Plastics Extrusion

Extrusion is a continuous process through which parts of a fixed cross-sectional profile are made. Material is fed through a hopper into an extruder, essentially a rotating screw surrounded by a heated barrel, where it is mixed, melted and pumped through a die. The die gives the part its shape. Types include film extrusion, sheet extrusion, pipe, profile and tubing extrusion.

Narrow Your Extrusion Search

ESSENTIAL READING

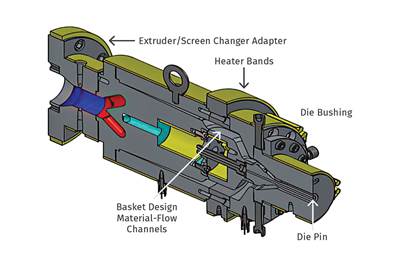

VIEW ALLHow to Select the Right Tooling for Pipe Extrusion

In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative factors. Here’s some guidance to help you out.

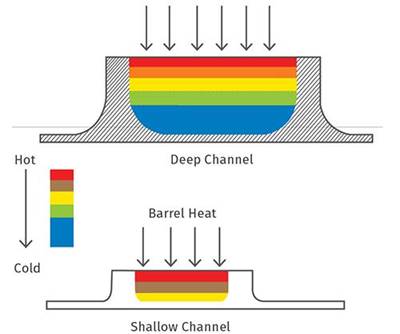

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

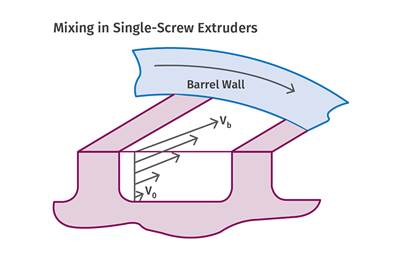

Read MoreSingle vs. Twin-Screw Extruders: Why Mixing is Different

There have been many attempts to provide twin-screw-like mixing in singles, but except at very limited outputs none have been adequate. The odds of future success are long due to the inherent differences in the equipment types.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreLooking to Run PCR on a Single Screw? Here’s What to Keep in Mind

Just drop it in and mix it up? Sorry, there’s a lot more to it than that. Here is some of what you need to consider.

Read MoreWhat to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.

Read MoreLatest Extrusion News And Updates

Downstream Line for High-Precision Profiles

NPE2024: System features calibration and cooling tables, haul-offs, cutting units and tilting tables.

Read MoreCutting-Edge Measurement and Control Devices for Extrusion

NPE2024: Sikora showcasing a range of cutting-edge equipment designed to meet the high standards of the hose, tube and pipe market.

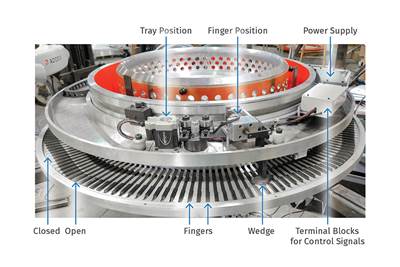

Read MoreCoiling System Features Automated Spool Removal

NPE2024: Designed for wire and cable and tubing, system is equipped with a Yaskawa cobot for automated spool removal.

Read MoreEnhanced Dry-Ice Cleaning Systems for Screws, Tooling

NPE2024: Cold Jet will be displaying four new dry-ice cleaning solutions for screw and tooling, and will also offer booth visitors a chance to win one of them.

Read MoreExtruder Controls Make for More Energy Efficiency

NPE2024: Twin-screw extruders packed with features to optimize energy consumption.

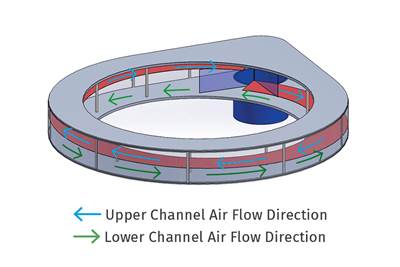

Read MoreSingle-Inlet Plenum Air Ring Improves Gauge Control

NPE2024: New design also eliminates multiple hoses to clean up production area.

