World’s First Nine-Manifold Flat-Film Die Up and Running

Feedblock-free technology reportedly cuts thickness variations by two-thirds.

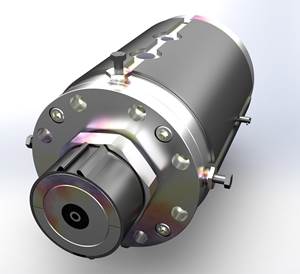

Nordson EDI announced recently that an undisclosed film processors has commissioned a nine-manifold flat die—said to be the first of its kind—to produce nine-layer film from various resins. While the degree of improvement will vary depending on the application, Nordson EDI’s nine-manifold die technology reportedly will reduce variation in individual layer thickness from the ± 15% tolerance often encountered with comparably advanced feedblock systems to ±5%, according to Sam G. Iuliano, chief technologist for Nordson EDI, Chippewa Falls, Wis.

“This greater accuracy achievable with multi-manifold dies enables processors to run thinner layers of the costly specialty materials often required for high-performance packaging films, while at the same time enhancing product quality and consistency,” Iuliano says.

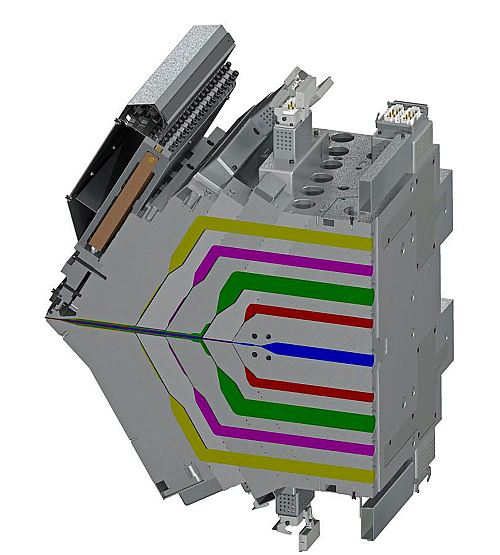

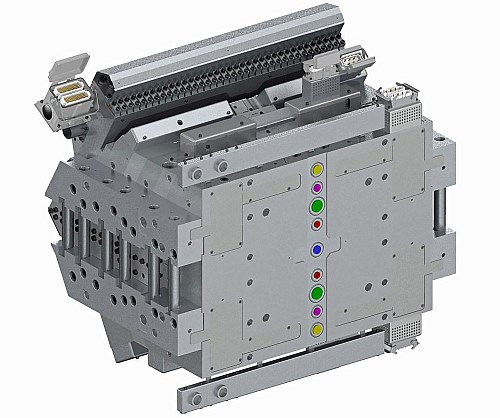

A the firm explains, a manifold is a flow-distribution channel inside the die whose complex internal geometry, engineered for a specific polymer, is designed to develop a uniform, streamlined flow and distribute the material to its full width. In a multi-manifold die, each polymer flow stream has its own manifold, and the layers are combined into a single structure only after each layer has been individually spread to its full width.

A feedblock, on the other hand, combines multiple polymer streams into a narrow multi-layer “sandwich” that is subsequently distributed to full width in a single-manifold die. A chief reason why the multi-manifold method provides greater layer uniformity and thickness accuracy is that it avoids much of the layer-interface deformation that occurs when multiple layers pre-assembled in a feedblock are then spread simultaneously through the die.

“Nordson EDI customers around the world have long benefitted from multi-manifold coextrusion, using dies with two, three, four, or five manifolds,” notes Iuliano. “Engineering a nine-manifold die was a big challenge for us, since 10 major die body segments had to be adequately fastened and heated. In addition, the nine flow channels were each custom designed for the specific layer that they were distributing, meaning that we had to accommodate flow channels of varying sizes and layouts in the design.”

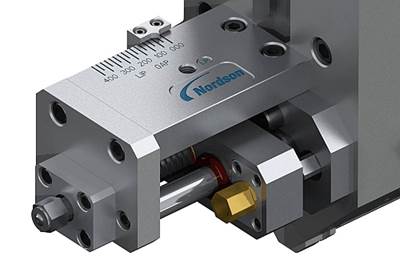

To deliver molten polymer from extruders to a multi-manifold die, Nordson EDI engineers distribution blocks, situated just upstream of the die, in a variety of optional configurations. The simplest versions have a fixed design, delivering the polymer melts to the entrances of the multi-manifold die in only one, dedicated layer sequence arrangement, the company says. More sophisticated distribution blocks provide the ability to re-route melt streams to change the sequence of the layers via exchangeable selector plates. The most advanced distribution blocks, in addition to selector plates, include feedblock sub-assemblies which combine some of the melt streams prior to the die, allowing for product versatility and for a greater number of layers than the number of manifolds that are in the die.

Even as it develops advances in multi-manifold dies, Nordson EDI maintains that it is committed to innovation in feedblock design as well, noted Iuliano states. “Depending on the particular processing scenario, a single manifold die with a coextrusion feedblock may be the best way forward – for example, in a case where the extrusion tooling needs to produce many different structures with vastly different layer ratios. The feedblock approach generally allows for more product versatility as well as simpler cleaning and product changeover procedures. The multi-manifold approach is superior, however, in terms of product quality and consistency. Today, this approach is more than ever a practical, realistic alternative for producers of higher-order multi-layer film.”

Related Content

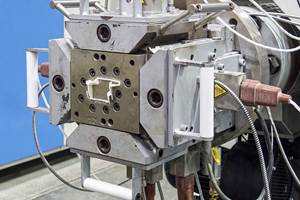

Davis-Standard to be Systems Integrator for Novel EDI Flat Die

Die uses motorized lip-adjustment, said to be three to five times faster than heated-bolt adjustments.

Read MoreIs Your Die Flow Changing Despite Following All the Correct Formulas?

Maybe the problem is that you're starting up with a dry die. Here are tips to solve this issue.

Read MoreBonding, Sintering Tech Advances Metal Bonding for Mold, Die Components

NPE2024: Punch Industry USA exhibits P-Bas, intended to replace the use of 3D printers when producing mold and die components, as well as a variety of mold component supplies.

Read MoreSpiderless Pipe Die Touts Material Savings

Capable of providing a finished extrusion with OD from 2 in.-15 in.

Read MoreRead Next

‘Breakthrough’ Tech Allows for Fast Sheet-Thickness Changes

New system uses a single-point adjustment to change the lip gap and modify the lip land length at the same time.

Read More‘Breakthrough’ Tech Allows for Fast Sheet-Thickness Changes

New system uses a single-point adjustment to change the lip gap and modify the lip land length at the same time.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More