Plastics processors realize that purging is a necessary evil and that every moment of downtime translates into lost profits. This raises the obvious question of “how to be proactive” in eliminating black specks, carbon buildup and degraded resin, and minimizing the need to stop production. Understandably, it is difficult to convince any processor to break into a production run to perform a purge cycle. However, controlling the issues is the ultimate goal and requires a program that is proactive rather than defensive.

Creating resin degradation or carbon buildup is directly related to process conditions, equipment and materials that determine the approximate time in the process that degradation takes place. Scheduling a purge to break that cycle prior to the event is the most logical approach to a successful purge program.

Primary Cause of Carbon Buildup

Most often, the course of purging begins with an existing issue that has manifested in a specific area of the screw. Contamination is the result of layers of resin degradation that develop into a buildup in dead spots or negative-flow areas of the screw. As the process continues, the degradation forms layers that become a black or discolored, glass-like substrate that grows more solid, collects and retains heat, and attaches more securely to the metal.

Despite the common perception that purging with resin or continuing through production will remove or dislodge such accumulations, this approach only multiplies the buildup process. Typically, this creates a situation where the degradation area swells into the positive-flow area and releases the contamination into the resin flow, creating black or discolored particles that begin to appear in the part.

Color and additives may be a contributing factor, as well. Color introduced to the resin contains pigment particles, each with individual characteristics that respond to temperature, shear, and melt flow. These pigments are typically selected by the color supplier for their compatibility with a resin system, process and part application.

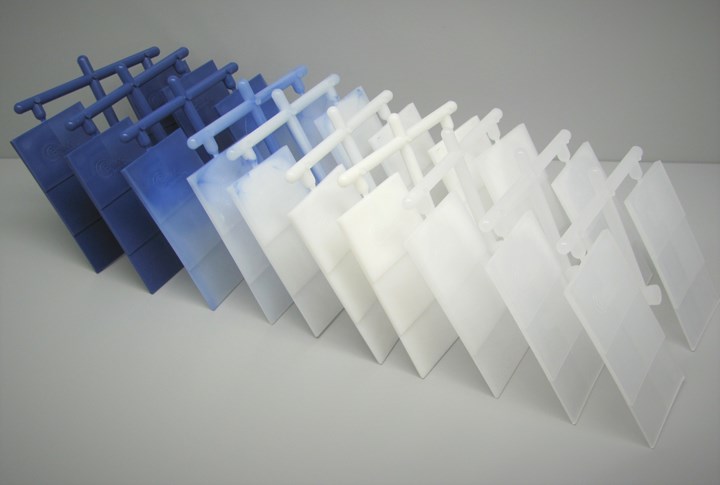

Color chips illustrating purge cycle.

However, pigments are free-flowing particles, and although they are stable for the specific process temperature, once these pigments get entangled in the negative-flow area of the screw, they become exposed to continuous elevated temperatures that may change their actual color appearance. As they break loose and travel into the melt stream of the polymer and blend with unaltered pigment particles, they create an obvious distortion of the intended color, generating part rejects.

Other contributing factors to degradation buildup are screw and barrel wear. Pits or cavities on the screw or grooves in the barrel—no matter how small—become gathering points for resin degradation. Once resin is deposited and becomes idle, it is exposed to resident heat and begins the degradation cycle that results in carbon buildup. Once these deposits swell outside of the void area, they release into the melt stream as a contaminant, polluting the aesthetic appearance of the plastic.

Pits or cavities on the screw or grooves in the barrel—no matter how small—become gathering points for resin degradation

This process then develops into a progression of incalculable conditions that chronicle something like what is shown in Fig. 1.

This scenario relates to two-thirds of the cycle being associated with cost and only one-third generating profits. Although these ratios may vary, this situation most often relates to unpredictable production downtime, impulsive resin losses (since the common perception is to run more resin in attempt to remove or release contamination), and idle production resources.

Obviously, the most rational approach to reducing downtime associated with carbon buildup is to interrupt the process and break the cycle of degradation. The next question is, “When is the right time to break into production?” Unfortunately, there is no one answer for all situations. Because there are so many process variables involved in injection molding, extrusion and blow molding, it is difficult to employ a generic program.

Avoid the common impulse to just keep running more resin through the machine to remove or release contamination.

For this reason, it is important for the processor to communicate with their purge product supplier to develop a pilot program that sets the foundation for an efficient preventive-maintenance program for purging related to the process, equipment and culture of the facility. Most manufacturers or distributors of commercial purging products have the technical resources gathered by testing, past experience or case studies to pass along to plastics processors.

Implementing a planned preventive-maintenance program (PPMP) requires discovery; due to the many variables involved, there is some degree of trial and error. Determining the frequency of breaking into production to eliminate contamination buildup can typically be implemented on a weekly basis, evaluated, then adjusted based on results. This can be done concurrently on multiple machines for a trial period, then adjusted based on the results of that process. Building an effective PPMP will require continuous improvement, an understanding of what purge products to use, collecting and analyzing data, and making adjustments accordingly.

