as the newly revised California Rigid Plastic Packaging Container (RPPC) law, are also spurring demand for recycled post-consumer packaging,” Lucash points out.

EcoStar has one customer in parent company Placon. The thermoformer utilizes EcoStar PC50 sheet in most of its current retail stock products as well as in a number of custom-designed retail packaging items, while EcoStar RPET-F sheet can be found in the company’s PET stock and custom food product lines. Some of Placon’s own thermoformed PET packages no doubt make their way back to EcoStar, making Placon both a customer of EcoStar extruded sheet and a supplier of material.

THE RECYCLING PROCESS

The EcoStar recycling facility operates on a 24/7 basis, states Jerry Figi, EcoStar’s assistant production manager. It can handle about 120,000 bales/day, with an average bale weighing about 1000 lb. Material is sourced from local Materials Recovery Facilities (MRFs), as well as from Placon itself.

The compressed bales of bottles and thermoforms are loaded onto a conveyor, which feeds the bales to a bale breaker, reducing the bale to individual bottles and thermoforms.

The breaker then meters the stream of separated scrap to the pre-wash station. The scrap goes through a tumbler, where steam and caustic solution remove labels and dirt from the outside of the bottles and thermoform scrap.

Bottles then are routed to an automatic bottle-sorting system utilizing infrared inspection to sort out non-PET material. An optical camera is deployed here to sort out the colored bottles. After that, operators remove final contaminants, and a large wet granulator grinds the bottles and thermoforms into flake.

The flake then passes through a high-speed tumbler, which separates out the water along with paper and other contaminants. Flakes are conveyed to a silo, and then to a reaction tank for hot washing. A carefully metered amount of flake is mixed with detergent and hot, caustic water to remove dirt and glue.

Flake is then tumble dried, and conveyed to a separation tank. In the tank, bottle caps and rings are separated from the PET flake. The PET flake sinks while the caps and rings float to the top, where they are skimmed off. Flakes are then rinsed one final time.

Next, flakes are dried mechanically, then with hot air, before going to a metal separator. At this point flakes can be diverted to decontamination equipment for direct food-contact applications. Flakes are then transferred to a mixing silo and on to an elutriator, which removes any remaining fines and dust. Flakes are stored in super sacks that can weigh up to 1700 lb.

Some of the scrap materials that are diverted from the PET recycling operation are sold to other reprocessors. Megan Moore, process engineer, leads the QC effort and is charged with final formulation of the material blend that is fed to EcoStar’s extrusion line. “Bale quality tends to vary a lot, so it’s important that we dip into smaller samples and test them to ensure quality and processability.”

Related Content

Sustainable Materials is Focus of Thermoforming Exhibits at K 2022

Thermoforming equipment makers including WM, Kiefel, and OMV will showcase processing of recyclable and biobased materials.

Read MoreThermoforming PCR: An Equipment Supplier’s Pointers

Thermoforming PCR is not radically different from forming virgin, but variation in recycled materials can require extra care to get a consistent end result. Start by examining every aspect of the process from the sheet (and extrusion process if run inline) to the final trim.

Read MoreThermoformer Maximizes Productivity with 3D Printing

Productive Plastics has created an extensive collection of 3D printed manufacturing aids that sharply reduce lead times.

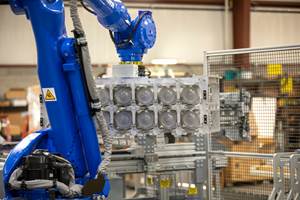

Read MoreAn Automation 'First' for Non-Servo-Eject Trim Presses

Compact, flexible and configurable robotic system is said to be the first to enable thermoformers to fully automate product handling after a non-servo trim press.

Read MoreRead Next

Sustainable Thermoforming: Efforts at Dordan

Family-owned former has been in the forefront of sustainable thermoforming and package design for years. Has it been worth the effort?

Read MoreSustainable Injection Molding: Amcor and the Big Picture

How the world’s biggest producer of PET packaging measures the environmental footprint of its operation.

Read MoreIt Ain't Easy Being Green

But efforts by packaging processors to become more sustainable will be worth it.

Read More