On-Site: The Buck Stops Here

Fully integrated manufacturing and an unwavering commitment to quality has helped position NELMAR as the ‘gold standard’ in tamper-evident security bags.

If you aren’t familiar with NELMAR Security Packaging Systems, odds are your money is. If you go to banks, eat at restaurants, roll dice, play blackjack at a friendly casino, or even had the unfortunate experience of being arrested, your cash—paper and coins—has quite possibly found its way into one of NELMAR’s tamper-evident security bags. Headquartered outside Montreal, Quebec, this vertically integrated, privately held firm combines advanced multi-layer film processing, proprietary bagmaking, and state-of-the-art printing under one roof to capture what it estimates is a 40% share of the security-bag market.

And if Neil Freder has his way, you ain’t seen nothing yet. The energetic, high-spirited CEO, president, and co-founder of NELMAR has an unwavering commitment to quality and innovation that’s reflected in constant evaluation of the firm’s technology. This year, NELMAR has a $15 million to $20 million capital-expenditure budget.

Freder is a self-proclaimed “business guy” with no college diploma and an innate understanding of manufacturing and technology. He got into plastics in 1984 when he and partner Mary Golfman formed Marnel Packaging, a supplier of shopping bags. A few years into that venture, Freder was approached by a friend with an idea for a fully recyclable plastic, tamper-evident, single-use security bag. At the time, the market was held by cloth and woven PP bags. In the armored-carrier industry, this technology wasn’t particularly efficient. Security personnel had to extend their time outside banks to wait for the empty bags to be returned to their customer, which resulted in delays and limited the number of stops an armored carrier could make in one day.

“Almost by accident, we figured out how to make these bags,” Freder recalls. In short order, he and Golfman shut down Marnel, sold off the bagmaking equipment, rejiggered the company name to NELMAR, and brought in new bagmaking and printing machinery to produce these new products. From the outset, NELMAR has added technology of its own to its bagmaking operations, which Freder calls the company’s “secret sauce,” giving NELMAR a competitive edge in the market.

Today, NELMAR employs 170 people and has capacity to run 600 million bags/yr. At that rate, you might expect to see dedicated lines running the same product day in and out. In fact, it’s quite the opposite. Freder considers NELMAR to be fast and nimble, capable of running orders from 20,000 to millions of bags.

Regardless of the size of the order, one value holds true: “We constantly try to innovate, to invest, to invent,” states Freder. “We are the largest tamper-evident bag maker in North America and perhaps the world, but it isn’t just about size. It’s about quality. Perfection is the desired outcome of every project we undertake. It is an attitude that has long been embedded in our culture. It exists simply because we believe that our customers are entitled to it. It’s our feeling that NELMAR is the gold standard of the tamper-evident bag business, the Ferrari of the industry.”

Adds Freder, “Every one of these bags is scanned during production. The possibility of missing side seals or unreadable barcodes has been completely eliminated through utilization of advanced technology. Our computerized collection and verification process has eradicated any instance of human error.”

NELMAR developed a technology called SureTraxx whereby every bag is scanned for barcode readability and is registered in a database. The serial numbers of the first and last bags within a given box are imprinted on the outside of the box in both human-readable and barcode form. Every bag number in the sequence is accounted for and guaranteed to be present in the box. The numbering-sequence barcodes on the side of each box are scanned at the departure point before being shipped to any store/branch within a chain. The receiving store/branch will then be responsible for every bag in the number sequence that was scanned at the departure point.

If a store deposit bag arrives at a bank with incomplete information in the depositor-information area, the bank can simply contact the departure location at which the boxes were originally scanned and then confirm which store/branch received the numbered bag in question, allowing the bank to post the deposit to the proper account.

NELMAR is a supplier to many Fortune 500 companies, and maintains that it produces one of the few tamper-evident bags on the market that cannot be opened and re-sealed without showing signs of tampering.

NELMAR’s extrusion and printing operations run 24:7; bagmaking recently moved to a 24:7 schedule too.

ADDING EXTRUSION TO THE MIX

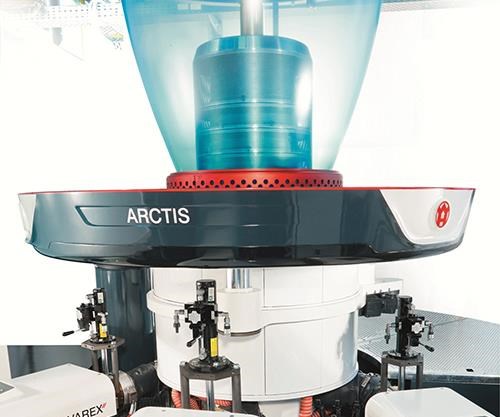

It wasn’t until nine years ago that NELMAR decided to add film extrusion to its technology mix. It hired a consultant and, as Freder recalls, “We went on a whirlwind tour of just about every supplier of blown-film extrusion equipment in Europe.” Ultimately, NELMAR chose a three-layer Varex blown film line from Windmoeller & Hoelscher Corp. (U.S. office Lincoln, R.I.) that had a working width of 71 in. (1800 mm) and was equipped with the Optifil P3 gauge-control system and a Filmatic S dual surface winder installed in a face-to-face configuration with reverse-wind capability.

