Articles

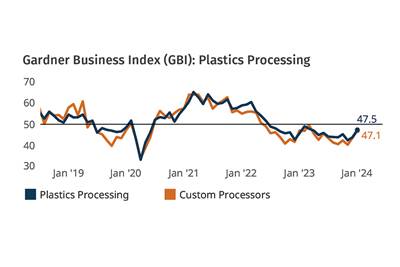

Plastics Processing 'Jumps' into New Year

While still in contraction mode, the index came in at highest level since March 2023.

Read MorePrices of All Five Commodity Plastics On the Way Up

Despite earlier anticipated rollover in prices for most of the volume commodity resins, prices were generally on the way up for all going into the third month of first quarter.

Read MoreHonoring Excellence at NPE 2024: Plastics Hall of Fame

Just before NPE 2024, The Plastics Hall of Fame will celebrate a legacy of innovation and vision for the plastics sector with 17 new members. Discover how these pioneers have helped shape the future of plastics.

Read MoreUpdate Your Image at the Headshot Lounge

Sit for a new headshot at the NPE2024 Headshot Lounge.

Read MoreHow to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

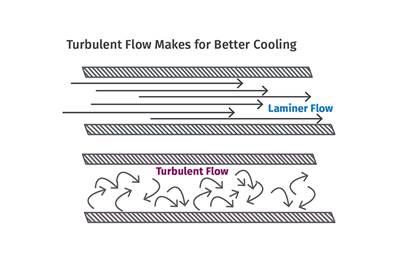

Read MoreMaximize the Cooling Capacity of Your Extrusion Line

Maximizing output in extrusion requires a thorough understanding of not only the cooling requirements of the extruder but of the extrudate as well.

Read MoreGet the Most Out of NPE2024 With Map Your Show

NPE2024 has partnered with Map Your Show to make it easy for you to plan your week.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreImpacts of Auto’s Switch to Sustainability

Of all the trends you'll see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

Read MoreIn the Zone: Materials Science

The Materials Science Zone at NPE 2024 is the place to discover new innovations in materials science and regulatory compliance.

Read MoreIndustry Experts Offer Insights at NPE2024 Packaging Sessions

Learn from industry experts about the latest trends and innovations in packaging at the NPE2024 Packaging Industry Sessions

Read MoreNPE2024 Consumer Products Industry Session Highlights Trends, Innovations

Hear from industry experts about the latest trends in consumer products at the Consumer Products Industry Sessions.

Read More