Torque & Speed How Much Is Enough?

You may be thinking of buying one of the new ‘high-torque/high-speed’ twin-screw compounders in order to raise your output without going to a larger machine. But how much torque or speed do you really need? Underusing a high-powered extruder wastes investment dollars. So look carefully at what is required for the materials you run.

It has been seven years since Werner & Pfleiderer, now Coperion W&P, launched the first high-speed, high-torque twin-screw compounder at the K ’95 show in Germany. Its new MegaCompounder offered at least one-third more output than the same size conventional corotating twin-screw. In the years since then, virtually every maker of corotating twin-screw extruders has followed suit with its own models of higher-torque, higher-speed machines.

Most customers, it seems, are happy to get higher output from a smaller machine. A smaller machine is also easier to clean out. Knowledgeable sources report that filled polyolefins, most TP polyesters, ABS, and glass-filled nylon 6 generally do well under high-speed, high-torque conditions.

But high speed doesn’t benefit shear-sensitive resins like LCPs and high-performance nylons. The same is true of heat-sensitive additives and very low-viscosity materials like reactive compounds or low-bulk-density materials like wood-filled or highly talc-filled mixtures. Throttling back a high-speed machine to run such materials is an inefficient use of the extra investment.

“Torque and speed are separate issues. Some material formulations need one but not the other; some need both,” explains Charlie Martin, general manager of Leistritz Extruder Corp. “There are three limits to an extruder: torque, free volume, and quality—which means either dispersion quality or processing temperature. Normally you reach the quality limit for a compound before you reach the other limits,” he says. (Free volume is the working volume inside the screws, calculated as the free cross-sectional area multiplied by the length of the screws.)

“The whole high-torque thing is something of a misnomer,” says Dan Smith, sales and marketing manager of Entek Extruders. “Customers think they want more torque, the way people want a more powerful car. The supposedly ‘high-torque’ machines are really high-speed machines because allowable torque for a 1200-rpm machine may be the same as for a 600-rpm machine. The key is to design machine speed and torque requirements for the application. Since higher rpm means higher shear rates and melt temperature, lower rpm and higher torque may be better in many cases.”

Talk about torque

If torque specs influence your machine purchases, then you better know what vendors are talking about. Torque is basically twisting force, measured in ft-lb or Newton-meters (Nm). Engineers use several common formulas to describe torque. Torque = hp times a constant (5250 for ft-lb or 9550 for Nm), divided by rpm. Or conversely, hp = torque times rpm divided by 5250 or 9550.

There is also a formula for a theoretical number known as torque factor, specific torque, or torque density. Torque factor = torque divided by the cube of the center distance between the screws. The torque factor for a corotating gearbox can be quoted for both shafts or just one. The value for one shaft is half that for two.

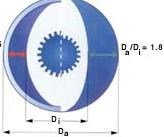

Compounding machines also have an “intermeshing ratio,” which is the outside diameter of the screw divided by the root diameter (OD/ID). There is also a “power ratio,” which is the intermeshing ratio divided by the torque.

Some machine builders present their machine power in terms of “enthalpy” or “specific energy,” a measure of how much energy is required to bring a plastic to melt temperature (measured in kwh/kg or hp-hr/lb). “If you have a lot of filler, you aren’t melting as much plastic and typically don’t need as much enthalpy,” explains Berstorff sales engineer Paul Rogers.

Machine builders are sometimes fuzzy about quoting their machines’ torque capacity—perhaps because of a German patent that W&P obtained in 1997, which covers extruder operation at a torque level greater than 11 Nm, intermeshing ratio of 1.5 to 1.65, and speed greater than 1000 rpm. The patent was challenged by a group of W&P’s competitors, but the issue still hasn’t been resolved.

Berstorff, for one, has chosen to stay clear of W&P’s patent, by designing its corotating twin-screws to run at higher shear and with more power than the range the patent covers. Berstorff uses a lower intermeshing ratio of 1.46, whereas W&P uses an intermeshing ratio of 1.55. The higher ratio entails more free volume, lower shear rate, and a smaller shaft diameter that withstands less torque. Berstorff’s intermeshing ratio of 1.46 gives 40% more power and higher shear.

“We feel 1.46 is the best intermeshing ratio for a wide variety of materials. It has less free volume but higher shear rate and higher torque because of the larger-diameter shafts, says Berstorff’s Rogers. “The truth is that both 1.46 and 1.55 will work on most applications, but one has an edge over the other in some materials.” In a similar vein, Farrel uses a ratio of 1.48 for its twin-screw compounder. Materials like nylon reportedly do well on lower ratios, while fractional-melt polyolefins and formulations that don’t use wax lubricants benefit from higher ratios.

