Collaborative Program Converts Hard-to-Recycle Plastics into Energy Resources

Q&A with Dow’s Jon Pyper on the process, success stories and long-term goals of a new program to turn things like chip bags into energy, including diesel fuel.

There is some exciting recycling innovation happening right now with plastic packaging that previously wasn’t recycled. The Hefty EnergyBag program, launched by Dow Packaging and Specialty Plastics, Midland, Mich., offers an innovative approach to diverting plastics that are not currently recycled—such as chip bags and juice pouches—from landfills and converting the materials into valuable energy resources.

Jon Pyper, Dow’s North America Associate Director, Sustainability & Advocacy, Packaging & Specialty Plastics shares success stories and long-term goals.

Q: How did the idea for the Hefty EnergyBag come together?

A: Plastic packaging provides great sustainability advantages in the use phase of its life cycle. However, beyond the plastics industry’s best efforts to increase diversion rates through mechanically recycling, too many of these materials were ending up in the landfill, and we felt something else was needed to extend the life of these valuable materials.

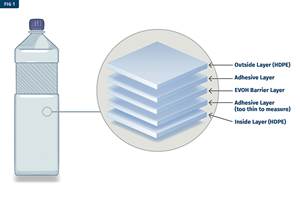

A number of plastic articles are unable to be mechanically recycled at their end-of-life phase due to a variety of reasons, including the fact that many flexible packages are made of high performing multi-material laminate structures; recycling infrastructure that does not target collection of hard-to-recycle plastic packaging; the limited sorting capabilities at a materials recovery facility (MRF); and the under-developed end markets that are possible for these materials.

To address these challenges, Dow, in partnership with Reynolds Consumer Products, decided to collaborate and find ways to overcome some of the obstacles and allow more of these hard-to-recycle plastics to be diverted from landfills. Dow, as one of the largest producers of polyethylene, led the development of the Hefty EnergyBag program, which allows these materials to be collected at the curb and easily pulled out and sorted at MRFs to be converted into valuable resources, thereby extending their life cycle.

Q: Can you detail how the process works? What types of plastic are gathered?

A: The program is very simple for the consumer, but relies on a strong collaboration with the MRF, hauler and municipality to make it a win for everybody involved.

Participating households receive a roll of Hefty orange bags, which is typically enough for a year supply. As consumers collect their normal recyclables, they put plastics that can’t be recycled through regular mechanical recycling into the Hefty orange bags. Once the bags are full, residents tightly tie the bags closed, put them in their recycling cart along with the other items that are collected, and take them all out to the curb on the day of their regularly-scheduled recycling pick up. It’s as easy as 1, 2, 3 – Collect, Close and Capture the value of these plastics rather than send them to the landfill. The bags are picked up by the regular hauler and sent to the usual MRF, where the bags are pulled out at the front end and shipped to approved end-market facilities. These plastics that are diverted from the landfill are then converted into a valuable resource, such as diesel fuel.

The program is complementary to existing recycling programs and uses the mechanical recycling infrastructure of carts, hauler and MRF, making this recovery program easy for all the stakeholders. It’s important to note that the orange bags are never opened and never go through the MRF, which helps reduce the amount of loose flexible plastic packaging entering the MRF. This benefits the MRFs by keeping their recycled materials cleaner and their overall operations more efficient.

Q: Where all is this program implemented? Are there success stories you can share?

A: In 2014, Dow, the Flexible Packaging Association, Republic Services and the City of Citrus Heights, Calif. sponsored a three-month pilot program. The pilot was the first of its kind in the United States to collect hard-to-recycle plastics at curbside and divert them from landfills in this way. Materials collected during the Citrus Heights program were converted into high-value synthetic crude oil at a local plastics-to-fuel plant. Since launching permanent programs in late 2016, we currently are collecting hard-to-recycle plastics in a number of communities including Omaha, Neb. and the surrounding communities of La Vista, Ralston, Louisville, Oakland, Bellevue, as well as Boise, Id. Additionally, we have plans to launch the program in Cobb County, Ga. later in 2018.

Participating communities have clearly proven that this program works; that they can reduce the amount of plastics going to landfills and that MRF operators can reduce the amount of loose flexible plastics coming into their facilities, thereby making their regular recyclable material cleaner.

In fact, the recent ban on recycling imports into China has brought additional visibility to the value and success of the existing Hefty EnergyBag programs. The ban eliminated a major end market for North American recyclers and thus reduced the value of recycled materials. Communities are being faced with the reality and expense of sending much of their #3-7 plastics to the landfill. Although the Hefty EnergyBag program focuses primarily on collecting flexible plastics, communities could avoid this financial and environmental expense by expanding the program to collect flexible plastics as well as the #4-6 rigids in the orange bags.

Through June 2018, we have collected over 135,400 orange bags and diverted ~ 88 tons of hard-to-recycle plastics from going to landfills. This is equivalent to over 70 million snack-sized chip bags or 419 barrels of diesel, enough to power 49 cars per year!

Q: Which energy recovery facilities are you working with on this initiative?

A: Dow supports all stages of the EPA’s Waste Management Hierarchy of Reduce, Reuse, Recycle and Recover. The fourth ‘R’—Recover—is sometimes overlooked but is an important aspect of the waste management process, particularly for hard-to-recycle plastics.

We are currently working with pyrolysis technology providers who can convert the hard-to-recycle plastics to diesel fuel, thereby reducing the need to mine and extract virgin oil and natural gas. Pyrolysis technology is a chemical reaction where plastics are heated in an oxygen-free chamber and converted to valuable resources. When no pyrolysis unit is available, communities participating in the program have used other viable energy recovery technology, such as a cement kiln, as an alternative to capturing the value of the collected plastics.

Q: What’s the long-term goal for this initiative?

A: Since we have proven the program works, our immediate goal is to grow the Hefty EnergyBag program by adding more communities across North America so that the life cycle of these hard-to-recycle plastics are extended and they are diverted from landfills. For instance, Dow collaborates with Keep America Beautiful to provide grants to communities looking to implement the program in their area.

Related Content

Measuring Multilayer Plastic Containers Made Easier With Today's Ultrasonic Gauges

Ultrasonic gauge technology has evolved to simplify measurement of very thin layers in plastic containers. Today’s gauges with high-frequency capabilities and specialized software can make multilayer container measurement quick and easy for ordinary users.

Read MorePregis Performance Flexibles: In the ‘Wow’ Business

Pregis went big and bold with investment in a brand-new, state-of-the-art plant and spent big on expanding an existing facility. High-tech lines, well-known leadership and a commitment to sustainability are bringing the “wow” factor to blown film.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More

.png;maxWidth=300;quality=90)