2019 SPE Auto Innovation Award Winners Shined with Several 'Firsts' and Broad Transferability

Making its mark, additive manufacturing had its own category for the second year and was used in the winner of the aftermarket category.

The 49th annual Automotive Innovation Awards Competition was celebrated on Nov. 6, by the Automotive Division of the Society of Plastics Engineers (SPE) at its gala in Livonia, Mich., with the unveiling of the winners of nine categories. The winners of all categories exemplify continued innovation and transferability in the use of plastics.

This competition is the oldest and largest event of its kind in the automotive and plastics industries. Dozens of teams made up of OEMs, tier suppliers, and polymer producers submit nominations describing their part, system, or complete vehicle and why it merits the claim as the Year’s Most Innovative Use of Plastics. The event typically draws over 700 OEM engineers, automotive and plastics industry executives, and media. Funds raised from this event are used to support SPE educational efforts and technical seminars, which help educate and secure the role of plastics in the advancement of the automobile.

For this editor, along with Gardner Business Media sister publications’ colleagues Composites World’s Jeff Sloan and PT Mexico’s Natalia Ortega, it was once again an honor to serve on a panel of Blue Ribbon judges in this well-recognized event.

Here’s a brief look at the nine winners, starting with the grand award winner—also the winner of the Body Exterior category. Other finalists in the various categories that merit attention will be highlighted in future blogs.

Body Exterior/Grand Award Winner: Composite Pickup Box

This is industry’s first pickup box in carbon-reinforced thermoplastic composite. It saved 62 lb/28 kg; provided best-in-class impact resistance/durability; and the unpainted UV-stable material eliminated the need for a bedliner, which saves another 40 lb/18 kg. Moreover, numerous customer features were molded in, including functional compartment dividers and motorcycle tire pockets. The ability to achieve a deeper draw during molding increased cargo capacity. Significant technical challenges were overcome due to use of novel materials, processes, coatings and joining methods. The box is fully recyclable and some scrap is reused on the vehicle.

▪ OEM Make & Model: 2020 General Motors Co. GMC Sierra LD FST pickup

▪ Tier Supplier / Processor: Continental Structural Plastics/Continental Structural Plastics

▪ Material Supplier / Toolmaker: Teijin Ltd./Paragon D&E, Model Die & Mold, Inc., Altron Automation, & Legacy Industries

▪ Material / Process: Sereebo A235Y carbon fiber-reinforced nylon 6 sheet / Compression Molding

