Wood-Plastics Composites Done Right

Troubleshooting

Mixing and extruding wood fiber in a plastic matrix is technically demanding. It requires careful attention to formulation, drying, and extrusion temperatures

Wood-plastic composite (WPC) products were first widely marketed in the early 1990s as weather-resistant decking. The product concept has evolved rapidly into railing, fencing, trim, automotive parts, and other applications. Adding wood to plastic to make WPC reduces the formula cost, raises the modulus of elasticity, and lowers the coefficient of thermal expansion. These benefits come at a cost, however: Extruding wood fiber in a plastic matrix is technically demanding.

Wood is not the only natural fiber used in plastics composites, but it is the most common. Wood used for WPCs is ground, screened, and dried prior to extrusion. For decking and fence profiles, where a rough surface texture is acceptable or even desirable, screening the wood fiber to 40 to 60 mesh results in good flow characteristics and ease of mixing into the plastic matrix.

For railing and other profiles requiring a smooth finish, the wood is screened to 80 to 100 mesh. Fines that pass through a 120 mesh screen are not desirable: These flow poorly and are difficult to distribute evenly in the plastic matrix. Poorly distributed wood fibers, called “wood spots,” are a common quality problem when the wood contains excessive fines or when the extruder is too worn to achieve good mixing.

Ground wood fiber equilibrates at 8% to 12% moisture by weight, depending on the humidity. Residual water in the extrudate leaving the extrusion die causes swelling of the WPC profile, so it is necessary to remove essentially all of the water in the extrudate before it leaves the die and is exposed to atmospheric pressure.

Extruders have devolatilization capability using atmospheric and vacuum venting, but the amount of water that can be removed from a WPC extrudate is diffusion-limited. For counter-rotating extruders, the highest production rates are achieved when the wood fiber is dried to 1% or lower moisture content before being fed into the extruder. Co-rotating extruders achieve better surface renewal of the extrudate than counter-rotating extruders and can tolerate higher wood moisture in the feed. The ideal wood moisture content is in the range of 2% to 4% by weight. Reducing the wood moisture below 2% in the feed for a co-rotating extruder can actually reduce the maximum throughput, because the evolution of steam from the extrudate has a beneficial cooling effect .

Counter- and co-rotating extruders can process wood fiber at moisture levels higher than 1% and 4% respectively, but at the expense of throughput. Reducing the throughput increases the maximum residence time in the extruder, which increases the percentage of water that can be removed from the extrudate. If the amount of water in the wood fed to the extruder is double the recommended levels—e.g. 2% in counter-rotating extruders and 8% in co-rotating extruders—the maximum throughput of the extruder will be roughly halved.

WPC profiles with excess moisture at the die develop localized bubbles, or “measles” under the “skin” of the profile. If the moisture level is high enough, the “skin” will separate almost entirely from the underlying profile as the water vaporizes and expands.

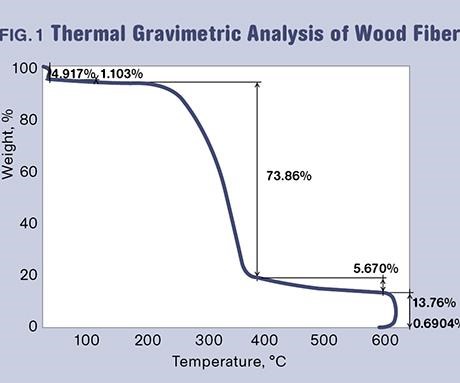

Wood is a complex mixture comprised primarily of celluloses and lignin. This is important in WPC production because celluloses and lignin thermally degrade at temperatures above 190 C (374 F). Figure 1 shows the thermal gravimetric analysis (TGA) of wood fiber, which is a plot of the percent weight remaining of the wood fiber sample versus temperature.

There are two significant mass-loss events in the TGA analysis: loss of water at 25 C to 125 C, accounting for 6.02% of the initial sample weight; and the decomposition of celluloses and lignin between 190 C and 400 C, accounting for 73.86% of the sample weight.

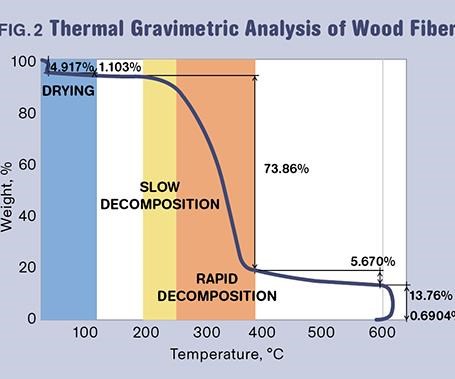

Figure 2 shows the temperature ranges for wood drying, slow decomposition of the celluloses and lignin, and rapid decomposition of the celluloses and lignin.

The difficulty this poses for the WPC producer is evident when considering the standard extrusion temperatures for the plastics commonly used in WPC, shown in the table on p. 34. These are the range of typical melt temperatures seen at the entrance to the extrusion die.

The values in the table overlap almost completely with the temperature range labeled “Slow Decomposition” in Fig. 2. This means that the producer of WPCs is making a profile in which the constituent with the highest weight percentage in the formulation is likely to be undergoing thermally induced decomposition as it enters the extrusion die. Preventing this decomposition—or at best controlling it adequately—poses the greatest challenge in WPC extrusion. Common WPC quality problems arising from thermal degradation of wood are distortions in the extruded profile, known in the industry as “dog-boning,” “swelling,” and “ridging.”

