The Tools of Tool Maintenance

The root cause of many mold and part issues are ultimately determined by the ability to measure something within one or two tenths of a mil. Readings with precision measuring tools can determine whether a tooling component is to be reused, reworked, or scrapped out.

Measurement and inspection of components of close-tolerance tooling is a necessary maintenance skill for repair technicians to determine how the tolerances compare with print specifications during a comparative analysis or checking tooling stack-ups. The root cause of many mold and part issues are ultimately determined by the ability to measure something within one or two tenths of a mil. Readings with precision measuring tools can determine whether a tooling component is to be reused, reworked, or scrapped out.

Several considerations must be met when using precision measuring tools to check dimensions accurately to within 0.0001 in. The most commonly used repair tools are micrometers, test indicators, and calipers. Some toolmakers have a collection of these tools of various quality, styles, dimensional capabilities, and costs. The quality of the instruments you choose should be based on usage, cost, and the level of professionalism you want to achieve and project. It used to be that a journeyman repair technician’s precision tool selection was as much a part of his qualifications as his ability to use them. Nowadays, the new breed of technician is more about what the company can provide, for the onus of ownership has shifted, and the reverence for using one’s own precision tools is diminishing.

So regardless of whether you purchase your own measuring tools or your company has its own community chest of precision tools (not always a good thing), there is some basic information to consider whenever precision tools are purchased, used, and cared for.

•Conditions of use: The first question to ask yourself is how close do your type of molds and products require you to work? Are you maintaining liquid silicone rubber (LSR) molds or grinding vents for nylon (extremely small flash points)? Or are you molding dogfood bowls where the flash is being trimmed by hand? If you absolutely don’t need to measure to within 0.0001 in.—and most often you don’t—then spend the extra money on tool quality instead. A readout of 0.0005 in. is usually close enough, and in many cases 0.001 in. will suffice. Also consider how often you will use the tool. Even a $45 dial indicator used once a month will last a while, and when it breaks or needs repair you can just toss it.

This brings us to the issue of tool reparability and availability of spare parts. It’s practically impossible to get spare parts for cheap measuring tools or to have them refurbished. It’s especially hard to get parts for electronic tools, as they change in design about every three years.

Many mold-repair technicians working on close-tolerance tooling will be pulling out their precision tools every day, so they should buy the highest quality tools they can afford. Take care of them and they should last a lifetime.

•Reliability/accuracy: Most important is the accuracy of the measuring device. Cheap tools will force you to fiddle with them to get an accurate and repeatable reading—planting doubt in your head that will only cause you grief and stress with their inconsistent and unreliable answers.

Today, there are many more types and styles of measuring tools to choose from, and for much less pain in the pocketbook. Precision tools are like everything else produced today: Their manufacture has spread to foreign shores, resulting in cheap copies. Low-cost devices use plastic gears, springs, bushings, and epoxy in place of cast metal parts, nuts, bolts, and jeweled movements. For micrometers and calipers, journeymen toolmakers and repair technicians will use and recommend those made by the old stalwarts such as Mitutoyo, Starrett, Brown & Sharpe, Tesa, and Etalon. Farther downstream you have SPI and Central Tool, and then a host of cheap tools made in China and Poland. You can identify these quickly, as there is typically no name on the tool and they are unbelievably cheap, like $12 for a 0 to 1-in. micrometer.

For dial test indicators, the best are typically Swiss-made, such as Bestest, Compac, Interapid, and Tesatast. All of these are made by the same manufacturer in Switzerland, and a couple in U.S. plants.

•Type of action/readout: You basically have three choices with precision tools: mechanical (spindle), dial (needle), or digital readouts. The best choice depends on which tool (micrometers, calipers, or dial test indicators) you purchase. As a general consideration, digital readouts have become extremely popular for calipers and micrometers, and some are even solar powered for the “green” fans. They are easy to read and switch from U.S. to metric, and to establish a “zero” dimension in which to perform a comparative analysis. The drawbacks are getting them repaired, as they are easily broken and some cleaning solvents will eat the plastic faces.

Mechanical or dial readouts are still popular with us boomers since most of us probably bought quality tools and kept them in good shape. They must be cleaned often, and depending upon how hard you are on them, nee to be adjusted or calibrated more frequently than digital tools.

Decent electronic calipers are usually of better construction than dial calipers, as there are fewer moving parts to wear out. They also feel smoother in use because they don’t have gears or a rack, and they are great for feeding multiple readings to a software program

•Storage and care: Moisture, rust, dirt, grime, and metal chips are all enemies of precision tools as much as drops and misuse (like cranking down to fudge a reading). Keep tools in their cases or covers and occasionally wipe them down with a light coating of 3-in-1 oil if rust is an issue. But nothing at all is usually the best.

Digital micrometers should not be disassembled or tampered with or stored with the faces of the spindle touching. If you get a chip in the spindle of a micrometer, be very careful not to force the spindle to turn or you can ruin the threads. Send it to a pro to be serviced.

Speaking of pros, there are dozens of other factors that that won’t fit into this article that involve specific brands and types of precision measuring tool one must consider before dropping serious dollars. A great place for information concerning all things precision is the website, longislandindicator.com. of Long Island Indicator Service in New York. They will let you know exactly what they think of certain brands and types of precision tools. They are old-school toolmakers (40 in the shop) who repair the precision tools that we use every day. Listen to their advice, and save some money as well as frustration in order to achieve reliable, repeatable, accurate measurements.

Related Content

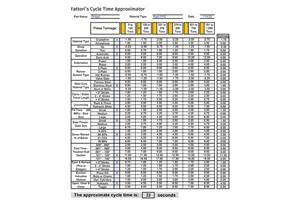

How Do You Estimate Cycle Time?

Molders price jobs based on estimated press time, and that is where you can either be very profitable or lose your shirt. But there’s a new, free resource to help you out.

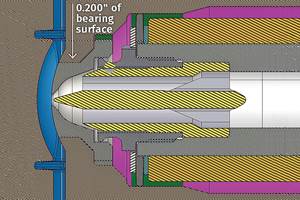

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreHot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More