Bad Power is the Root of Many Plastics Production Problems

Sponsored ContentUndetected plant power problems cost plastics processors $9.6 billion a year in preventable equipment failure, downtime and excessive energy costs. This inexpensive power monitoring and analysis system can find problems before the damage is done.

Share

If you run a plastics processing operation, you know that motors burn out, transformers fail, controls suffer memory loss. Sure it’s disruptive, and expensive, but you fix the equipment and move on. It’s just part of doing business, right?

Learn how you can easily and cost consciously diagnose your power quality problems.

But what if you could identify and correct many of the root causes of premature equipment failure? And what if you could lower your utility bill in the bargain?

You can. You just have to pay attention to something most plastics processors rarely think about; your plant power system. According to the Electric Power Research Institute, power quality problems cost U.S. manufacturers up to $188 billion a year—$9.6 billion in the plastics industry alone—with 80 percent of those problems created by manufacturers’ own internal power systems. Bad power is wrecking motors, transformers, electronics and other components way before their times. It’s causing lost production and product quality issues. And it’s unnecessarily driving energy bills up higher and higher.

MachineSense Power Analyzer can diagnose power

issues without the need for expensive diagnostic

equipment and expert technicians.

What can you do about it? For most plastics processors, there hasn’t been a practical or affordable way to stay on top of their plant power issues. But that has changed with the advent of MachineSense Power Analyzer, a power monitoring and analysis system that can help identify and diagnose power issues that heretofore required expensive diagnostic equipment and expert technicians. This new monitoring technology is easy to install, requires little technical expertise to operate and is much less expensive than you’d expect. You can spend just $1,200-$1,300 on a monitoring system that can pay for itself in the first year on power savings alone.

Whitepapers:

Energy Analyics in a Smart Factory Using Machine Sense Power Analyzer

Industry 4.0: Using MachineSense Industrial IoT Platform

What Power Analysis Can Tell You

Plant power problems have been around for a long time. There just wasn't an easy way for most processors to find and fix them. Consequently, there was little awareness of things like power harmonics, transients or other factors that can wreak havoc on your equipment. For example, the vast majority of motor failures are due to power quality problems. Something as seemingly benign as plant lighting can negatively affect computers, controls and other devices. Think PLCs sometimes just naturally lose their programs? They shouldn't, and that’s likely a power quality issue as well.

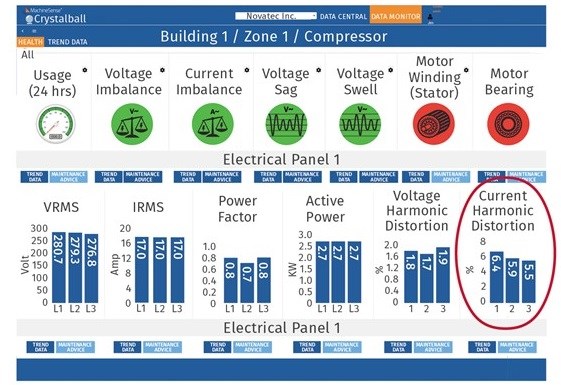

Easy-to-understand dashboards show real-time status of components. Shown here with an optional motor analytics package, a rise in current harmonic distortion caused excess heat to build in motor windings, causing an alarm condition there and in the motor bearings.

With a tool like Power Analyzer, any processor can quickly diagnose the underlying power issues that are causing these and other problems on the plant floor. For example, dealing with these readily detectable, and attributable, power issues will help protect your equipment, reduce downtime and save on energy:

Power Factor – Power factor is a measure of how effectively power is being used, and is the key initial step in understanding your plant’s electrical system. Low power factor results in excessive utility bills by compromising your electrical efficiency.

Bad power can burn out motors, disrupt controllers, and damage transformers, capacitors and other components.

Harmonics – Caused by variable frequency drives, power supplies and other solid-state components, harmonic distortion can result in blown fuses, reduced capacitor life, reduced motor life, inability to operate to full motor load, reduced transformer life, and lost production through overloads tripping and logic faults in machine controls.