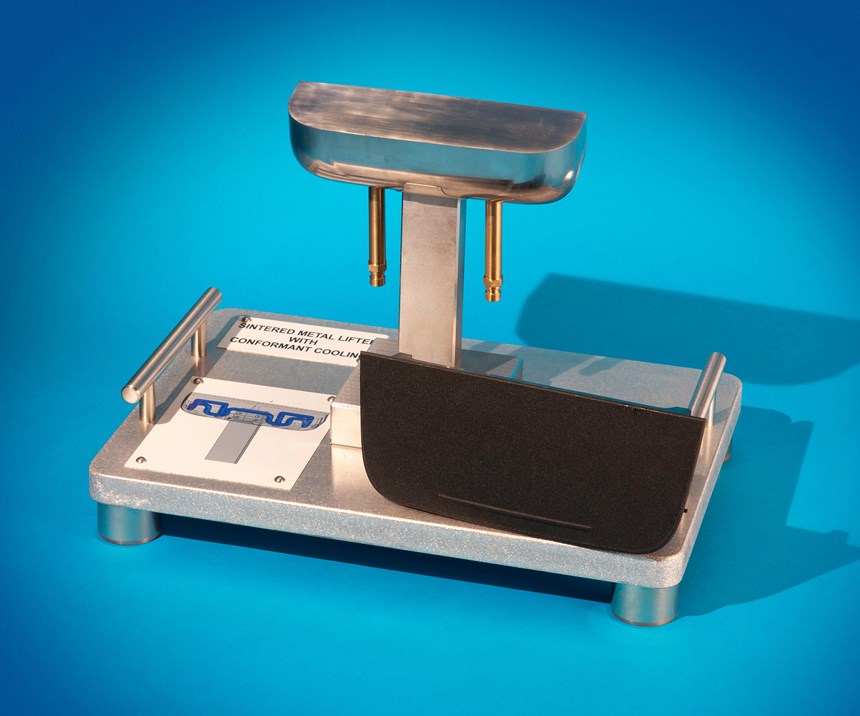

Additive Manufacturing: Sunglass Bin

Additive Manufacturing was used to produce a single tooling insert (lifter) that replaced two conventionally machined lifters to mold an injection molded sunglass stowage bin. This process enabled design changes to produce a deeper pocket with a heavier undercut that still could be molded without hotspots, warpage, or demolding issues and without needing to switch to a more costly resin. The new deeper bin design also better meets customer requirements while reducing cycle time, molding scrap, tooling maintenance, and improving dimensional stability in the final part.

▪ OEM Make & Model: 2020 Ford Motor Co. Ford Explorer SUV

▪ Tier Supplier / Processor: Methode Electronics, Inc. / Methode Electronics, Inc.

▪ Material Supplier / Toolmaker: Celanese Corp. / RGM Tooling Consultants, Inc.

▪ Material / Process: Celstran PP-GF20-02 LFT-PP / Injection Molding; 3D Printed H13 Steel

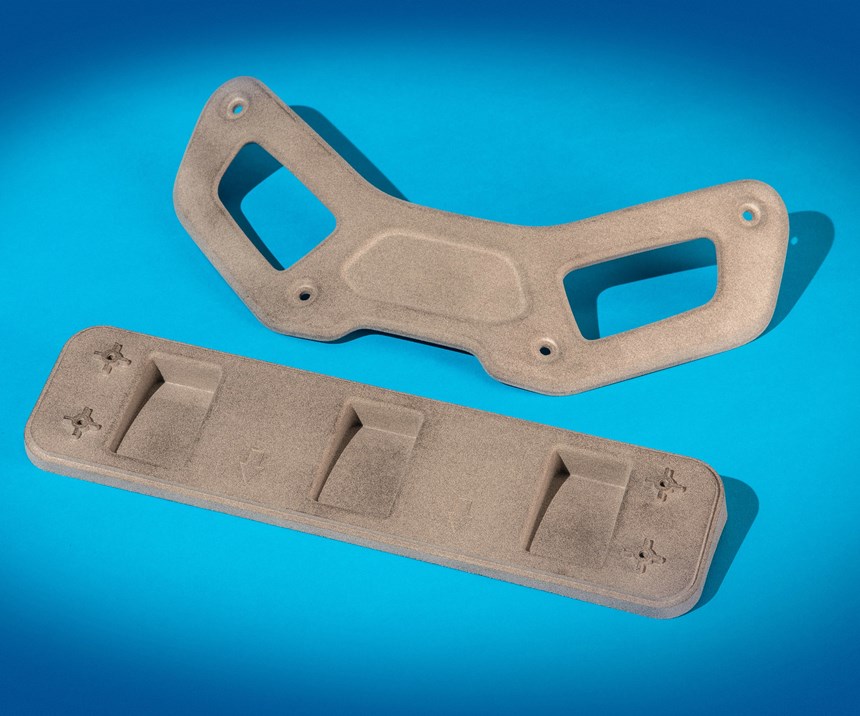

Aftermarket and Limited Edition/Specialty Vehicles: Multiple Additively Manufactured Components

Additive manufacturing proved the most efficient and cost-effective method for producing 19 parts on this high-performance sedan whose total build volume will be limited to 300 cars. Both development and production parts were produced on the same printer platform, which eliminated significant tooling investment (est. at $123,000), as well as storage and maintenance costs. All 19 parts print at one time in a kit, and multiple kits can be produced at the same time. Additionally, parts offer better bonding adhesion than conventionally produced parts and passed paint adhesion tests.

▪ OEM Make & Model: 2020 Jaguar Land Rover Ltd. Jaguar XE SV Project 8 supercar

▪ Tier Supplier / Processor: HP Inc. / Jaguar Land Rover Ltd.

