Articles

Ultrasonic Welding: Tips, Techniques, and Troubleshooting

In this collection of content, we provide expert advice on welding from some of the leading authorities in the field, with tips on such matters as controls, as well as insights on how to solve common problems in welding.

Read MorePrices Up for PE, PP, PS, Flat for PVC, PET

Trajectory is generally flat-to-down for all commodity resins.

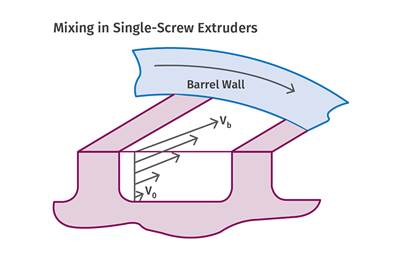

Read MoreSingle vs. Twin-Screw Extruders: Why Mixing is Different

There have been many attempts to provide twin-screw-like mixing in singles, but except at very limited outputs none have been adequate. The odds of future success are long due to the inherent differences in the equipment types.

Read MoreCompounder ‘Walks the Walk’ on Sustainability

Sustainability is one of Techmer PM’s four pillars and guiding principles. And the company has recently earned third-party certification that ensures at least 99% of its waste is diverted from landfills.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreRevisited: A Processor's Checklist for When Business Is Slow

Business slowdowns may provide you with more time for introspection. If you want to take a deeper dive into your operation, here are some things to consider.

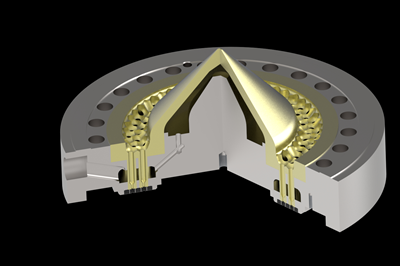

Read MoreHow to Design Three-Plate Molds: Part 2

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

Read MoreClock's Ticking: Register Now for 2023 SPE Thermoforming Conference

Three-day event kicks off Oct. 24 in Cleveland.

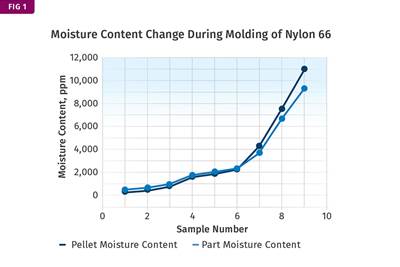

Read MoreWhat's the Allowable Moisture Content in Nylons? It Depends: Part 2

Operating within guidelines from material suppliers can produce levels of polymer degradation. Get around it with better control over either the temperature of the melt or the barrel residence time.

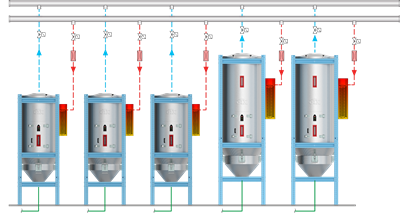

Read MoreHow to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

WatchTop Shops Benchmarking Report: Molding at the Margin

In a world of rising costs and uncertain market conditions, the ability to wring maximum profits from existing business was truly the mark of a Top Shop in 2022.

Read MoreHow to Maintain Pelletizing Quality When Acid Attacks

Developments in the chemistry of polymers and additives have made corrosion a real problem in pelletizers. Here’s how to ward it off.

Read More