Articles

Injection Molding Know How: Best of Bozzelli

We at Plastics Technology have been grateful that John has regularly contributed Injection Molding Know How columns to our publication since 2010. In this collection, we present you with five articles that we think you will refer to time and again as you look to solve problems, cut cycle times and improve the quality of the parts you mold.

Read MoreEnjoy Your Weekend in Orlando

Planning to arrive early to NPE2024? Here are some ways to spend your weekend before the show.

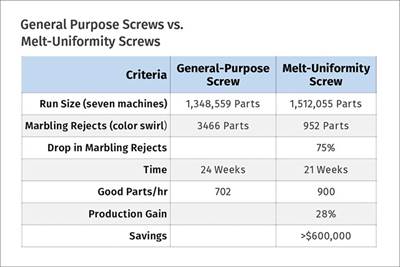

Read MoreImprove Production Rates Via Screw Design — Barrier vs. General Purpose vs. Melt Uniformity

I’m looking for a few good molders to help trial a new screw design, and share data and results for a future article to prove the benefits of a melt uniformity screw.

Read MoreNPE2024 Building and Construction Session Highlights

Learn about industry trends in materials and sustainability with the Building and Construction Industry Sessions at NPE2024.

Read MoreIn the Zone: Bottles

The Bottle Zone is the place to explore cutting-edge bottle and container technologies.

Read MoreNetworking at NPE2024: Take a Sip, Join FLiP

Open to professionals under 40, FLiP and Sip is a free event that includes two drink tickets, appetizers and more.

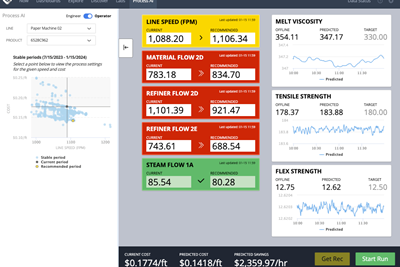

Read MoreUse AI, Machine Learning to Take Variability Out of Manufacturing

Variability has always created insurmountable challenges for manufacturers. However, in the last decade, impact has been more painful due to a lack of experienced workforce. By leveraging technological advancements, particularly in AI, manufacturers can gain a transformative competitive advantage in both cost reduction and workforce development.

Read MoreMake Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

Read MoreNPE2024 Automotive Session Highlights

Learn about trends and innovations in the automotive industry with the Automotive Industry Sessions at NPE2024.

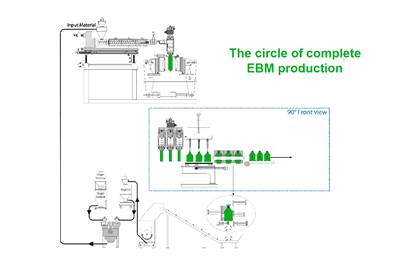

Read MoreGet Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

Read MoreTop 10 Markets for Polyethylene Film Extrusion | #1 Stretch Film

What's the largest market for polyethylene film? Over the last few weeks, Mastio & Co. President Kevin Huntsman has shared their research on the largest markets for Polyethylene Film Extrusion. This week rounds out the top 10 with the largest polyethylene film market: stretch film.

Watch

.png;maxWidth=300;quality=90)