▪ Material Supplier / Toolmaker: HP Inc., DyeMansion GmbH / N/A

▪ Material / Process: HP High-reusability PA 12 / HP Multi Jet Fusion

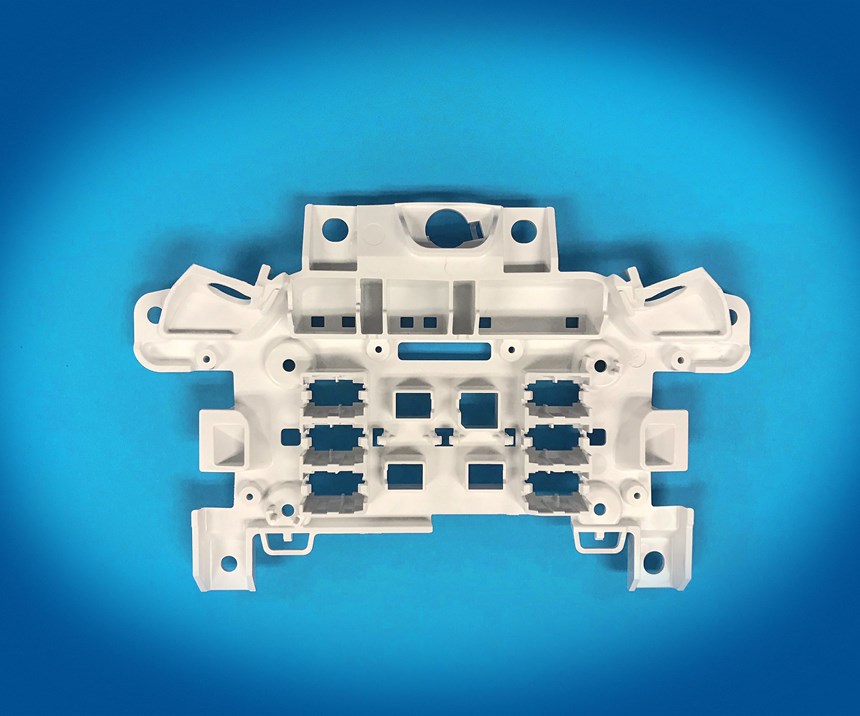

Body Interior: Integrated Button Carrier Modular Strategy

To reduce overhead console complexity, a new design was developed that integrated mechanical, lighting, electrical, and safety functions into a single modular button carrier injection molded from MIC PC/ABS. With all program variants, this reduced part count from 70 to 17/vehicle, achieved a $7 cost savings/vehicle and $1.42-million program savings for tooling and testing. No button binding issues have been seen, BSR (buzz, squeak & rattle) was improved, and the headliner fit better. To date, two patents have been filed and one has been granted on this technology.

▪ OEM Make & Model: 2020 Ford Motor Co. Explorer/Aviator/Corsair SUVs

▪ Tier Supplier / Processor: Methode Electronics, Inc. / Methode Electronics, Inc.

▪ Material Supplier / Toolmaker: The Materials Group / RGM Tooling Consultants, Inc.

▪ Material / Process: Opticarb 8085SE PC/ABS / Injection Molding

Chassis/Hardware: Rear-Differential Front Bracket

A critical diecast and machined aluminum bracket was replaced by an injection molded bracket in 50% glass-reinforced nylon 66 in this demanding rear differential module. The composite material was not only 30% lighter and saved $1/car direct costs vs. the benchmark aluminum, but its matrix provided tenfold higher damping, improving NVH performance, and it fit current packaging space for this running change. The part passed all performance and durability requirements, eliminated corrosion issues, and will significantly reduce tooling costs over the life of the program.

▪ OEM Make & Model: 2020 FCA NA LLC Jeep Cherokee SUV

▪ Tier Supplier / Processor: Boge Rubber & Plastics / Boge Rubber & Plastics

▪ Material Supplier / Toolmaker: BASF Corp. / N/A

▪ Material / Process: Ultramid A3WG10CR 50% GR-Nylon 66 / Injection Molding

Environmental: 100% PCR Carbon Canister Housing

The PP backing from PCR carpeting is given another life by being recycled back into the injection molded carbon canister housing for passenger cars. This is the first 100% PCR PP-based carbon cannister. By replacing virgin PP, the recycled resin reduces cost 25% with no sacrifice to processing or molded-part performance, but increases sustainability. It is currently being rolled out on more than 20 Ford programs globally.

