Autodesk Inc., San Rafael, Calif., has just made available a new version of its Moldflow Insight software that takes time-consuming meshing and analysis functions off your desktop and performs them at a remote data center accessed via the Internet. What was formerly an invitation-only beta test project involving a few customers is now commercially available to all at a price that makes high-end simulation available to more customers than ever before.

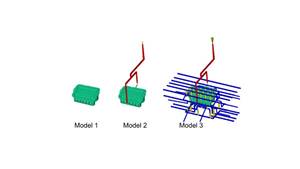

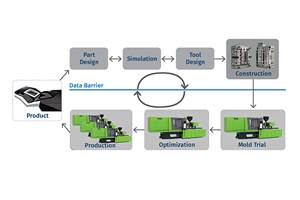

This “cloud computing” capability requires a license for a new software product called Autodesk Moldflow Insight WS (Web Services). It is based on the highest level of Moldflow injection molding simulation software—Autodesk Moldflow Insight Advanced. The capabilities of this $90,000 product are now available for as little as $10,000, which opens up high-end analysis to smaller or occasional users who previously could only afford a relatively simplified simulation program such as Autodesk Moldflow Advisers. Autodesk Moldflow Insight WS looks and works no different from the standard software, except that it is configured to send meshing and analysis functions only for remote processing ‘in the cloud.” It does not perform those functions locally. After preparing a model and selecting an appropriate mesh type, the user clicks “Mesh” and the job is sent out for processing. When meshing is completed, it is automatically downloaded to the user (or the user is alerted that the download is ready). After the usual mesh checking and cleanup tasks, the user sets up the analysis in the usual manner—selecting analysis sequence, process settings, injection location, and cooling channels. Clicking “Start Analysis” sends the model out again for processing, and finished results are downloaded once again.

Autodesk Moldflow Insight WS comes in three versions:

Standard provides 200 hr/yr of cloud computing, enough for about 150 small simulations. Cost: $10,000.

Premium provides 800 hr/yr of cloud computing, enough for around 300 medium simulations. Cost: $20,000.

Ultimate provides 2500 hr/yr of cloud computing, enough for roughly 500 large simulations. Cost: $35,000.

Apart from the reduced software cost, there are several other benefits of cloud computing: First, it gives every user unlimited hardware capability for intensive data processing—whether in the office or at home or on the road with just a laptop. It means users can now afford to perform multiple “what-if” iterations of a mold/part design or processing setup. Alternatively, they can optimize design and processing through multiple Design of Experiments interations. What’s more, users can now perform analysis of very large models with even tens of millions of elements, which were just not possible before, or required the user to simplify the model, sacrificing accuracy.

“Our release testing of cloud computing involved millions of elements and around 40 simultaneous analyses,” says Bob Williams, product marketing manager for Autodesk Simulation. “It was as much as our quality team had available to throw at it. We have customers telling us that 5 million elements give them a hard time with their current hardware capabilities. The current record we’ve been able to solve in the cloud is 27 million elements. We look forward to announcing new records as customers get the product and push the limits.”

Williams notes that, when all is said and done, a small simulation may not be done any faster in the cloud than on your desktop. That’s because uploading and downloading models and simulation results takes time. However, he believes that once you get over 1 million elements or stack up multiple simulations, you will see a clear benefit to cloud computing. “And even if you don’t save time in total on small models,” he points out, “you benefit because your computer is freed up immediately for other work.”

Meanwhile, Autodesk Moldflow has another new online offering, called the SIM Squad. This consists of some 60 experts available for consultation in all forms of simulation within Autodesk’s product line—plastics, mechanical finite-element analysis, and computational fluid dynamics. They are identified by name and specialty—not an anonymous Support department. Also on the site (reachable from autodesk.com/moldflow) are many videos, white papers, and discussion groups.

.png;maxWidth=300;quality=90)