Why I Still Like Analog Meters

They may not look as slick as their digital cousins, but I find them more helpful in identifying and troubleshooting extrusion problems.

A processor recently sent me a video of a control panel from an extruder that was surging badly, asking me to diagnose the problem. The digital meters were a blur of flashing numbers, and after reviewing the video several times I could not detect any discernible pattern. This reminded me of what I consider a step backward in modern extruder control systems: the use of digital meters for amps, pressure, and screw speed on the extruder and melt pump.

In the “old days,” many extrusion problems could be clarified using analog meters. By comparing the easily interpreted movement of the dial indicator, you could troubleshoot problems such as surging, feed restrictions, poor temperature profiles, melt-pump-related instability and even external inconsistencies. For example, by merely observing the ammeter and head pressure you could troubleshoot melt-channel plugging, poor feeding, and lack of fill. Even unmelt can sometimes be detected on an analog pressure meter located at the end of the barrel.

A plugging surge will show a very rapid amp fluctuation, but a steady head pressure. A feeding surge will show a proportional change in both, but with a time delay as the surge passes through the extruder. A lack of fill in the metering section will show a rhythmic surge with no change in amps. A screw-speed surge when tied to a melt pump can often be diagnosed by observing the suction pressure and screw-speed rhythm. By timing the movement of the analog meter, instability issues can sometimes be tied to things that affect performance but are not even present on the extruder.

With just the help of a stopwatch, factors such as the sequence and influence of hopper loaders, dryers, crammers, stuffers, feeders, regrind variation, and even changing environmental issues in the plant could be investigated with the analog meters.

The digital meters often move so fast that it’s difficult—in some cases impossible—to determine a pattern in the blur of numbers. And different instruments have different update times, making it difficult to compare the time sequence. Analog meters are powered by the function being measured so they act directly and in the same time sequence.

It’s understandable why machine builders now opt for digital meters. They are more compact, more accurate, more adaptable to data collection, and look much more sophisticated. And of course the OEMs do not have to run the extruders.

But the digital meters have actually decreased the ability of the process engineer or operator to diagnose process problems at the extruder. Controls for any process should be designed for optimum utility in operating the process, and not for appearance or remote interpretation of the extruder’s operation. If secondary data issues are important for other reasons, they can be duplicated by redundant meters.

New extruders will generally have digital meters unless you specify otherwise. Ask an experienced extrusion person what kind of meters they like for troubleshooting.

About the Author

Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724)651-9196

Related Content

Cooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreThe Importance of Viscosity in Melting

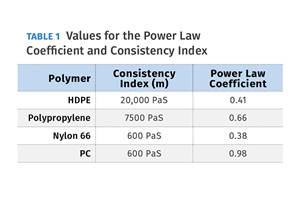

The calculations required to determine the right melt temperature for each polymer are complicated. Knowing the power-law coefficient and the consistency index of the polymer you run might prove useful.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More.jpg;width=70;height=70;mode=crop)