The Importance of Specific Heat in Screw and Extruder Design

If you ever have to size an extruder drive, knowing the specific heat of the polymer can help you to determine the capability of your equipment.

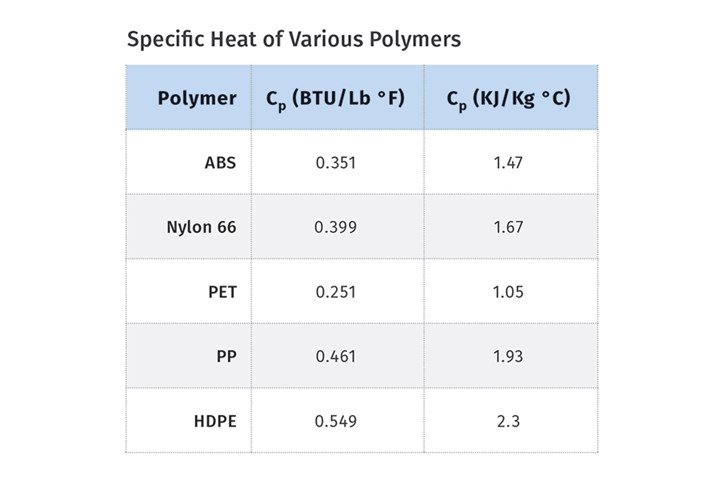

A lot of polymer physical properties are involved in screw design. One that’s required for all screws is the specific heat of the polymer. Specific heat is the amount of energy required to change the temperature of a unit of mass by one degree. BTU/lb/ºF or J/g/ºC are the most commonly units used in screw design although there are many more units used for scientific purposes.

The specific heat is equal to the amount of heat it takes to change the same mass of water by 1º F or 1º C. For example, if a specific heat of a polymer is 0.3, it means that it takes 30% as much heat to raise the temperature by one degree as an equal mass of water. Its usual designation is Cp in most formulas.

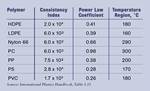

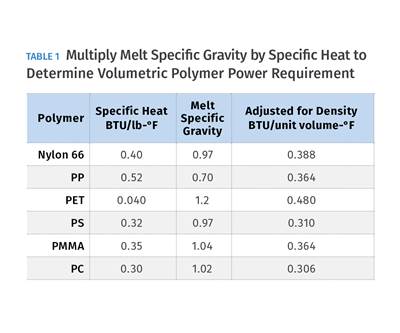

As you can see from the accompanying table, it takes more than twice as much energy to raise a pound of HDPE by one degree than a pound of PET. This varying power requirement is why modern screw designs are most often specific to the polymer being processed rather than being the old “general-purpose” screws.

When designing a new screw, one of the first considerations is to determine whether enough power is available for the chosen polymer and desired output rate. A simple formula can be used, because once the screw starts rotating, almost all the power for melting or raising the polymer temperature comes from the drive, due to the poor thermal conductivity of polymers.

When designing a new screw one of the first considerations is to determine whether enough power is available for the chosen polymer and desired output rate.

For example, if we had a 6-in. extruder with a top speed of 150 rpm and a screw design to produce 4300 lb/hr of PET at that speed, how much horsepower is required?

There is a simple formula to determine the power required:

0.00053 × Delta T0 × Cp × lb/hr ÷ Drive Loss = hp required

Keep in mind that some polymers are preheated before processing to remove moisture, and that subtracts from the required Delta T0 (difference in temperature entering extruder to desired melt temperature). In this case PET is often processed at 530 F but is predried to 300 F, so the energy requirement only need to be enough to raise the temperature by 230º F. The 0.00053 is simply a conversion factor that converts all the units to horsepower and has no other meaning. A drive-loss factor of 0.9 or 10% is more than adequate for most AC and DC drives.

The hp calculation for PET becomes:

(0.00053 × 230 F × 0.251 × 4300) ÷ 0.9 =146 hp at 150 rpm

Since no one likes to run their extruder motor at full amps, I typically divide by 0.75 so the planned drive amps are about 75% of full load under normal operating conditions (146 hp ÷ 0.75=195 hp at 150 rpm). I would typically round this up to the next standard motor size, which is 200 hp. The 75% factor accounts for any variations in preheat, polymer properties and other operating conditions without seeing a motor overload. (Note: Torque is force while horsepower is torque × rpm.)

Purchasing an extrusion line sized for a low-power-requirement polymer such as PET will forever limit the utility of the extrusion equipment

If a similar screw design was to process HDPE in the same extruder:

(0.00053 × 300 F × 0.549 × 4300) ÷ 0.9 = 417 hp. Again, putting in the safety factor and adjusting to the next motor size:

417 ÷ 0.75 = 556 hp, which gives a 600-hp drive motor.

As you can see, the differences in Cp, melt temperature and preheat can make a huge difference in the required drive power. Comparing PET and HDPE, the HDPE requires nearly three times as much horsepower as PET to bring it to typical processing temperature due to the combination of specific heat and preheating of the PET.

It’s important to keep in mind that commercial requirements may change over time, and purchasing an extrusion line sized for a low-power-requirement polymer such as PET will forever limit the utility of the extrusion equipment. But even if you never have to size an extruder drive ,this can clarify the difference in power requirements between different polymers and allow you to determine the capability of your equipment with different resins and melt temperatures.

ABOUT THE AUTHOR: Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 50 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724) 651-9196.

Related Content

How to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

Read MoreA Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

Read MorePBT and PET Polyester: The Difference Crystallinity Makes

To properly understand the differences in performance between PET and PBT we need to compare apples to apples—the semi-crystalline forms of each polymer.

Read MoreAre Your Sprue or Parts Sticking? Here Are Some Solutions

When a sprue or part sticks, the result of trying to unstick it is often more scratches or undercuts, making the problem worse and the fix more costly. Here’s how to set up a proper procedure for this sticky wicket.

Read MoreRead Next

Extrusion: The Role of Polymer Density in Screw Design

Density affects the mass flow rate, and energy transfer is based on mass, not volume. As a result, polymer density enters into practically every calculation in a screw design.

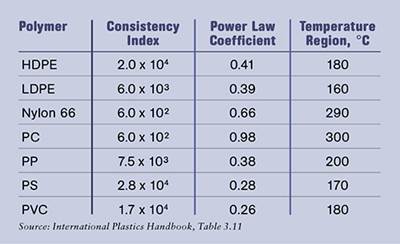

Read MoreThe Power-Law Coefficient

By referring to the power-law coefficient, the effect of barrel override in the metering section of many screws can be explained and anticipated.

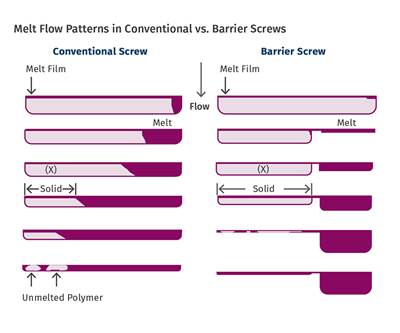

Read MoreExtrusion: Important Polymer Melting Equations for Extrusion Processors

The more you know about what happens in a screw, the more you’ll be able to work with your supplier to optimize design.

Read More.jpg;width=70;height=70;mode=crop)