Decoding ‘Industry 4.0’

The biggest splash at NPE will come from the wave of technological innovation and futuristic enthusiasm known variously as Industry 4.0 or the Smart Factory or the Internet of Things.

It may seem early to most of you, but we editors here at Plastics Technology are already hard at work preparing for NPE2018, the giant plastics show coming up May 7-11 in Orlando, Fla. In doing even the most preliminary research on what exhibitors plan to display, one thing seems certain: The biggest splash at NPE will come from the wave of technological innovation and futuristic enthusiasm known variously as Industry 4.0 or the Smart Factory or the Internet of Things.

That wave has charged across the ocean from Europe, where new protocols for machine-to-machine and machine-to-central-computer communications are being developed under the leadership of the German machinery association, or VDMA.

Although much of plastics machinery used here comes from Europe, the concept of Industry 4.0 has not achieved the same degree of familiarity on this side of the Atlantic. “Molders here are more at the stage of ‘What is it, and why do I need it?’ They want to know how much change it will bring to their operations, what it will cost, and how they will benefit,” says David Preusse, president of Wittmann Battenfeld, Inc., Torrington, Conn.

Jim Healy, v.p. of sales and marketing for Sepro America, Warrendale, Pa., agrees that the banner of Industry 4.0 may fly over many machinery booths, but the attitude of U.S. visitors will be mainly one of curiosity. “They’re on a fact-finding mission to learn about what it means and what it means to them. If Industry 4.0 is about connectivity between machines, then robots have been ‘Industry 4.0’ for years, thanks to standardized control protocols. That connectivity goes several steps further in automation cells that may involve not only a molding machine and a robot, but also insert feeders, secondary robots, complex end-of-arm tooling, in-mold sensors or vision systems, post-mold handling, inspection, finishing, stacking, and packing.”

Adds Preusse, “Industry 4.0 will likely be the most common theme found at NPE. Companies will illustrate how they are using elements that tie into this new Smart Factories era.” He said these can include:

- Molding cells with the robot, press, and auxiliaries all connected together;

- Mold setup recipes for robots and other auxiliaries stored on the injection machine for faster mold changes;

- Web service support;

- MES collection of production data;

- Smartphone apps to get production status or alerts;

- Predictive-maintenance monitoring of cell equipment;

- “Smart molding” process solutions;

- Production traceability;

- Remote access and control.

That’s an awful lot to digest, and Chris Parrillo, national sales manager of Yushin America, Inc., Cranston, R.I., thinks the best way for molders—especially those from small to mid-sized firms—to approach the topic is to “break it down into manageable chunks.”

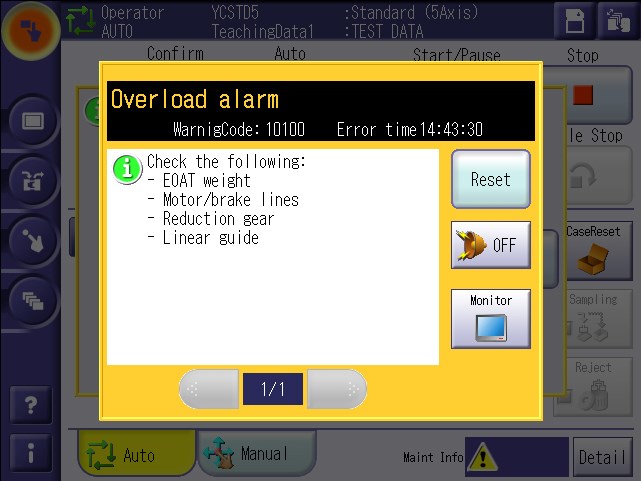

One of those chunks is predictive maintenance, which is an emerging theme that will be sounded by injection machine suppliers (see our previous reporting on Engel, Milacron, and Wittmann Battenfeld) and builders of auxiliary equipment (notably Novatec and MachineSense/Prophecy Sensorlytics). The idea is for a robot “to monitor its own internal systems and detect problems as they develop, so it can warn of a maintenance issue before a catastrophe strikes on a weekend shift,” explains Dino Caparco, Yushin’s engineering operations manager.

Some of the first signs of this trend in robots will be appearing at NPE, including some brand-new announcements. For example, look for features such as Wittmann’s new monitoring of gripper vacuum levels to warn of leaks or other problems before the robot loses its grip (see Sept. ’17 Keeping Up). Other approaches may include vibration sensing and monitoring servomotor torque and amperage load to detect bearing misalignment, insufficient lubrication, damaged rails, and/or fatigue of the robot arm due to repeated flexing.

Another closely related “chunk” of Industry 4.0 is remote monitoring and web-service support. Such features have become increasingly common for molding machines and are now spreading to robots. Sepro’s new Live Support is an example (see Jan. ’18 Starting Up).

Still another related trend under the broad umbrella of Industry 4.0 is varying degrees of integration of robot controls with those of the injection press, which can range from “mirroring” of the robot control interface on the operator panel of the press to actual sharing of data between the robot and press—a more complex issue when different vendors are involved. Wittmann Battenfeld, whose “Wittmann 4.0” program integrates its injection machines, robots, and auxiliaries, plans to demonstrate “dynamic changeover of peripheral equipment with mold changing applications to quickly plug and produce, on saved recipes,” according to Preusse.

Says Sepro’s Healy, “How Industry 4.0 evolves is really up to molders, and we think that they are still trying to discover how they can benefit from these evolving technologies. That’s why, rather than attempting to define Industry 4.0 for them, Sepro is committed to remaining open to all ideas. “We collaborate with customers to develop new tools—like OptiCycle and Live Support—that make their operations more efficient. We work with machine manufacturers to flexibly integrate robot control with IMM controls and offer packaged systems to customers who want them. We partner with other robot companies to give molders the widest choice of robot configurations, sizes, and capabilities. And we support research into the next generation of robot technology, working with institutions in Europe and the U.S. In summary, we at Sepro believe that Industry 4.0 demands that people, machines, and companies ‘connect’ in much more significant and powerful ways, ways that allow them to perform to their highest potential.”

NPE won’t be the only place where Industry4.0 will make a splash. It will be a prime topic of technical presentations at Plastics Technology’s Molding 2018 Conference, Feb. 27-Mar. 1 in Long Beach, Calif. Get program and registration details here.

Related Content

50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read MoreFive Ways to Increase Productivity for Injection Molders

Faster setups, automation tools and proper training and support can go a long way.

Read MoreDrones and Injection Molding Ready for Takeoff

Drones and unmanned aerial vehicles (UAV) are approaching an inflection point where their production volumes — and functionality — will increasingly point to injection molding.

Read MoreEnsuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More