Which Barrier Screw for You?

It depends ... mostly on the melting requirements of the polymer.

There are many different configurations of barrier screws in use today. Most people think they all work about the same, but in reality there are substantial differences among them. The design of the barrier section is dependent on the thermal, rheological, and physical properties of the polymer. There is no “universal” best design.

There are two principal types of barrier screws: The crossing (or Maillefer) type barrier (Fig. 1) was one of the earliest such designs. Some years later, parallel barrier designs (Fig. 2) were introduced. They are often referred to as the “Barr screw” after noted screw designer Robert Barr.

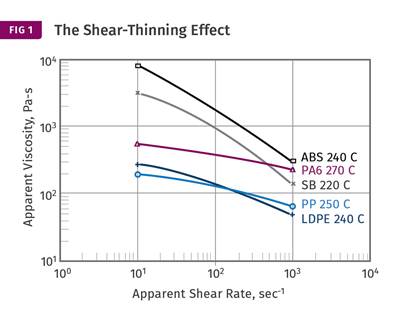

Both designs are still widely used, often for the same polymers, with modifications that often include some combination of each design. For polymers with higher melting requirements, the parallel types generally work better because of the greater melting area in the solids channel for sections of the same axial length. If you compare two 3.5-in. screws with standard pitch and 10 diam. of barrier flight, the parallel design would typically have approximately one-third more area in the solids channel. Since melting capacity is largely proportional to the surface area available for solids melting, it would be expected that the parallel barrier designs would be capable of higher outputs with a good-quality melt for polymers having a higher energy requirement. Those would be polymers having higher melting points, higher specific heats, greater shear-thinning tendency, or a combination of those properties.

Conversely, the crossing barriers would be more suitable for polymers having lower energy requirements. These would be polymers with low processing temperatures, low specific heats, and low shear thinning, or a combination of those properties.

The crossing barrier has no sudden restriction of the solids-channel width at the start of the barrier section. This can be an advantage for hard and/or slippery polymers, as their more fragile solid bed does not as easily reshape to accommodate a change in cross-section. That can cause output, stability, and air-entrapment issues, which can be compensated for in the parallel designs by proper location and design of the barrier start. For the parallel barrier types, features such as an opening into the melt channel to accommodate any early melting; a decompression to compensate for the lost cross-section; and very gradual barrier channel introduction are also used to minimize or eliminate the effect of the geometry change necessary at the start of the barrier and melt channel.

There is even a design originally patented by DuPont that starts the barrier by retarding the main flight pitch to form the barrier channel backward, which has been shown to reduce disruption of the solid-bed formation when that is an important consideration. The crossing barrier style typically has more head-pressure generating capability because of the wider, shallower melt channel compared with the narrow, deep melt channel of the parallel type. As a result, the parallel barrier style usually requires some metering-section length after the barrier section if a significant head pressure must be overcome.

By increasing the lead beyond the standard pitch of the main flight in the barrier section, some improvement in melting area can be made for both the parallel and crossing types. On a 3.5-in. screw, for example, increasing the lead in the barrier section by 25% to 4.375 in. (a 21.7° helix angle) for the main flight, and using the same axial length, results in only 8 turns vs. 10 turns of barrier flight. The increased helix angle will increase the melting area by less than 10% for both types, as shown in Figs. 3 and 4, because of the reduction in turns. Even much of that small advantage is lost as the viscous dissipation or melting per unit length is reduced with the longer helix angle.

The longer helix angle then is more appropriate to get more volume into the barrier section for higher output—but without significant improvement in melting capacity, unless the axial length is increased. Barrier screws of this type have been referred to as the “Dray/Lawrence type” after the inventor Bob Dray. Increased barrier-section lead does reduce issues with the effect of the barrier-flight and melt-channel introduction due to a wider solids channel.

Finally, the exit end of the solids channel for both types can be closed or open. Closed-end channels require that melting is largely completed, or the channel can plug with solids, causing pressure fluctuation, additional screw wear, and lack of thermal homogeneity. Conversely, open solids-channel ends require a design that completes most, if not all, melting before the end of the solids channel—or something else must be done beyond the barrier section to complete the melting. In either case, this requires some complex calculations to get it correct and to provide a large processing window.

ABOUT THE AUTHOR: Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724)651-9196.

Related Content

A Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

Read MoreTunnel Gates for Mold Designers, Part 1

Of all the gate types, tunnel gates are the most misunderstood. Here’s what you need to know to choose the best design for your application.

Read MoreHow to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreThe Importance of Melt & Mold Temperature

Molders should realize how significantly process conditions can influence the final properties of the part.

Read MoreRead Next

What Output Can I Expect?

Processors ask screw designers this question a lot. But neither output nor melt temperature can be predicted without details on the polymer and head pressure.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More.jpg;width=70;height=70;mode=crop)