Contraction Slows Among Processors

Improvement in fourth-quarter new orders suggest a production boost may be in the offing.

Gardner’s Plastics Processing Index increased marginally to 46.7 in December, indicating a slowing contraction in plastics processing business activity. (Index readings above 50 indicate expanding activity while values below 50 indicate contracting activity. The farther away a reading is from 50 the greater the change in activity compared with the prior month.)

An analysis of the underlying components of the Index for the month found that new orders, production and exports propped up the Index, which is calculated as the average of its components. The Index was bogged down by employment, supplier deliveries and backlogs. All components for the month recorded contractionary activity levels.

FIG 1 Plastics processing business activity, according to December’s survey data, pointed to a moderating rate of contraction. New orders and production posted the highest readings among all components.

Excluding October’s new orders, every index component during the fourth quarter of 2019 was contractionary. No other time in the 8-yr history of the Index has seen such a broad-based contraction.

Gardner’s Plastics Processing Index, which has reported contracting activity since July, has been a leading indicator of the U.S. Industrial Production Index for Plastics Production published by the Federal Reserve. The latest production reading reported a November decline of 1.93% vs. the same month in 2018.

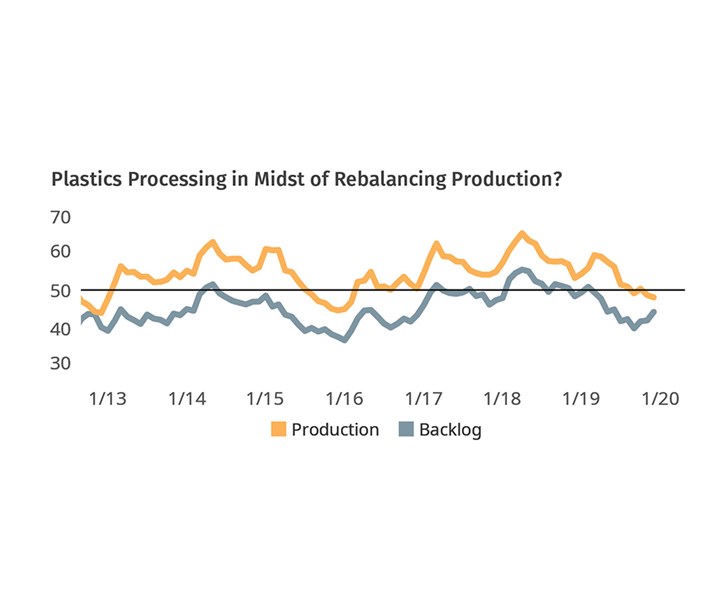

FIG 2 In the last three months of 2019, new orders posted higher monthly readings than production. This may in part explain the improvement in fourth-quarter backlogs, which touched a 3-yr low in September.

The Index is based on surveys conducted each month of subscribers to Plastics Technology Magazine.

ABOUT THE AUTHOR: Michael Guckes is chief economist and director of analytics for Gardner Intelligence, a division of Gardner Business Media, Cincinnati. He has performed economic analysis, modeling, and forecasting work for more than 20 years among a wide range of industries. He received his BA in political science and economics from Kenyon College and his MBA from Ohio State University. Contact: (513) 527-8800; mguckes@gardnerweb.com. Learn more about the Plastics Processing Index at gardnerintelligence.com.

Related Content

-

Why Compression Ratio is Important

Compression ratios have been pretty much standardized over the years, based on what has typically worked before. But there are quite a few variables that must be considered in order to get the optimum performance from your screw.

-

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

-

The Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

.jpg;width=70;height=70;mode=crop)