Sag – Power sags are typically caused by starting up large equipment, such as high horsepower motors or HVAC equipment, connected to the same power line. The initial interruption of full power can result in poor product quality of machine output, such as an extrusion process. Worse, improperly configured power sag compensators can generate an inrush of current that can damage equipment or falsely activate protection devices.

Swells – The opposite of sags, swells can cause data errors, flickering lights, electrical contact degradation, semiconductor damage and insulation damage. Swells can destroy electronic equipment and drives.

Power Usage – Monitoring power usage is a great way to benchmark your power consumption patterns over time to identify targets for cost reduction as well as document changing conditions in your process equipment. It can also be used to detect serious harmonic issues that can be caused by solid state drives, lighting or other electrical devices.

Webinar:

Poor Power Quality: The Largest Cost Reduction

Opportunity in the Plastics Industry Today

Continuous 24/7 Monitoring

Historically, plastics processors had little choice but to bring in outside electrical consultants with the knowledge and instrumentation to diagnose plant power problems. Since that’s an expensive proposition, it’s often a course of last resort, and it still may not ferret out problems that are transitory in nature.

With MachineSense Power Analyzer, the diagnostics are performed continuously, and the analysis comes back in a form you don’t need an electrical engineer to understand. The system’s simple dashboard conveys critical information at a glance, and offers plain English explanations for likely causes of non-conforming conditions. That, of course, helps identify immediate problems. But the system’s Crystalball software also provides a means to discover recurring problems that don’t present themselves over a short period of time. For example, in one case it helped a stretch-film processor identify a recurring power drop problem that only happened at night.

The software also creates a baseline profile to which equipment can be compared over time. This data can be used to monitor the health of major components such motors, heating units, pumps and more. With the optional ComponentAnalyser, the system can even keep tabs on mechanical components such bearings, gearboxes and valves. Combined, the system can predict impending machine and component failures to prevent unscheduled downtime, and send alarms via text or email when significant problems are detected.

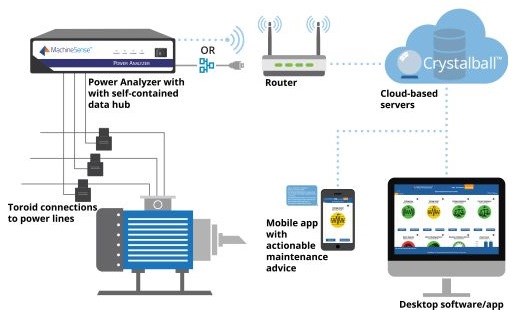

How Power Analyzer Works – Sensor data is uploaded to the cloud-based Crystalball software where it is analyzed and displayed in the form of easy-to-understand dashboards on desktop or mobile devices.

How Does Power Analyzer Work?

It starts with a simple toroid sensor that is clipped around the power lines of all significant electrical machine components. The sensors are hardwired to a data hub that wirelessly connects to a plant floor router. The power consumption data is then sent to the cloud-based Crystalball software for analysis. The software automatically translates complicated electrical graphs into the intuitive dashboards available on desktop or handheld devices.

Power Analyzer can even provide a full cost analysis of your power consumption. Plug in the electricity rates from your utility company, and you can see your consumption in real dollars as well as kilowatts. Now you can visualize power cost, not just on a per-hour basis, but also per unit of production.

Because it is a diagnostic tool, the one thing Power Analyzer doesn't do is recommend solutions to specific problems. To handle that aspect of fixing power problems, MachineSense has assembled a partner network of service companies with expertise in power quality solutions. Using Power Analyzer as the ‘MRI’, these service providers can fix load issues or install devices to protect your equipment such as surge protectors, additional capacitors and so on.

With MachineSense Power Analyzer, you can finally get at electrical problems that may have festered on your plant floor for years...and that cost you real money. To see how, find out more in the PTOnline Power Quality Knowledge Center, the MachineSense Power Analyzer website, or contact MachineSense directly.