Read MoreFeatured Posts

Screw Design Tips to Boost Productivity

In this collection of articles, two of the industry’s foremost authorities on screw design — Jim Frankland and Mark Spalding — offer their sage advice on screw design...what works, what doesn’t, and what to look for when things start going wrong.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreWhat You Need to Know About the Design and Operation of Maddock Mixers

Designed properly, all entering solid polymer fragments and certain types of PE gels entering the Maddock mixer can be trapped and dispersed into the matrix resin. But many are not properly designed. Here’s what to look out for.

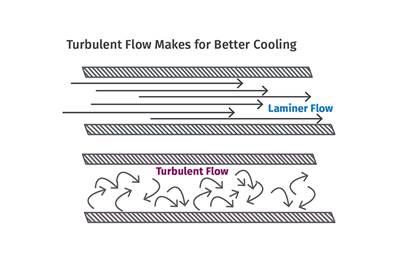

Read MoreNew Blown-Film Cooling Technologies Set to Debut at NPE2024

Cooling specialist Addex to roll out new auto-profiling air ring for rotating dies, and new single-plenum air ring.

Read MoreMaximize the Cooling Capacity of Your Extrusion Line

Maximizing output in extrusion requires a thorough understanding of not only the cooling requirements of the extruder but of the extrudate as well.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreFAQ: Extrusion

However, there are actual limits on increasing output as L/D is increased. Usually these limits are due to the inability of the feed section to deliver more polymer. On smaller-diameter screws, that limit often is determined by screw strength. On small screws you can only go so deep in screw channels before the screw is over torqued and fails. On larger extruders, the efficiency of feeding decreases as the channels get deeper until there is no further increase in output.

There are four main things to consider in selecting the correct stack for your application: the overall cooling capacity, the products to be processed, the mechanical capability, and the rolls’ internal design. Considering just the cooling capacity, the top roll is there to set the sheet thickness as well as its uniformity.

One of the most useful evaluations is the relatively simple calculation of drag flow. Drag flow is simply half the volume of one turn of the metering section per second at a specific screw rpm, which, when multiplied by a units conversion and the melt specific gravity of the polymer, is a very accurate approximation of the output in lb/hr at no head pressure.

Extrusion Supplier Categories

- Web Winders, Unwinds, Rewinds

- Single-screw Extruders

- Saws

- Orientation and Tentering Equipment (for Webs)

- Pipe Corrugators

- Slot Orifice Coaters

- Extruder Screens, Screen Packs, Screen Changers, Breaker Plates, Other Melt-Filtration Equipment

- Sheet Take-off Systems

- Film Take-off Systems

- Web Brakes, Clutches, Chucks

- Extrusion Dies

- Pipe Bellers

- Web Inspection Systems

- Pipe Take-off Systems

- Web Guides, Edge Detectors

- Wire and Cable Take-off Systems

- Pipe Thickness Measuring Equipment

- Roll Coaters

- Dispensing Equipment for Reactive Resin Systems

- Melt Pumps for Extrusion

- Curtain Coaters

- Profiles, Tubing, Hose Take-off Systems

- Calenders

- Cutoff Equipment

- Plastic Lumber Extrusion/Molding Systems

- Web Slitter/Rewinders

- Knife Coaters

- Film, Sheet, Coated Web Thickness Measuring Equipment

- Web Tension Controls

- Multiple-screw Extruders

- Web Cleaning Equipment

- Coextrusion Dies, Feedblocks

- Web Slitters

- Plasma Coating Systems

- Ram Extruders

- Air Knife Equipment

- Monofilament/Multifilament Take-Off Systems

- Rotary Screwless Extruders

- Pelletizers

- Solution Casting Equipment (for Film)

- Air Rings and Internal Bubble Cooling Units

- Profiles, Tubing, Wire Thickness Measuring Equipment