High-speed, high-torque operation isn’t compatible with all fillers and additives. “We are very interested in the types of fillers customers are using and any temperature or shear restraints in the additives,” says Edward Wykoff, director of compounding at NFM/Welding Engineers. NFM normally builds only high-torque extruders but will supply extruders with lower-hp motors and lower-speed gear sets if needed.

W&P also switched all its production to its high-torque, high-speed MegaCompounders until it found that not every formulation fared well under high shear—particularly materials with low bulk density. Such materials have become more common, notes Paul Andersen, director of process technology for Coperion W&P. Wood flour is not the only example, he says: “Typical talc particle size used to be 10 microns. New sub-micron-size talc fillers are lower in bulk density.” At particle sizes of one micron or smaller, compounding with talc is limited by the screws’ free volume, not torque, he says.

Turn up the volume

In 2001, Coperion W&P introduced a MegaVolume version of its ZSK compounder to address needs for low shear and high throughput of low-bulk-density compounds. W&P made screw channels deeper with an intermeshing ratio of 1.8, allowing up to 50% more free volume.

Likewise, Berstorff introduced its “R” models, which have deeper screw channels to increase free volume and which use 20% less torque. Again, Berstorff stayed outside of W&P’s patent by going to an intermeshing ratio of 1.75.

Entek also offers an E-Mix line of extruders with more free volume and less torque than its E-Max line of high-speed, high-torque corotating twins.Higher free volumes and higher intermeshing ratios lower the shear stress on a compound when run at moderate screw speeds. However, machines with higher free volume and lower torque capacity can actually run at even higher screw speeds than so-called “high-speed, high-torque” models. W&P’s MegaVolume series goes up to 1800 rpm for diameters of 34 to 76 mm, and achieves up to 1500 rpm for diameters from 98 to 125 mm. W&P’s MegaCompounder runs at up to 1200 rpm for sizes from 25 to 70 mm. The upper speed limit drops for larger sizes—e.g., to 1000 rpm at 133 mm.

Shafts take an extra twist

Screw shaft L/D is the limiting factor for torque. A larger shaft can withstand more torque without risking breakage, but at the expense of less free volume and throughput capacity. Yet it appears that few processors think about shaft dimensions when they buy a twin-screw extruder. Machine builders often keep shaft dimensions and materials and methods of shaft construction confidential.

Shaft diameter has an economic impact when it affects a processor’s inventory of spare screw elements. One of W&P’s best-selling high-torque models is its 92-mm MegaCompounder, partly because in that one size the high-torque shaft has the same diameter as that of the previous, lower-torque SuperCompounder. So a processor that owns a 92-mm SuperCompounder can buy a 92-mm MegaCompounder and stock only one size of screw elements. MegaCompounder models either larger or smaller than 92 mm have greater shaft diameters for the same screw diameter than do previous machine models.

W&P’s high-torque machine shafts have spline profiles different from those of conventional SuperCompounders. The 24 splines on W&P’s high-torque shaft are flat on top to disperse torque more evenly inside the screw elements, whereas the splines on W&P’s previous lower-torque compounders are rounded.

Newer manufacturing methods for high-torque splines improve their strength. Cold rolling or hammer milling are used to finish the splines by compressing the steel, instead of merely cutting them to size. That results in a denser, harder metal surface. Machine makers also use higher-strength alloys and tool steels.

Leistritz takes several other approaches to strengthening shafts for higher torque, which allow it to keep the same shaft diameter in high-torque models as in conventional machines. For high-torque machines, Leistritz has delivered screws that are milled in one piece.

Owners of high-torque machines are sometimes hesitant to use all that available torque capacity for fear of breaking a screw shaft. An engineer at Century Extruders notes that “a good customer of ours runs at 80% of maximum torque and 80% of maximum speed, which is safe.” W&P’s Andersen says most customers run at 75% to 95% of maximum torque rating.

NFM’s Wykoff, however, thinks compounders frequently use too little torque. “They make the mistake of not keeping torque levels consistently high, believing they’re extending the life of the machine,” Wykoff says. “They don’t want to run it full out for fear of twisting or breaking a shaft, so they reduce output. We show them that by feeding more material and using higher torque, they get better dispersion and higher output.”

Some sources also argue that under-utilizing a powerful gearbox causes more wear on the gears. On the other hand, Peter Heidemeyer, W&P’s director of product development in Germany, says a turndown ratio (range of operating speeds) of 2:1 or even more usually creates no problem.