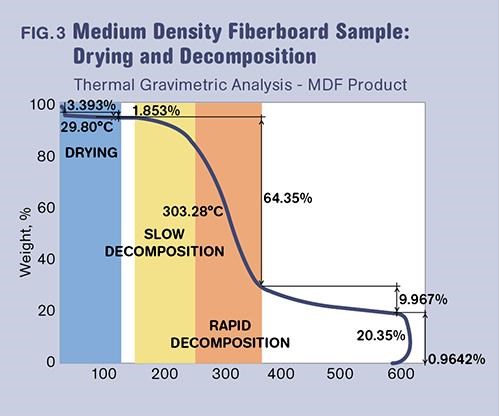

Figure 3 shows the thermal gravimetric analysis of a medium-density fiberboard (MDF) sample. This fiber source was cheap, plentiful, and unsuitable for extrusion. Note that significant mass loss commences at 150 C, probably from the decomposition of a resin or glue used in the MDF process.

THE ROLE OF RESINS

Newcomers to WPC with a background in plastics tend to think “wood is wood.” Newcomers from the wood industry tend to think “plastic is plastic.” In reality, both the fiber and plastic properties are critical to extrusion success.

PVC, polyethylene, and polypropylene are the most commonly used plastics in WPC extrusion. PVC is suited to counter-rotating extruders with low (<50 rpm) screw speeds because it degrades when subjected to high shear or temperatures above the standard processing temperature. PE and PP are better suited for co-rotating extruders because these polymers can withstand higher shear and temperatures than PVC. This allows co-rotating extruders to reach throughputs in excess of 3000 lb/hr (1365 kg/hr) in a machine with a diameter of 103 mm.

Because WPC is a temperature-limited extrusion process, the rough rule of thumb for scale-up is by the square of the diameter of the extruder. For example, given a known throughput of 1600 lb/hr on a 73-mm extruder, the expected throughput of a 103-mm extruder would be (103/73)2 x 1600, or 3185 lb/hr.

PE is the most commonly used plastic for WPCs in the U.S. HDPE is used in WPC applications because it offers better physical properties than LD or LLDPE. HDPE with a melt-flow index between 0.3 and 1 g/10 min, known as fractional-melt-flow grades, are commonly used for WPC decking. Fractional-melt-flow HDPE offers better physical properties than higher-flow HDPEs, but there is a limit on how low a melt flow is practical.

HDPEs with very low melt flows, say less than 0.2 g/10 min, require higher specific energy to process in the extruder. This results in higher melt temperatures. Because the wood in WPCs degrades at temperatures above 190 C, to maximize throughput the WPC producer should choose a plastic with the highest melt flow index that consistently gives the required physical properties in the end product.

VARIATION IN PLASTIC FEEDSTOCK

Plastics are chemically simple, but complex with respect to chain length, chain configuration, molecular-weight distribution, crystallinity, etc. These properties are seldom measured at WPC extrusion plants, but can have a dramatic impact on WPC production.

Much of the plastic used in WPCs is recycled, and another significant fraction is wide- or off-spec virgin material. Because the properties of these streams are not tightly controlled, there can be significant variation in the extrusion process over time. This variation can affect maximum throughput, yield, and scrap rates. Variations in process throughput of ±15% over the course of a few days are not uncommon. These variations can occur at the same frequency as plastic delivery to the WPC production plant. Measuring the melt-flow index of the incoming plastic gives an incomplete but still useful indication of the processing characteristics of the plastics. But even this relatively simple measurement is often lacking at WPC facilities.

WPC production makes significant use of lubricants as a process aid. Lubricants in WPC have two broad functions. The first is minimizing shear heating of the extrudate to limit the melt temperature—known as “internal lubrication.” The second function is to overcome the no-slip boundary condition on the surfaces of the profile die so that the profile has a smooth “skin”—known as “external” lubrication. Lubricant levels in PE-based WPC formulas are typically 3% to 5% by weight. PP-based formulas typically contain 1% to 3% by weight lubricant.

In the largest single market for WPCs—outdoor decking —the mechanical properties of WPCs are important to both the installer and end-user of the product. The product’s resistance to bending under a load, or modulus of elasticity, determines how much structure is needed to support the deck surface and the “feel” of the deck under the end-user’s feet. The product’s resistance to breaking under load, or modulus of rupture, is a matter of end-user safety and long-term satisfaction with the deck installation.

Compared to 100% wood, WPCs have lower moduli of elasticity and rupture. Coupling agents have been developed to improve the mechanical properties of WPCs. The most common coupling agents are maleic anhydrides grafted onto a polyolefin backbone. These work by improving the adhesion of the plastic matrix to the surface of the wood fiber. The benefits of coupling agents must be weighed against increased formula cost, higher specific energy in the extruder, and reduced effectiveness of external lubrication in the profile die.

The use of a capstock layer on WPCs raises the performance of the product in several ways. PE- and PP-based WPCs are relatively soft and have poor resistance to scratching. The wood fiber in the WPC is prone to attack by mold. Colorants, antioxidants, and anti-UV agents are expensive, especially when they are distributed equally throughout the WPC profile when only the surface of the product needs to be colored and protected. A capstock layer of a harder plastic with a concentrated package of additives mitigates all of these problems and greatly improves the performance of the WPC product. However, the benefits of capstocking are offset by the additional complexity and cost of the process.

Related Content

50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read MoreCling Wrap Made from Potato Waste

Australia’s Great Wrap to expand into U.S. with home compostable cling wrap and its refillable dispenser made from recycled PET bottles.

Read MoreMelt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More