A True Pioneer Passes

Sheet extrusion legend Frank Nissel dies.

I was saddened earlier this week to learn of the passing of Frank Nissel, who revolutionized the sheet extrusion business when he co-founded Welex in 1966, and was elected to The Plastics Hall of Fame in 2000 during NPE. Frank passed away Thursday, Aug. 28. He was 89.

I remember the first time I met Frank. It was in 1988. I had just joined the now-defunct Plastics World Magazine as senior editor in charge of reporting on extrusion. I didn’t even know what extrusion was at the time. My boss back then, current plastics blogger Doug Smock, explained it to me this way, to my recollection: “In extrusion, plastic pellets are melted and conveyed by a rotating screw through a die to form a part.” A light bulb went on over my head that would soon be extinguished. I replied, “Oh I get it, so the plastic is somehow colored?” “No,” Doug said. “It’s not d-y-e, it’s d-i-e.” I’m not sure if learning that made matters better or worse in my mind. Was extrusion a process where plastic pellets went to die?

So with that “background,” I was soon off to Blue Bell, Pa. to meet this regal, larger-than-life figure that I had heard a little bit about beforehand. I don't know how tall Frank was. Maybe 6 ft or a bit more? But he seemed a lot bigger. When he stood up his back was perfectly straight, his shoulders were thrust back, his shirt was crisp and his suit immaculate. I remember thinking, "This guy is a giant."

I was not working on an article about sheet when we met, as I recall; I just wanted to sit down and talk with someone who knew stuff and pick his brain. Pick his brain? Who was I kidding? I was scared. I knew nothing, didn't even know what questions to ask, and realized I wouldn't understand the answers anyway. And I had heard that Frank, well, could be a bit intimidating and didn't suffer fools gladly.

But Frank could not have been more accommodating. He was pleasant, charming, friendly, and funny. Very funny. He called me Mr. Callari, which was disarming and immediately put me at ease. And he was patient. (I came to discover later that he wasn't always patient!) I learned more about his personal trials and tribulations, his outside hobbies and interests, and his opinions about this and that (including plastics magazines and editors) during that meeting than I did about the nuts and bolts of sheet extrusion. But that was more because a lot of the technical stuff he told me went over my head. Somehow he realized that (I guess it was the glazed look in my eyes), teased me about it, waved his hand and suggested that I close my notebook, told me to relax and assured me that at some point sooner or later some of this extrusion mumbo-jumbo would make sense to me (later, as it happens) if I kept at it.

One thing I found out soon enough was that a lot of people in a lot of places all over the world had his equipment. "That article you wrote about (so and so)...100% Welex," he'd quip.

Over the years, meeting at his office, at trade shows, at SPI/SPE events, Frank and I became friendly. Oh, he'd poke me every now and then about this article or that, but Frank was one of those guys who once he decided he liked you…that was that. He enjoyed pulling my leg. "What’s new?” he’d ponder, repeating my question. “We painted our machines a different color. Write about that.” But he was truly a font of information about anything related to polymers and processing, and not just extrusion either. "I read that article you wrote last month," he'd say. "That (whatever) that you reported was new is actually about 25 years' old. It didn't work then, it won't now."

Excuse the cliches, but Frank was in no uncertain terms an industry icon, a legend, a pioneer, a giant, an immortal. Frank was to the world of extrusion what Robert Schad has been to the world of injection molding. Now, if God has any questions about seven-layer sheet extrusion for thermoforming drinking cups, he knows who to ask. Heck, they might be stringing up a line now.

Related Content

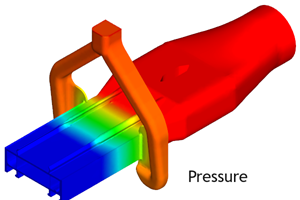

Updated Software Reduces Die Design Iterations

New software said to reduce the number of fine-tuning iterations and die development time by at least 50%.

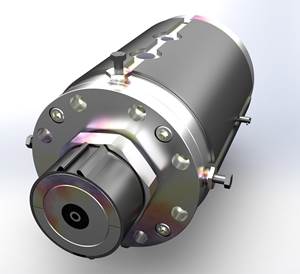

Read MoreCrosshead Die for Elastomers Adjusts Easily

NPE2024: Mechanically actuated gum space adjustment requires only ordinary socket wrench.

Read MoreSpiderless Pipe Die Touts Material Savings

Capable of providing a finished extrusion with OD from 2 in.-15 in.

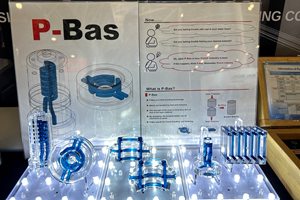

Read MoreBonding, Sintering Tech Advances Metal Bonding for Mold, Die Components

NPE2024: Punch Industry USA exhibits P-Bas, intended to replace the use of 3D printers when producing mold and die components, as well as a variety of mold component supplies.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More