One way in which processors can protect their high-torque screws from damage is to take care in cleaning them. Processors often use ovens to burn plastic residues off screws. But since high-torque shafts are heat tempered, they shouldn’t be exposed to temperatures above 1050 F or they will lose their tempering and be weakened, says a Century engineer. For safety, he recommends that high-torque screws should not be cleaned in ovens hotter than 900 F.

Faster is not always better

Higher speed raises throughput and improves mixing, but it also raises melt temperatures, so thermally sensitive resins and additives don’t do well at high speed. “Even short exposure to high temperatures can cause degradation of a foaming agent or a heat-sensitive flame retardant,” says Peter Wickenheisser, director of process applications for Farrel’s FTX high-speed, high-torque, twin-screw compounder. He says the solution is to feed more material at the same rpm to bring melt temperatures down. Higher percentage of fill of screw flights improves both temperature control and mixing quality in a screw of the same free volume.

Screw configurations for high-torque, high-speed machines are often distinctive. “The clue is a much larger first kneading zone, which could have twice as many elements because material is passing through so fast that it needs more kneading to get uniform mixing. At the same time, screw conveying sections are typically shorter,” says NFM’s Wykoff. High-speed, high-torque machines are often—but not always—one or two barrel sections longer than a conventional twin-screw.

The highest screw speeds apply only to smaller screw diameters. W&P’s ZSK MegaCompounders go up to 1200 rpm but only in sizes up to 70-mm diam. At 133-mm, maximum speed is 1000 rpm. But for machines over 177-mm diam., the rpm limit drops rapidly. That’s because larger screws generate high “tip speed,” the speed at the tips of the screw flights. For a given rpm, tip speed increases with screw diameter—and so does the shear imparted to the plastic. To avoid excessively high tip speeds, larger machines are geared for lower maximum rpm. W&P’s 177-mm model is geared to go only to 550 rpm, the 380-mm model only up to 260 rpm.

High-speed, high-torque twin-screws reportedly have problems compounding some color masterbatches. Color masterbatches are typically 70% mineral pigment and 30% plastic. The plastic is usually in fine-ground powder form, so it melts more rapidly for maximum mixing with pigment powders. “These mineral-rich formulations are difficult to run at very high speeds,” says Robert Urtel, president of Century Extruders. W&P, however, says black, white, and color masterbatches can be run at 1200 rpm, though organic pigments are more heat and shear sensitive.

Most high-torque/high-speed machines are vented but still aren’t good at processes that require devolatilization. Depending on the screw configuration, running at high speeds doesn’t allow the residence time needed to remove volatiles. Vents are a particular problem in high-speed processing with materials that don’t adhere well to barrel walls, such as very high-molecular-weight polyethylene or very highly filled materials. “Plastic can actually be flung out of the vents,” says Farrel’s Wickenheisser.

Material feeders for high-speed machines also must be more accurate than with conventional lines (see PT, July ’02, p. 50). “If you have fluctuations in feeders, a high-speed machine is much less forgiving,” says W&P’s Andersen. “Fluctuations come from the hopper-refill cycle, so one solution is to install a bigger hopper to reduce the frequency of refills.”

The ultimate danger at high speeds is that a sudden process upset is potentially more damaging. Machines’ standard safety features include provisions for mechanical disengagement of the clutch and electrical cutoffs in case of a torque overload. These safety features are supposed to act instantaneously, but sources suggest they may be less effective at very high rpm. Century’s Urtel cites one example: “If a compounder is using continuous glass roving and the machine overloads, the plastic feed may stop, but the roving keeps wrapping and pulling, so it can break screw shafts. Processors have to realize that they’re operating in a much more unforgiving environment with little room for error.”

Related Content

Engineering Resins Compounder Expands to Take on More Scrap

Polymer Resources responds to sustainability push by upgrading plant with grinding and shredding equipment to take on both postindustrial and postconsumer reclaim.

Read More10 Ways to Improve Twin-Screw Compounding Performance

There are many techniques known to operators and plant engineers for increasing the performance of a twin-screw compounding extruder.

Read MoreImproving Twin-Screw Compounding of Reinforced Polyolefins

Compounders face a number of processing challenges when incorporating a high loading of low-bulk-density mineral filler into polyolefins. Here are some possible solutions.

Read MoreMore Than a Compounder: They Have the Science to Create New Custom Materials

Insight Polymers & Compounders leverages its expertise in polymer chemistry to develop next-generation materials.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More