Understand that the types of purging compounds—chemical, mechanical and hybrids—are just like tools in a toolbox. It is highly unlikely that a screwdriver would be used as a hammer or a wrench used to remove a nail. The same is true with purging compounds: Each product has an intended and best-use application. A PPMP begins with determining what tool to use and—more importantly—when to apply it in the process.

A typical PPMP for injection molding most often begins with the plasticating unit of the equipment and transitions into the mold/hot runner. A mechanical purge compound is used to scrub or scour the barrel and screw, followed by incorporating a chemical or synergistic purge compound into any manifolds or hot-runner systems. Integrating a purge into shutdown and startup of production to maintain a clean screw and barrel is a large part of a PPMP and is highly recommended. This practice most often produces an immediate reduction in the contamination buildup cycle and generates a positive starting point for the PPMP.

A PPMP begins with determining what tool to use and—more importantly—when to apply it in the process.

Figure 2 demonstrates a vast reduction in downtime associated with contamination issues related to degradation and carbon buildup with a PPMP in place.

In a recent case study completed by Britec Solutions, an injection molder in Ohio was experiencing excessive downtime due to black specks and other contamination issues on a PP food-storage container. Color concentrate was used to tint the containers in a variety of translucent colors on a 750-ton press with a multi-cavity hot-runner mold. Resin usage was 40% higher than required—representing a waste of 13,360 lb through futile attempts at purging with natural resin—and part rejection was reaching levels of 12%.

A PPMP that consisted of an initial purge cycle on the barrel and screw using a mechanical purge compound designed to scrub and remove stubborn carbon buildup was performed at the onset. After three 24-hr shifts, production was interrupted for a 16-min purge cycle using a different grade, a hybrid purge compound that combines the key features of both mechanical and chemical agents. The purge began with the screw and barrel, then transitioned to the hot-runner mold system before returning to production.

Another purge cycle was implemented for each color change, using both purging grades.

In addition, a purge cycle was employed each Friday at the end of shift to seal the barrel and screw, again using the hybrid grade. After implementing this PPMP with these two compounds, part rejects were reduced to less than 1%, resin consumption was reduced by 56% and machine downtime was cut by over 67%.

This and other case studies show that a PPMP produces significant reductions in downtime, cost savings in resin and color consumption, increased production numbers, and improved efficiencies for plastics processors.

ABOUT THE AUTHOR: Brian K. Cochran is president of Britec Solutions Inc., Tyler, Tex. With more than 35 years of experience in the plastics industry, Cochran is a technical developer specializing in milling equipment for pigment particle-size reduction and distribution, and also a Plastics Engineer with extensive experience in plastics processing, formulation of pigment carrier systems, purge compounds, plastic additives and color technologies. Prior to Britec Solutions, Brian was founder and president of Polytech Color and Compounding, a manufacturer of color concentrates, liquid color and specialty compounds in Ontario, Calif. He founded Britec Solutions in 2010, primarily as a consulting and product-development firm. Since 2019, Britec has been supplying its own line of liquid colorants and additives and BritePurge purging compounds. Contact: 903-707-7471; brian@britecsolutions.com; britecsolutions.com.

Related Content

Asahi Kasei Plastics North America Welcomes New President and COO

With APNA’s president and COO Todd Glogovsky’s retirement April 1, his successor will be v.p. of commercial sales Phani Nagaraj

Read More10 Ways to Improve Twin-Screw Compounding Performance

There are many techniques known to operators and plant engineers for increasing the performance of a twin-screw compounding extruder.

Read MoreHow to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

Read MoreMarket Changes Spur Industrial Recycler to Enhance Capabilities in Clear Plastic Reprocessing

Butler MacDonald found new business and flexibility thanks to a big step-up in purging efficiency.

Read MoreRead Next

Follow These Tips to Power Up Your Purging Process

A properly executed purging process can save processors thousands a year in lost production while helping them increase output and avoid scrap. Here’s how to optimize your results.

Read MoreTry This Lower-Cost Purging Method

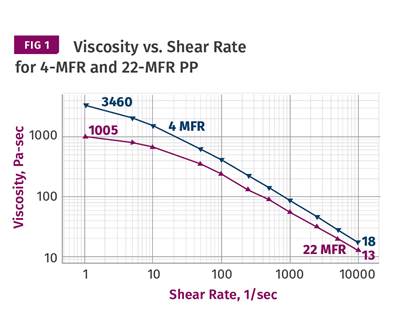

You might be able to reduce purging times and save money by scheduling processing jobs in order of the increasing material viscosity. But to get started, you'll need shear rate/viscosity curves for your polymers.

Read MoreFollow These Steps to Purge Accumulator-Head Blow Molders

Preventive purging with a commercial product between resins or colors and during normal shutdown and startup cycles can prevent excessive loss of resin and production time.

Read More

.png;maxWidth=300;quality=90)