Articles

NPE2024: 10 Things to Do in Orlando

Orlando has a variety of attractions and experiences on offer for those who want to do some sight seeing during NPE2024.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read MoreYour One-Stop Shop for All NPE2024 News

From pre-show coverage to post-show coverage — with at the show coverage in between — you can rely on Plastics Technology to keep you informed on all things related to NPE2024.

Read MoreAutomotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

Read MoreTop 10 Markets for Polyethylene Film Extrusion | #2 Institutional Trash Bags

Editorial director Jim Callari continues his conversation with Mastio & Co. President Kevin Huntsman, on the largest markets for Polyethylene Film Extrusion. Next on the countdown of the largest markets are industrial trash bags.

Read MoreFive Ways to Increase Productivity for Injection Molders

Faster setups, automation tools and proper training and support can go a long way.

Read MoreBreaking the Barrier: An Emerging Force in 9-Layer Film Packaging

Hamilton Plastics taps into its 30-plus years of know-how in high-barrier films by bringing novel, custom-engineered, nine-layer structures resulting from the investment in two new lines.

Read MorePlaces to Eat at NPE2024

If you’re looking for somewhere to eat during your time at NPE2024, check out these restaurants.

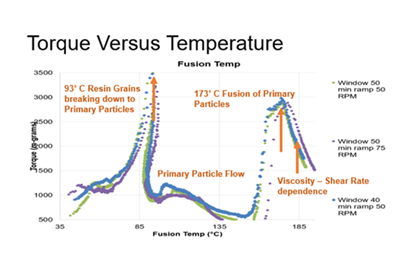

Read MoreTry This Alternate Method for Heating Your Torque Rheometer

Rheometers are generally not on all the time. And most users have found that the first test run in the instrument after heating up is not very reliable and is usually discarded. Try this method instead.

Read MoreWhat You Need to Know About Mold Venting

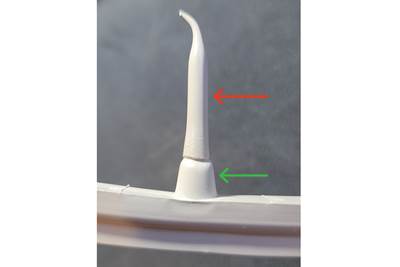

In this three-part collection, Jim Fattori brings to bear his 40+ years of on-the-job experience and provides molders his “from the trenches” perspective on the why, where, and how of venting injection molds.

Read MoreTop 10 Markets for Polyethylene Film Extrusion | #3 Consumer Trash Bags

Next on the countdown of the largest markets for polyethylene film extrusion is consumer trash bags. In this segment of our countdown, we discuss this market as a whole, changes in sustainability efforts, and improvements in production.

Read MoreHow to Design Three-Plate Molds – Part 3

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs — and keep the customer happy.

Read More