DME Moves Closer to Molders & Moldmakers in Mexico

DME sets up permanent office to support Mexico's fast-growing plastics industry.

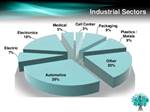

Mexico appears to be enjoying a surge in plastics business, supported in part by its growing cost-competitiveness with Chinese processors and the “reshoring” or “near-shoring” trend, as we have noted in recent posts. To support Mexico’s growth in plastics, DME, Madison Heights, Mich., has established a permanent presence within Milacron’s High Impact Technology Center in Querétaro, 220 km north of Mexico City. DME now sells directly to customers in Mexico through the 10,000 ft2 facility, which has a full-time staff of 32. It is stocked with the most popular DME products and replacement items. The center also has classrooms for educational sessions and a showroom displaying a variety of Milacron plastics technologies. DME also has direct sales representatives in Mexico City, Guadalajara, and Monterrey and has a Spanish-language website, where customers can view and, later this year, order DME mold bases, plates, components, hot runners, temperature controllers, and more.

Related Content

-

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

-

What You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

-

Where and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.