Additive Mfg Machinery 'Giants' Broaden Scope Through Acquisitions

Stratasys and 3D Systems are evolving into all-encompassing providers in the additive manufacturing business arena.

Vertical integration seems to be the order of the day with additive manufacturing machinery lead players Stratasys and 3D Systems, as they evolve into companies that are all-encompassing providers in this business realm—from materials, to machinery, to service bureaus. Here’s the latest from both:

Stratasys announced in early April, that it had entered into definitive agreements to acquire two privately-held additive manufacturing service bureau companies, Solid Concepts Inc. and Harvest Technologies. The former is the largest independent such service bureau in North America and a fast-growing partner to RedEye, Stratasys’ existing digital manufacturing service business. Completion of these transactions is expected within the upcoming third quarter and both entities will be combined with RedEye to establish one additive manufacturing services business unit.

With the combined business unit, Stratasys is creating a leading strategic platform focused on meeting customer additive manufacturing needs through expanded technology as Solid Concepts and Harvest Technologies bring to Stratasys significant manufacturing and end-use parts production capabilities, infrastructure, capacity and process knowhow, which are expected to accelerate and enable further adoption of additive manufacturing. The combination of Solid Concepts extensive knowledge of manufacturing and vertical focus, such as medical, aerospace, and industrial,and Harvest Technologies’ experience in parts production as well as materials and systems knowhow, together with RedEye, strengthen Stratasys’ direct digital manufacturing and parts production expertise. The company expects to expand into a broad range of capabilities and applications expertise across a wide range of new and existing applications.

In a different move, Stratasys has also announced it has entered into a definitive asset purchase agreement to acquire certain assets of Wisconsin-based Interfacial Solutions. This provider of thermoplastics R&D and production services, has been a production partner to Stratasys for its FDM product lines over the past three years and has been instrumental in the R&D for, and the producer of, some of Stratasys’ thermoplastic materials.

Interfacial Solutions’ significant expertise in plastics and filament, will accelerate Stratasys’ materials development efforts for all FDM platforms, including MakerBot, allowing the company to bring new materials to the market faster, says Stratasys CEO David Reis. “The acquisition is expected to accomplish three objectives, which include strengthening our materials R&D skills and bandwidth; enabling us to become vertically integrated in materials development and manufacturing; and increasing materials production space and capacity.”

3D Systems, meanwhile, announced mid-month that it was set to acquire a majority interest in Brazil-based Robtec, the largest service 3D printing/additive manufacturing service bureau in Latin America and the leading distributor of printing and scanning products in the region. One of 3DS’ earliest such acquisitions was in late 2009, with the purchasing of Acu-Cast Technologies, a provider of additive manufacturing services which was then integrated into 3DS’s Rapid Manufacturing Centers to form a global 3Dproparts service for rapid prototyping and manufacturing with online quoting and ordering and same-day shipping.

3DS has, in fact, made nearly 50 acquisitions in the past four years, and this Brazilian service bureau is at least the sixth since December. Many have been technology companies that 3D Systems acquires in an effort to serve as many markets as possible, and this latest acquisition stretches the company’s geographic reach. One such example, is this month’s acquisition of Medical Modeling Inc., a leading provider of personalized surgical treatments and patient specific medical devices, including virtual surgical planning and clinical transfer tools, using 3D modeling and printing that is rapidly changing how reconstructive surgery is done today. The company pioneered the field of 3D printing-centric personalized surgery and patient-specific medical devices with FDA-cleared manufacturing processes and world-class expertise, providing help to tens of thousands of patient cases for surgical planning tools, implants, and other design services. 3DS plans to consolidate all of its healthcare activities into a single unit under the leadership of former Medical Modeling president, Andy Chistensen, now v.p. of personalized surgery and medical devices.

On the materials front most recently, 3D Systems acquired Village Plastics, a manufacturer of filaments based on ABS, HIPS, and PLA biopolymer for 3D printing and has now integrated its materials and manufacturing technologies to accelerate development of advanced filament-based materials.

Related Content

Additive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.

Read More420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

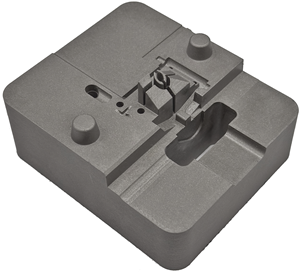

NPE2024: Mantle's Additive Manufacturing Technology is Designed for Precision Tooling

Read MoreLarge-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read MoreProduction Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.png;maxWidth=300;quality=90)