“Of all the equipment options we looked at, this was the most expensive,” says Freder. “But at the same time, it was also the fastest, yielded the highest-quality film with the best tolerances, and gave us fastest return on investment.” With the purchase, Freder says NELMAR became the first supplier of tamper-evident security bags to integrate backward into film extrusion. “We are in the position to offer customers products made in an environment where we have total process control, from R&D to extrusion, printing, bagmaking, warehousing, and distribution,” notes Freder.

The film extrusion operation goes by the name of Plastixx Extrusion Technologies Inc. Some 15,000 ft² of NELMAR’s 200,000 ft² facility is devoted to film extrusion in a plant that has 5% positive pressure to eliminate dust and bugs and provide a more stable bubble.

Currently, the company has three W&H lines, all of them three-layer, including the second-generation Varex II introduced at K 2013. A fourth five-layer Varex line is planned for delivery in 2017. Plastixx runs approximately 20 million lb of the gamut of PEs, as well as PP and a variety of additives. Plastixx film feeds both NELMAR’s security-bag operation and another related company, Plastixx FFS Technologies. This sister company manufactures tubular form-fill-seal bags for packaging cementitious materials, fine powder, resin, granular products, pet food, and more.

NELMAR has found that adding film extrusion to its technology portfolio has given it more control of the entire process and increased overall bag quality. States Freder, “Coin bags were generally 5-6 mils thick, but after they were starting to fail, the Federal Reserve thought they needed to be thicker. Yet ours maintain their integrity at 4-4.5-mil thick.” The company tailors material recipes to generate the highest-quality film at the thinnest gauge while maintain key properties such as dart impact and elongation at break. “You’re putting a ‘brick’ of money in thousand-dollar notes in a bag, and this brick has very sharp corners that could easily tear the bag.”

NELMAR’s most recent investment was in a W&H Vistaflex CM 10-color printing press. The new machine will increase print speed from 1650 to 2000 ft/min while decreasing changeover times. Furthermore, its ability to print larger rolls of film will result in fewer roll changes and less overall waste.

NICHE MARKETS

Most wouldn’t consider an enterprise with extrusion capacity of 28+ million lb/yr and bagmaking capacity of 600 million units to be a niche player, but NELMAR sticks to its specialized market with a wide-range of tamper-evident bags customized to the application. The company has a graphic-design team that works with customers to create a print layout of their bag design in any size and color combination. This layout can incorporate a customer’s branding elements, specific usage instructions, and write-on information particular to their system; it can even include detailed four- to 10-color process pictures. This flexibility notwithstanding, NELMAR won’t bid on a job without full disclosure on the part of the customer. “If we get calls for an RFQ we always request a sample,” Freder says. “If we don’t get one, we don’t bid on the job.”

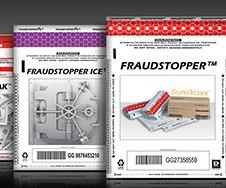

The company’s core product line (all of which are based on three-layer film structures) includes the Fraudstopper, which offers what NELMAR says is the most sophisticated “in-line” or “flat” proprietary security closure available on the market. Opening and resealing the bag without showing signs of tampering is impossible. The user-friendly closure includes a self-sealing mechanism that offers high-tech security features for retail deposit bags, bank deposit bags, vault bags, coin bags, evidence bags, biohazard bags, patient property bags, and duty-free bags. The bag is categorized as a Level 4 (the highest security ranking) tamper-evident bag, meaning it incorporates both heat- and cold-tamper indicating technology.

Two other products, Secur-Pak and Blue Adhesive, utilize “fold-over” tamper-evident closure systems. Blue Adhesive products close over a security pattern that becomes distorted when the bag is opened and resealed. And NELMAR’s Fraudstopper Assure is the only patented self-sealing tamper-evident package that incorporates a unique micro-perforated non-woven and highly tear-resistant material specifically designed for use with dye-pack or ink bomb-enabled security transport systems.

NELMAR also maintains a stock-bag program of more commonly ordered sizes in single-pocket, single-pocket with external pouch, and vertical or horizontal two-pocket deposit formats. The company recycles 100% of its post-production scrap.

Related Content

Variable-Diameter Air Ring Cools Film Above Frost Line

Tower-mounted adjustable ring adds cooling so that blown film can run at optimum line speeds with structures having soft inner skin layers that tend to block.

Read MoreFilm Processor Automates Complex Resin Management, Blending & Distribution System

Polipak of Poland moves to BlendSave system to support sustainability and Industry 4.0 objectives.

Read MoreYoung Stretch-Film Processor Bets on Nanolayers

Going up against companies with as much as double its capacity, young stretch-film processor Zummit believes that new technology — notably 59-nanolayer films — will give it a competitive edge.

Read MoreAir Ring Add-On Brings Output to New Level

The Short Stack from Addex sits between the air ring and die and provides high-velocity air flow to boost output and lock in the bubble.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More