What to See at NPE 2006: Extrusion

The new factor in extrusion machinery at this NPE is the influx of Asian suppliers.

The new factor in extrusion machinery at this NPE is the influx of Asian suppliers. We count 30 Chinese OEMs this time vs. five at NPE ’03 and 17 Taiwanese vs. six in ’03. Chinese exhibitors now are likely to have a North American or European engineering or sales alliance.

Some Chinese machine builders have adopted westernized manufacturing techniques. Jwell (Shanghai) Machinery, for example, is ISO 9001 certified. And Jin Ming Plastics Machinery has several years’ experience building oscillating hauloffs for a European maker of blown film extruders and now offers seven- and nine-layer blown film lines itself, though it has a three-layer line for its NPE debut. Jin Ming (North American offices at J.M. Machinery in Canada) incorporates European components such as a Kundig thickness gauge on a manually adjusted, Chinese-built die; and Schneider inverter drives from Germany on Chinese-built AC motors.

News in testing and inspection

Lots of new capabilities are shown for on-line quality checks. Gneuss developed a small on-line capillary Viscosimeter to determine polyolefin and PET I.V. A PLC generates shear and viscosity data, and the sampled melt goes back into the extruder.

Two NPE exhibitors brought new visual inspection systems based on LED light instead of lasers. Wintriss Engineering is introducing Refraction Ranger sheet inspection to detect super-fine MD scratches in films for window glass. Pixargus is introducing X-LightEdge surface and dimension inspection for profiles.

Isis Optronics’ new non-contact gauge uses IR reflection to measure overall film and individual layer thickness. Davinor is displaying a white-light interferometer gauge for layer thickness.

Less glamorous but very practical is the Melt Monitor from Dynisco, said to be the only combination extrusion pressure/temperature gauge on the market.

Going gearless

Machinery news includes wider application of gearless, synchronous, permanent-magnet torque motors, especially in blown film. NPE is a prime opportunity to explore motors, gears, and drives for extrusion because these component suppliers haven’t been allowed to exhibit at the K Show in Dusseldorf—the only plastics show bigger than NPE.

At NPE, however, Zambello of Italy (represented by STC Equipment) will display a new TST high-speed gearbox, said to have the world’s highest torque. German motor builder Baumuller is exhibiting its newest and largest gearless torque motor.

Gearless torque motors are actually running equipment at this show. Macchi will operate a coex blown film line with all-gearless motors from Siemens on three extruders, the oscillating hauloff, and five winder rolls.

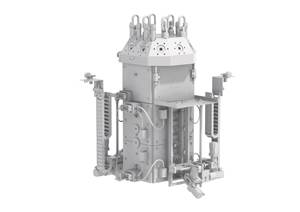

Davis-Standard is showing the first North American-built extruder with a gearless permanent-magnet torque motor (from Siemens) on its new EMDD (Electric Motor Direct Drive) extruder.

TechFlow Design & Manufacturing will show a video of its coex blown film line with gearless torque motors from Siemens, built in Italy this year at partner Giovanni Zocchi.

Reifenhauser, which showed the first gearless motor on an extruder at last NPE, has added three new extruder sizes (60, 80 and 90 mm) for wire coating with Siemens motors.

Besides being silent and allegedly energy efficient (which some OEMs say is hard to substantiate), the real advantages of the new gearless motors may turn out to be greater accuracy for better quality film and rolls and space savings where it counts most—in high-layer coextrusion. Addex’s first extruder with a gearless torque motor is called SlimLine (Keeping Up with Extrusion) and is recommended for seven- and nine-layer lines.

High-wood-content profiles

New wood/plastic composite (WPC) profile systems, mostly from Europe, pack in much more wood flour than U.S. processors are used to, and they generally do so without predrying. Cincinnati Extrusion is showing its Fiberex conical (or parallel) twin-screw running 80% wood flour in PP interior profiles, a fairly new application in the U.S.

Cincinnati Milacron will show a TC 86 conical twin for running up to70% natural fiber in fence profiles. Futuresoft’s WPC profile extruders, built in China by a joint venture with Shan Xi Qinchuan Machinery, also reportedly process up to 70% wood flour or rice hulls.

In two-stage WPC extrusion, Advanced Extruder Technologies (AET) combines a continuous batch intensive mixer with a hot-melt extruder. Altech-CTE in Japan combines one long and one short screw side by side, thereby combining a twin-screw kneader in line with a single-screw extruder, all in one barrel.

New flexibility in pipe & profile

Extruders are becoming more modular as an affordable way to offer choices of custom features. Many profile extruders introduced at NPE are described as modular with interchangeable sections, often prewired and pre-plumbed. American Kuhne’snew AKcent low-cost customizable extruder offers a choice of three base configurations. American Maplan’s new TechBEX single-screw profile extruder offers downstream modules that can easily be reconfigured. And Macro Engineering is introducing extruders with interchangeable grooved or smooth feed throats.

Inoex is showing its Advantage here for the first time: It allows pushbutton changes of polyolefin pipe dimensions and is said to be retrofittable on any pipe line. Krauss-Maffei’s QuickSwitch system to change polyolefin pipe dimensions has now been adapted for PVC pipe, too.

MESIM, LISIM, and other cast film news

Even some of the most highly specialized equipment is becoming more flexible. DMT is bringing drawings of its new MESIM (Mechanical Simultaneous Stretching) line for biax film, which is only the second in the world (after Bruckner’s LISIM technology) for simultaneous MD/TD stretching. DMT’s MESIM is designed to accommodate a couple of different materials on one adjustable-width line, either BOPP and BOPE or BOPET and BOPS. Bruckner, meanwhile, is bringing its third-generation LISIM system to the show.

For complex, high-output cast films, Dolci is announcing a 5-layer line with a jumbo chill roll (1.5 meter diam.) and Welex is showing only the die of a 6-extruder, 9-layer line that company sources say is the most complex Welex has ever built—capable of both double-barrier sheet for packaging and pinstriped sheet for yogurt cups.

A lot of market development is going on in micro-layer films with 100 or 1000 layers, but only EDI will reflect that at the show. Cloeren and newcomer Allied Dies have micro-layer developments too, but won’t display them in Chicago.

In other sheet news, EDI is also introducing a Restrictor Bar version of its Contour die for higher sheet throughput. And HPM is featuring Multi-Nip roll stacks with up to seven nipped chill rolls, also for higher sheet output.

More wear & corrosion resistance

With all the glass-filled resins being processed, lots of exhibitors will show more wear-resistant screws and barrels. A few claim to have new metallurgy. Crucible Service Centers is introducing wear-resistant nickel and stainless alloys. Extreme Coatings features a new NiBoride nickel boride coating for abrasion resistance and release in dies. And Conforma Clad is announcing new technology for extreme corrosion resistance.

To help you discern when to repair or replace a screw or barrel in the first place, Glycon Corp. is showing its novel Smart Barrel system, which mechanically measures wear without removing the screw, and Flitescan, which measures screw wear while the extruder is running.

Related Content

Davis-Standard to be Systems Integrator for Novel EDI Flat Die

Die uses motorized lip-adjustment, said to be three to five times faster than heated-bolt adjustments.

Read MoreDie-Lip Adjustment System Relies on Motorized Actuators

Nordson will debut an automated lip adjustment system for its EDI extrusion and fluid-coating dies at the K 2022 trade fair.

Read MoreRoll Stand is Compact, Flexible

Streamlined stack is joined by high-speed extruder; service cart for maintaining screws, dies and rolls; and other products.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More