▪ OEM Make & Model: 2019 Ford Motor Co. Ford Mustang Sports Car

▪ Tier Supplier / Processor: Delphi Technologies PLC / MGS Mfg. Group

▪ Material Supplier / Toolmaker: Wellman Advanced Materials / MGS Mfg. Group

▪ Material / Process: EcoLene PP8004-BK1 20% GR-PP / Melt Compounding & Injection Molding

Materials: Glass Wool-Reinforced Composites for Improved Scratch Resistance

To improve both long-term scratch resistance and dimensional stability in injection molded PP interior trim panels, glass wool (crushed glass + sand produced from reclaimed/PIR building insulation) was used to replace talc, whiskers, and fiberglass. Because glass wool boosts mechanical properties vs. talc, filler content was reduced 5%, leading to lighter, less costly parts. Since it helps maintain surface finish longer, it should lower warranty claims. A unique process was developed to incorporate glass wool into the resin compound. Glass wool is difficult to dispose of, so this application gives it another use life.

▪ OEM Make & Model: 2017 Hyundai Motor Co. Hyundai Elantra sedan

▪ Tier Supplier / Processor: Seoyon E-Wha / Seoyon E-Wha

▪ Material Supplier / Toolmaker: Daehacom Co., Ltd. / Seoyon E-Wha

▪ Material / Process: SW920 SA glass wool-reinforced PP / Injection Molding

Powertrain: Transmission Gear Shroud

A new transmission gear shroud cover and base protect the drive gear so it rotates freely without needing to push through transmission fluid, lowering effort, improving pump efficiency, and increasing vehicle MPG and the effective life of the transmission fluid. Injection molded TPC-ET replaced earlier steel covers with rubber seals that were heavier, more complex and costly, and suffered from more variation. Very aggressive snap fits permanently join cover to base once the assembly is completed. The same material molded very-thin provides a ductile seal. Costs were reduced 22%, weight lowered 65%, and NVH was improved.

▪ OEM Make & Model: 2017 Ford Motor Co. Ford F-150 pickup

▪ Tier Supplier / Processor: Stackpole International / MacLean-Fogg Co., Engineered Plastics Components Inc.

▪ Material Supplier / Toolmaker: DuPont de Nemours, Inc. / Gibson Automation

▪ Material / Process: Hytrel 8238 TPC-ET / Injection molding

Process / Assembly / Enabling Technologies: Rear Bumper

The auto industry’s first pultruded curved bumper beam uses the unique radius-pultrusion process and equipment to achieve a hollow beam with central web in carbon fiber fabric-reinforced polyurethane/acrylate resin. The curved geometry was desired to better match rear styling and vehicle package space. The beam features an integral tow hook mounting and is assembled to the body-in-white (BIW), requiring excellent mechanicals at elevated temperature. The beam meets low-speed crash requirements while cutting mass by 4.9 lb/2.2 kg vs. a metal-inert gas (MIG) welded aluminum extrusion. 3D printing was used to produce mandrels to maintain the hollow interior.

▪ OEM Make & Model: 2020 General Motors Co. Chevrolet Corvette sports car

▪ Tier Supplier / Processor: Shape Corp. / Shape Corp.

▪ Material Supplier / Toolmaker: SGL Carbon SE, VectorPly Corp., Scott Bader Co. Ltd. / Thomas GmbH + Co. Technik + Innovation KG

▪ Material / Process: Crestapol 1250 PUR-acrylate reinforced with CF / Radius-Pultrusion

Related Content

Melt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Read MoreThe Effects of Time on Polymers

Last month we briefly discussed the influence of temperature on the mechanical properties of polymers and reviewed some of the structural considerations that govern these effects.

Read MorePrices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.

Read MoreThe Effects of Stress on Polymers

Previously we have discussed the effects of temperature and time on the long-term behavior of polymers. Now let's take a look at stress.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More