Along with Sustainability, Advancements in Materials & Additives to be Highlighted at K 2019

Expect to see new materials and additives address sustainability but also emerging and growing technologies such as electrification of vehicles.

Once again, I had the pleasure of attending a pre-K show event in Belgium organized by the international communication consultancy EMG. It was one of several such events which take place every three years just a few months ahead of each K show. Our group of trade media attendees was treated to an interesting excursion to Antwerp, Europe’s second largest shipping port. It included a tour of a previously derelict fire station which was repurposed, renovated and extended into a new headquarters for the port, as well as a lovely dinner boat ride.

Presentations from seven key materials and additives suppliers gave us a pretty good glimpse of what to expect at K 2019. As is the case with my colleagues who attended other such events that included leading equipment and other materials suppliers, sustainability and the circular economy were dominant themes at the Belgium event. As you can see by each company’s highlights below, in addition to some introductions of recycled content materials and other sustainable products, there are new advancements in materials and additives designed to meet emerging and growing technologies such as electrification of vehicles.

▪ This presentation started with a discussion on solutions in sustainability, and company officials stressed that the company’s activities toward a circular economy for plastics include innovation, new product development, and industry partnerships.

▪ PP Global Business Director Lada Kurelec discussed new innovations aimed at reducing weight and increasing performance such as Cohers S polyolefin plastomer and UMS expandable PP.

▪ Global Business Leader for Engineering Thermoplastics Markestein discussed new product concepts aimed as vehicle electrification including new PC and PP solutions.

▪ The company will also showcase new material solutions for energy-efficient homes at K 2019.

INEOS Styrolution

▪ The company is active in exploring various avenues toward achieving circular styrenics solutions. This includes their recent announcement on PS chemical recycling technology.

▪ At K 2019, the company will showcase new recycled-content PS grades, its expanded Skylight styrenic composites, and a new high-flow ABS.

▪ This presentation started with a discussion of the nylon 66 market, noting that growth of 2-3%/yr will increase over the next 4-5 years as electrification of cars grows.

▪ Company officials discussed capacity increases in intermediates (ADN) which will alleviate nylon 66 tightness/shortages. .

▪ Highlighted at K 2019 will be the expansion of high-temperature nylons for automotive.

▪ The company will launch its first family of long-chained nylon 66 grades which will be targeted to automotive extruded fuel and brake lines.

▪ Also to be launched, a new family of flame-retardant nylon 66 grades for electrical applications.

▪ Also new will be nylon 66 nano fibers for filtration such as air filters and equipment filters as well as textiles.

▪ Ascend will also add recycle-content nylon 66 grades to meet increasing demand by customers.

DSM Engineering Plastics

▪ DSM’s will highlight its new additive manufacturing business unit. The company is positioning itself as a materials provider for all additive manufacturing processes.

▪ DSM is focusing on EMI shielding and the future of metal replacement in electrical cars focused on electrification and high-voltage charging trends. Look for new materials.

Clariant

▪ De-demonizing plastics will be Clariant’s key theme.

▪ The company’s Ecotain sustainability label will now cover all of its products—over 200 additives, masterbatches and compounds across all business units.

▪ The company discussed ‘a symphony of collaborations’ with the aim to move away from the linear industrial chain and into a circular economy. At K 2019, Clariant will highlight a 3-part platform toward a circular economy—new products, partnerships with players in recycling ecosystem, and knowledge gained across the value chain.

▪ New products to be launched include: a new oxygen scavenger for PET; an additive that reduces odor in recycled plastics; and, an automated dosing systems for liquid colors.

▪ Also, the company will launch three new black pigments.

▪ Clariant will highlight its collaboration with a software provider to come up with a color matching program for post-consumer recycled material.

▪ Also new, pigments designed for coloring biodegradable plastics.

▪ A new halogen-free flame retardant that retain FR performance after the material is recycled will also be highlighted.

▪ Newly appointed chief sustainability officer addressed Songwon’s activities and involvement in this arena, highlighting examples of sustainable packaging & label printing activities.

▪ As part of its existing innovative polymer stabilizers and PVC additives, the company is developing a line of halogen-free flame retardants that will be launched at K. Marking the company’s entry in the FR business, Songwon, says its new flame retardant synergists have potential to reduce the amount of flame retardant needed in both halogen and non-halogen formulations.

Perstorp

▪ Company will unveil Pevalen Pro, a new renewable polyol ester non-phthalate plasticizer for producing flexible PVC with a lower carbon footprint. Second generation Pevalen Pro allows for up to 40% renewable content in flexible PVC.

▪ Company will make a case on PVC use and how to boost its sustainability through the use of non-phthalate additives.

Related Content

Masterbatches Reduce Gloss in PLA and PETG 3D Printed Products

Insight Polymers & Compounding’s two low-gloss additive masterbatches shown to boost appearance of 3D printed objects.

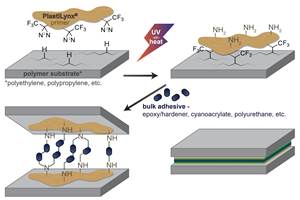

Read MoreSurface-Activating Primer for Polyolefins and Fluoropolymers

XlynX Materials’ PlastiLynx is designed for use with low-surface-energy polymers for improved bonding and printing.

Read MorePFAS-Free Processing Aid for Blown Film Extrusion

Ampacet’s new processing aid said to perform as well as fluoro-based PPAs in blown film.

Read MoreCrosslinking Process Promises Thinner, Higher-Performance PE Films

Technology combines UV curing system with photo initiator promoter masterbatch.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More

.png;maxWidth=300;quality=90)