Alpine Kicks Off K With Lots of Layers

Layers are great with chocolate cake. And blown film too. Hosokawa Alpine ran what’s believed to be a show first: an 11-layer line producing nylon-based barrier film.

Layers are great with chocolate cake. And blown film too. Hosokawa Alpine ran what’s believed to be a show first: an 11-layer line producing nylon-based barrier film.

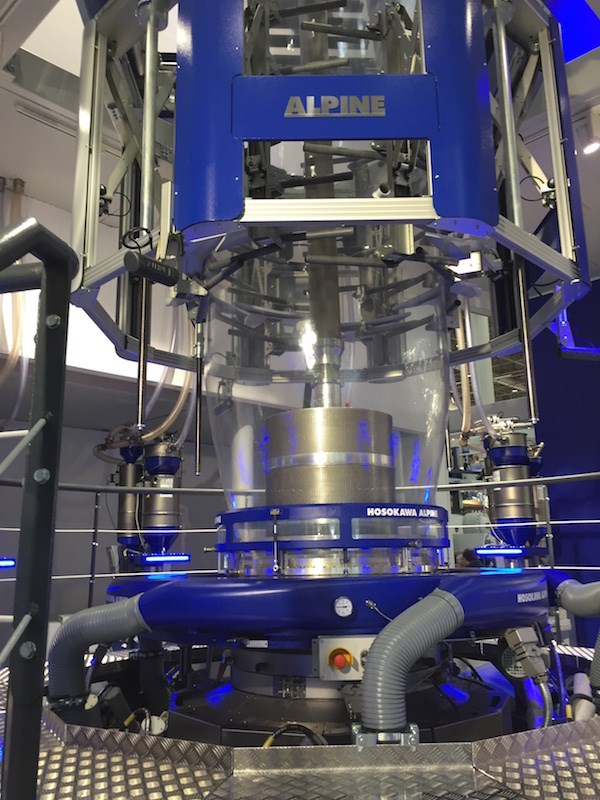

Over the past few K Shows most suppliers have stuck with five-layer structures. Back in 1998, Battenfeld Gloucester, now part of Davis-Standard, ran a seven-layer nylon-barrier blown film line at K. At K 2010, Reifenhauser ran a nine-layer line. The system Alpine fired up on Day One of K 2016 featured 11, grooved-feed 65-mm, 32:1 L:D water-cooled extruders and a 560-mm X Die, as well as a new version of its V air ring designed to maximize output.

It was equipped with a film-stretching unit built into the nip. The line offers “infinite flexibility by allowing processors to bundle 11 equal layers” in the configuration of their choosing, says Dave Nunes, president of the company, whose U.S. operation, Hosokawa Alpine American, is based in Natick, Mass.

Related Content

-

Formulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

-

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

-

Avoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

.png;maxWidth=970;quality=90)