Can Manufacturing Simultaneously Add Robots and People?

According to a study released in Germany, the answer is yes.

In addition to quantifiable gains in productivity and quality, automation has consistently proven to increase something else: anxiety. Robotics, thanks in part to the rise of artificial intelligence (AI) have entered into the general public’s and mainstream media’s consciousness with stories that attempt to predict what jobs might become automated, prompting headlines like these:

- Robots: Is your job at risk?

- Robots to destroy jobs and lower wages, says new study

- How robots will even affect the jobs of people we though were immune

Given the general tone of the automation discussion lately, you can understand why the headline for a recent press release from International Federation of Robotics (IFR) caught my attention:

So, yeah, consider the source—the IFR certainly has a dog in this fight—but the release concerned a report by the Centre for European Economic Research (ZEW) commissioned on behalf of the German Federal Ministry for Education and Research (BMBF); the latter being presumably interested in an unbiased assessment of the impact robotics have had on the German economy.

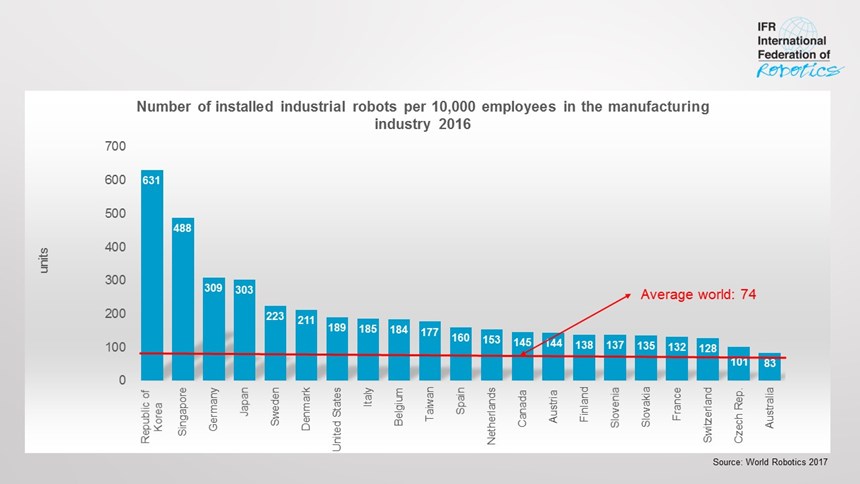

Robot density (number of robots/10,000 employees) in Germany in 2017 was 309 units, third highest worldwide. German employment in 2017, meanwhile, registered at 44 million—its highest level since reunification of the country. In the release, Junji Tsuda, IFR’s president, said Germany’s experience with automation applies beyond that country.

“The modernization of production shifts hazardous, unhealthy and monotonous work to the machines. In the vast majority of cases, only certain activities of a job are automated and not the entire spectrum of an employee’s work.”

The ZEW report also noted that if jobs are eliminated due to automation, as 5 percent of employees were replaced within five years, the employment losses were compensated for by new jobs overall. Going forward, ZEW estimates that further automation and digitalization in manufacturing will generate a 1.8% rise in employment by 2021.

Further bolstering its case, the IFR release called out a recently published London School of Economics (LSE) study entitled Robots at Work. Examining the use of industrial robots in 17 developed economies between 1993 and 2007, that study found that over that time, productivity has improved by around 15% due to industrial robots, while the proportion of low-skilled labor dropped and pay increased slightly.

Automation Adoption Accelerates Around the World

In February, IFR released a survey capturing automation levels around the world. Globally, robot density stood at 74 robot units per 10,000 employees, up from 66 units in 2015. Geographically, average robot density in Europe is 99 units, while coming in at 84 in the Americas and 63 in Asia.

Between 2010 and 2016, the average annual growth rate of robot density in Asia was 9 percent, with 7 percent in the Americas and 5 percent in Europe. In Asia, Chinese utilization of robotics is growing in leaps and bounds, jumping from 25 units in 2013 to 68 units in 2016. China’s robot density currently ranks 23rd worldwide, but the government’s goal is to push it into the world’s top 10 most intensively automated nations by 2020.

Robot density in the United States jumped to 189 in 2016, placing the country seventh in global rank. Going forward, robot sales in the United States will continue to increase through 2020, with forecast growth of at least 15 percent on average per year. I suspect that growth in automation will also correlate with in an increase in robot-fear-mongering headlines.Related Content

A Cost Saving Modular Approach to Resin Drying Automation

Whether implementing a moisture-sensing closed-loop system for a single dryer, or automating an entire plant, technology is available to take the guesswork and worry out of resin drying. Using a modular approach allows processors to start simple and build more capabilities over time.

Read MoreFive Ways to Increase Productivity for Injection Molders

Faster setups, automation tools and proper training and support can go a long way.

Read MoreAutomation Evolution: From Robots to Work Cells, Solo Devices to Integrated Systems

Injection molding automation has progressed from devices to systems, from simplicity to more complex capabilities. The author traces this development through various levels of automation – all still available choices today – and analyzes the costs and capabilities for each level.

Read MoreSystem Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.png;maxWidth=300;quality=90)